8

• Ensure the ‘outdoor’ extension cord is not placed

accross walkways so that it is not a trip hazard.

• Do not use in damp or wet conditions.

• Always ensure that the power cord is fully extended

and NOT in contact with any part of the spit.

• Never use the motor if any part of it is damaged.

• Do not attempt to modify the motor, power cord

or power plug in any way.

• This product is

fitted

with a sealed electrical

connection plug that is compatible to the mains

supply for New Zealand and meets the

requirements of international standards. It must

be connected to a supply voltage that is equal to

that stated on the rating label. If the mains

connection plug or power cord becomes

damaged it must be replaced with a complete

assembly that is identical to the original, and this

must be replaced by an authorised service

centre. Always follow the New Zealand

requirements for connection to the mains supply.

If in doubt alwa

ys consult a qualified electrician.

CARE & MAINTENANCE

Care & Maintenance

As with all appliances, proper care and

maintenance will keep them in top operating

condition and prolong their life. Your new gas

spit roaster is no exception. By following these

cleaning procedures on a timely basis, your spit

roaster will be kept clean and working properly

with minimum effort.

Cleaning

“Burning off” the spit roaster after every use

(for approx 15 minutes) will keep excessive food

residue to a minimum.

Outside Surface

Use mild detergent or baking soda and hot water

solution. Non-abrasive scouring powder can be

used on stubborn stains, then rinse with water.

If the inside surface of the spit roaster hood has

the appearance of pealing paint, baked on grease

build-up has turned to carbon and is

flaking

off.

Clean thoroughly with strong hot soapy water

solution. Rinse with water and allow to completely

dry.

NEVER USE OVEN CLEANER.

Interior of spit roaster bottom

Remove residue using brush, scraper and/

or cleaning pad then wash with a soapy water

solution. Rinse with water and alow to dry.

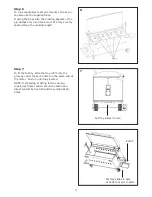

Cleaning the burner assembly.

Turn the gas ‘OFF’ at the control knob and

disconnect the cylinder.

Clean the burner with a soft brush or blow clean

with compressed air and wipe with a cloth.

Clean any clogged ports with a pipe cleaner or stiff

wire (such as an opened paper clip).

Flash-Back

Spiders and small insects occasionally spin

webs or make nests in the burner tubes during

warehousing and transit.

These webs can lead to a gas

flow

obstruction

which could result in a

fire

in and around the

burner tubes. Cleaning with a soft brush

before use and at least every six months is

recommended.

This type of

fir

e is known as ‘FLASH-BACK’ and

can cause serious damage to your spit roaster and

create an unsafe operating condition for the user.

Although an obstructed burner tube is not the only

cause of ‘FLASH-BACK’ it is the most common

cause and frequent inspection and cleaning of the

burner tubes is necessary.

If

fir

e occurs in and around the burner, immediately

turn off gas at its source and turn the burner control

to ‘OFF’, wait until the spit roaster has cooled, then

clean the burner tubes and burner ports.

Cleaning the Fat Tray

To avoid fat or grease dripping from the spit

roaster remove and empty the fat tray after each

use. A small amount of water can be placed in the

fat cup before use to help with fat removal. Wait

until the fat tray is cool to touch before disposing

of contents.

The fat tray should be washed periodically

in a mild detergent and warm water solution.

Service

If the appliance cannot be adjusted to perform

correctly it should not be used until serviced or

repaired. Contact 0800 161 161 for service

information.

IMPORTANT

• Beware of spiders and wasps. Burner tube

should be inspected and cleaned periodically.

• To avoid any

flare-ups,

it is recommended

that the fat tray be checked and emptied

regularly. Contents of the fat tray may be

very hot during cooking. If emptied during

extended cooking extreme caution should

be taken and direct contact by hand should

be avoided at all times. Allow to cool

completely before disposing of the contents.

• This appliance must only be serviced by an

authorised person.

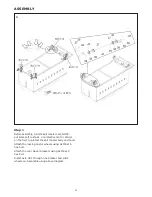

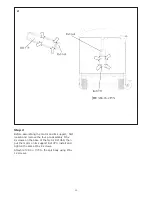

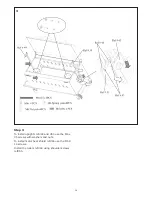

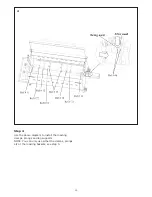

Summary of Contents for GSB300

Page 10: ...10 EXPLODED DIAGRAM ...