(Part No. 233885)

Installation Instructions

Read and follow these instructions (in conjunction with the Jewel / Spectre

Freestanding manual) carefully before installing this appliance.

SAVE THESE INSTRUCTIONS

Sheet

1

of

6

GPN

234969

F:\Docs\Manuals\Heaters\Heaters\GPN 234969 Jewel Spectre Thru Wall

Minimum

requirements

This Heater has been tested to AS2918:2001 Appendix B.

Test Report No. ASFT18004 - 1

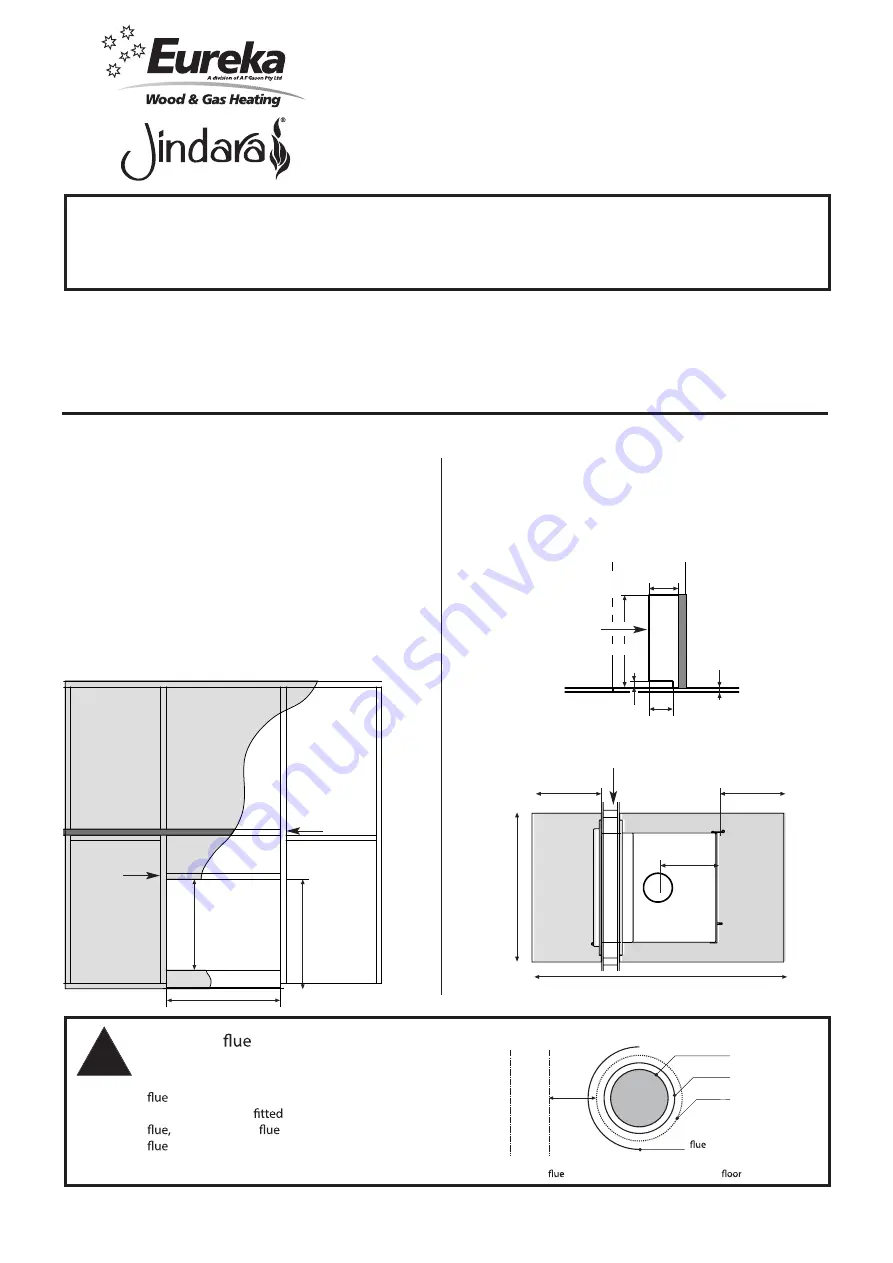

kit.

For the through wall installation additional

8˝ stainless is to be

over the 7˝ stainless active

then a 9˝ mesh

shield and a 10˝ stainless steel

shield are to be installed, both to ceiling height.

(See diagram opposite)

9˝ solid back

mesh

8˝ stainless

7˝ stainless

!

10˝ stainless steel

shield up to

drop box height

NB: First

height 4600 mm (+/– 300mm) from

protector

In

te

rn

al

w

al

l

120mm

min.

These must be used to make the installation conform.

Jewel / Spectre Through Wall Kit

• The installation of this appliance must be carried out as per the manual and the flue manufactuer’s specifications

We recommend that you use a qualified installer to carry out the installation.

• Default clearance values and flue requirements specified in AS/NZS 2918-2001 must be used for any clearance values not

given in these instructions.

• If in doubt, do not hesitate to contact your local Jindara or Eureka dealer.

• This appliance weighs in excess of 230 kilograms. Extreme care should be taken when handling the appliance.

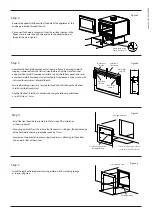

• This thru-wall kit is designed for use with plasterboard stud walls,

with a total thickness ranging between 90mm and 110mm.

• Note that the wall section below the appliance fascia on the insert

side is filled, as per figure 1. It should be supported by a stud with a

10mm x 35mm horizontal cut-out, as per figure 2. This is to allow

the base of the freestanding unit to protrude far enough through

the wall.

Hole cutting dimensions & clearances to combustibles

0$7(5,$/0DWHULDOQRWVSHFLILHG!

),1,6+

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9 %< (&11R '$7(

5(9 %< (&11R '$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

Figure 1

See

Notes 1 & 2

See

Note 3

890 mm

860 mm

714mm

Note 1: If present, a combustible mantle shelf must be positioned

a minimum of 500mm above the apliance hot air outlet.

Note 2: Combustible internal wall framing must not be installed

less than 475mm above the appliance top plate.

Note 3: Non-combustible internal wall framing must be used if

installed directly above the appliance, less than 475mm

from the top plate.

0$7(5,$/0DWHULDOQRWVSHFLILHG!

),1,6+

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9 %< (&11R '$7(

5(9 %< (&11R '$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

Insert

side

35 mm

15 mm

Floor protection

minimum thickness

6 mm

45 mm

110 mm

Freestanding

side

Horizontal lower

support stud

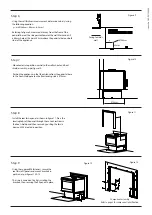

• A minimum 1590mm x 940mm floor protector with a minimum

thickness of 6mm must be installed under the appliance, as per

figure 3.

• The floor protector must extend a minimum of 420mm from each

appliance door and 155mm from the pedestal base on either side

of the appliance.

Figure 2

0$7(5,$/0DWHULDOQRWVSHFLILHG!

),1,6+

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9

%<

(&11R

'$7(

5(9

%<

(&11R

'$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

Internal wall

Figure 3

420mm

420mm

940mm

1590mm

372mm

using an Australian Standard