$

$

6(&7,21$$

0$7(5,$/

),1,6+

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9 %< (&11R '$7(

5(9 %< (&11R '$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

-(:(/63(&75()6

7+58:$//.,7&20%867,%/(:$//

77

(1*35

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

77

Sheet 3 of 6 GPN 234969

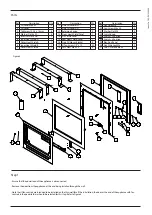

Step 2

• Remove the pedestal fill panel from the base of the appliance, at the

end being installed through the wall.

• Disconnect fan harness connectors from the switches housed in the

fill panel and secure the earth wire eyelets to the pedestal base, at

the point shown in figure 5.

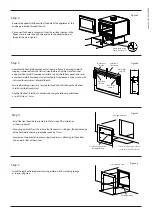

Step 3

• Assemble the heatshield components as shown in figure 6, ensuring all plastic

wraping is removed from the stainless steel before assembly. Note that inner

and outer heat shield A components attach to heat shield front panel, inner and

outer heat shield B components are attached to A components using screws, with

slots used for adjustment of overall depth.

• Ensure all retaining screws are securely fastened and that the depth of the heat

shields is uniformly adjusted.

• Depth of the heat shields

(x

) is determined using the following calculation:

x = wall thickness - 5mm

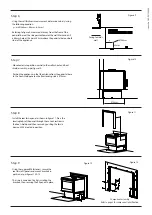

Step 4

• Install the front heatshield assembly to the far side of the installation,

as shown in figure 7.

• Measuring vertically from the surface that the heater is sitting on, the bottom edge

of the heatshield assembly should be raised by 77mm.

• Secure mounting brackets in place using wood screws, attaching to the vertical

stud on both sides of the cut-out.

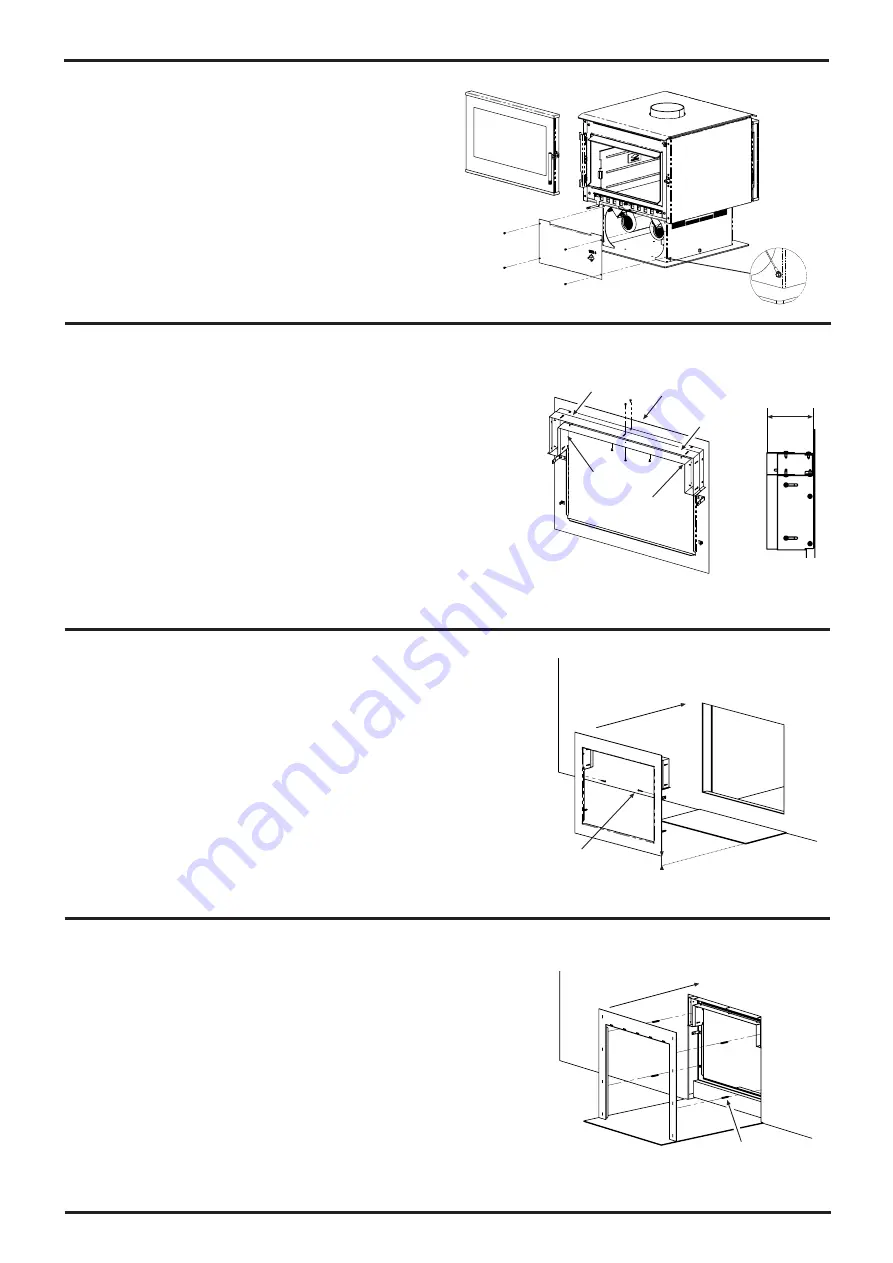

Step 5

• Install the rear heatshield panel, securing in place with 4x retaining springs,

as shown in figure 8.

'

'(7$,/'

6&$/(

0$7(5,$/

),1,6+1$785$/

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9 %< (&11R '$7(

5(9 %< (&11R '$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

'225+($7(5)6

%$6(+($7(5

77

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

'

'(7$,/'

6&$/(

0$7(5,$/

),1,6+1$785$/

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9 %< (&11R '$7(

5(9 %< (&11R '$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

'225+($7(5)6

%$6(+($7(5

77

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

$

$

6(&7,21$$

0$7(5,$/

),1,6+

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9 %< (&11R '$7(

5(9 %< (&11R '$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

-(:(/63(&75()6

7+58:$//.,7&20%867,%/(:$//

77

(1*35

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

77

Attach earth points

firmly using screw

Heat Shield

Front Panel

x

Inner Heat

Shield A

Inner Heat

Shield B

Outer Heat

Shield B

Outer Heat

Shield A

0$7(5,$/

),1,6+

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9 %< (&11R '$7(

5(9 %< (&11R '$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

-(:(/63(&75()6

7+58:$//.,7&20%867,%/(:$//

77

(1*35

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

77

77mm - bottom edge of fascia

to top face of floor protector.

Secure to vertical stud

through brackets

0$7(5,$/

),1,6+

'5$:1

7,7/(

$33'

-,*

6+((7

2)

5(9 %< (&11R '$7(

5(9 %< (&11R '$7(

5(/($6('

'21276&$/(

$

6&$/(

3$571R

-(:(/63(&75()6

7+58:$//.,7&20%867,%/(:$//

77

(1*35

7+,6,1)250$7,21,6&21),'(17,$/$1'5(0$,167+(

3523(57<2)$)*$62137</7'81'(5&23<5,*+7/$:

$)*$62137</7',1&,19,&725,$

5(*,67(5('2)),&(

%/$.(675((7$5$5$7

9,&725,$

0$66NJ

7+,5'

$1*/(

352-(&7,21

67$1'$5'0(75,&72/(5$1&(681/(6663(&,),('27+(5:,6(

',0(16,2166+2:17+86RU

'5,//('+2/(6381&+('+2/(6$1*/(6

)25/$6(5&87&20321(176

)256+((7PP$1'81'(572/(5$1&(

)256+((7WRPP72/(5$1&(

)256+((7WRPP72/(5$1&(

77

(Through wall side)

(Freestanding side)

Figure 5

Figure 6

Figure 7

Figure 8

Retaining spring