USE AND MAINTENANCE

ENGLISH

g

38

cod. G19502491

3.4 DISTRIBUTION

3.4.1 SEED DISTRIBUTOR

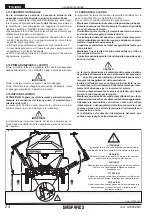

The doser (Fig. 13) the most important part for seeder operation,

is located underneath the seed hopper. Motive power is

transmitted to it by the drive wheel through gears (with ratios

proportional to the width of the work to be carried out) and chains.

Thanks to a gearbox (A Fig. 13) it allows the distributor roller (B)

to operate with two gear ratios, by changing the position of the

red toothed wheel (C Fig. 13, 14, 15). In position «

N

» (Fig. 14),

the gear ratio is 1:1, as imposed by the pair of toothed wheels

Z19; when the wheel (C) is shifted to the «

M

» (Fig. 15) position,

the distributor wheel halves the number of revolutions, as the

drive is then composed of the red drive wheel Z14 and the drawn

wheel Z28. When a dosing test, as described in chapter 3.4.2, is

performed, it may be observed that the quantity of product

distributed is halved (see Table 3-4) compared to the test using

ratio 1:1. The position «M» of the toothed wheel (C) is necessary

for the distribution of small seeds and quantities.

The screw rod (D) enables the degree to which the gate opens to

be adjusted depending on the value of the graduated scale,

calculated using the table and the distribution test (chapter 3.4.2).

The reference element for setting the gate valve opening is point

A (Fig. 19).

ATTENTION

Caution: danger hazard for doser: Set a lower quantity of product

only when the doser is rotating or when the hopper is empty.

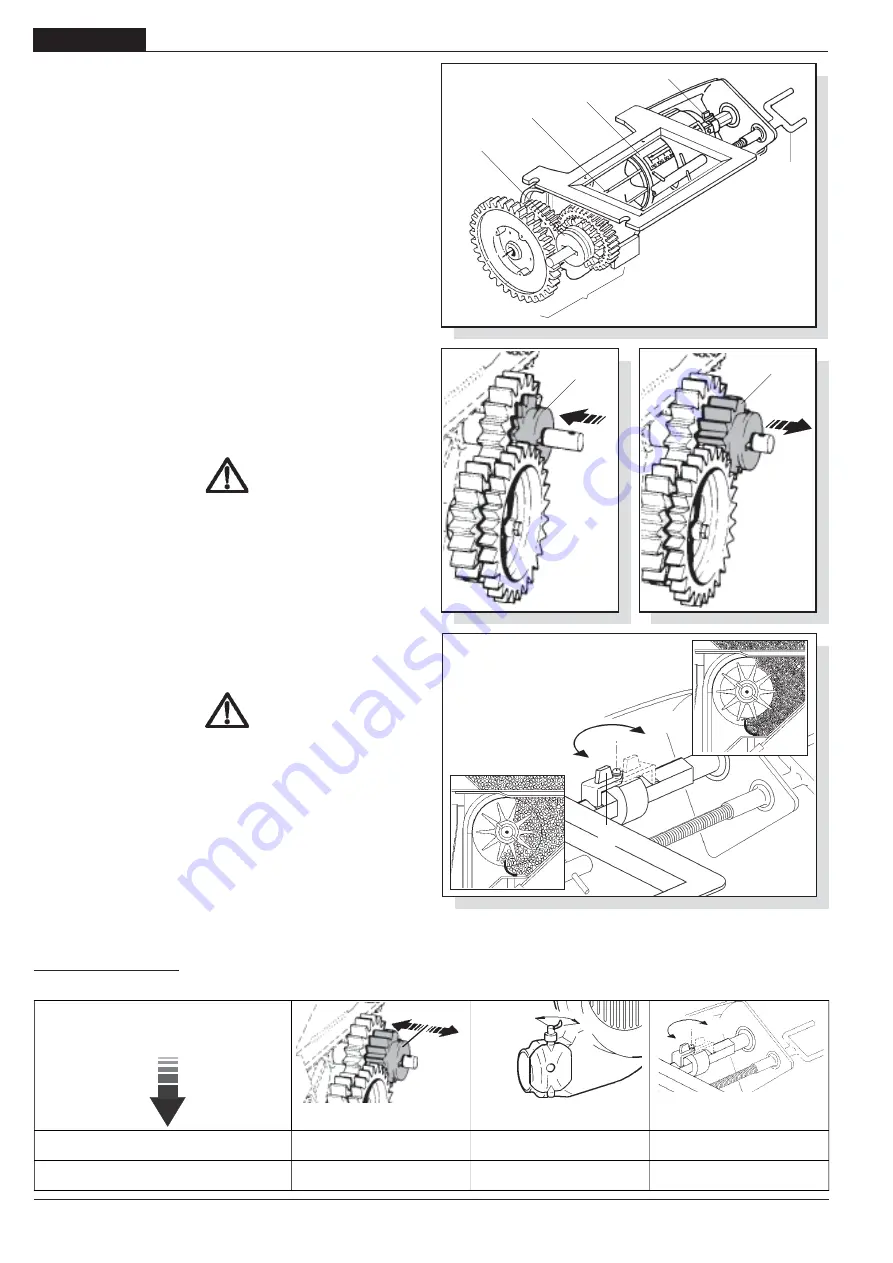

The locking spring (E Fig. 13, 16) enables the opening range of

the gate to be modified which, in turn, modifies the capacity of the

dosing roller at the same time. The position «

E1»

(Fig. 16) enables

the gate to be opened on a graduated scale, ranging from 0 to

110, with maximum capacity of the dosing roller; in the

«E2

»

position, on the other hand, there is a gate opening range of 0 to

25 and the capacity of the roller is reduced. It is important always

to remember to close the gate completely (0 on the graduated

scale) in order to invert the position of the locking spring (

E

).

ATTENTION

Caution: danger hazard for doser: Set a lower quantity of product

only when the doser is rotating or when the hopper is empty.

When correctly placing the locking spring a click will be heard

indicating that the operation has been completed successfully.

3.4.2 DISTRIBUTOR ADJUSTMENT AND TEST

DISTRIBUTOR ADJUSTMENT

The seeding table contains the instructions for suitably

distributing the seeds. The data that must be taken into

consideration for proceeding with the job are: size and type of

seed (small or normal size, e.g. wheat or colza), quantity in kg to

be distributed per hectare.

Size and type of seeds: adjust the distributor according to the

selected seed (see Table 2).

fig. 16

E1

E2

Tipo semente -

Type of seeds -

Saatguttyp -

Type

de sem ence -

Tipo de semilla

D osaggio -

Dosing -

Dosierung -

D osage -

D osificación

Valvola a farfalla -

Butterfly valve -

Drosselklappe -

Vanne-papillon -

Válvula mariposa

Molla di blocco -

Locking spring -

Sperrfeder -

Ressort de blocage -

Resorte de bloqueo

Semente normale -

Norm al seeds -

Normales

Saatgut -

Sem ence norm ales -

Semillas normales

N

A

E1

Semente piccola -

Sm aal seeds -

Klaines Saatgut

Sem ence petites -

Semillas pequeñas

N-M

Z

E2

E1

E2

Z

A

Table 2

Cod. 19703350

N

M

fig. 13

B

D

E

A

C

«

N

»

C

C

«

M

»

F

fig. 15

fig.14

E

Summary of Contents for PINTA

Page 4: ...g 4 cod G19502491...

Page 27: ...g 27 cod G19502491 Notes...

Page 28: ...g 28 cod G19502491...

Page 51: ...g 51 cod G19502491 Notes...

Page 52: ...g 52 cod G19502491...

Page 75: ...g 75 cod G19502491 Notes Notes Notes Notes Notes...

Page 76: ...g 76 cod G19502491...

Page 99: ...g 99 cod G19502491 Notes...

Page 100: ...g 100 cod G19502491...

Page 123: ...g 123 cod G19502491 Notes...

Page 124: ...g 124 cod G19502491...