USE AND MAINTENANCE

ENGLISH

g

47

cod. G19502491

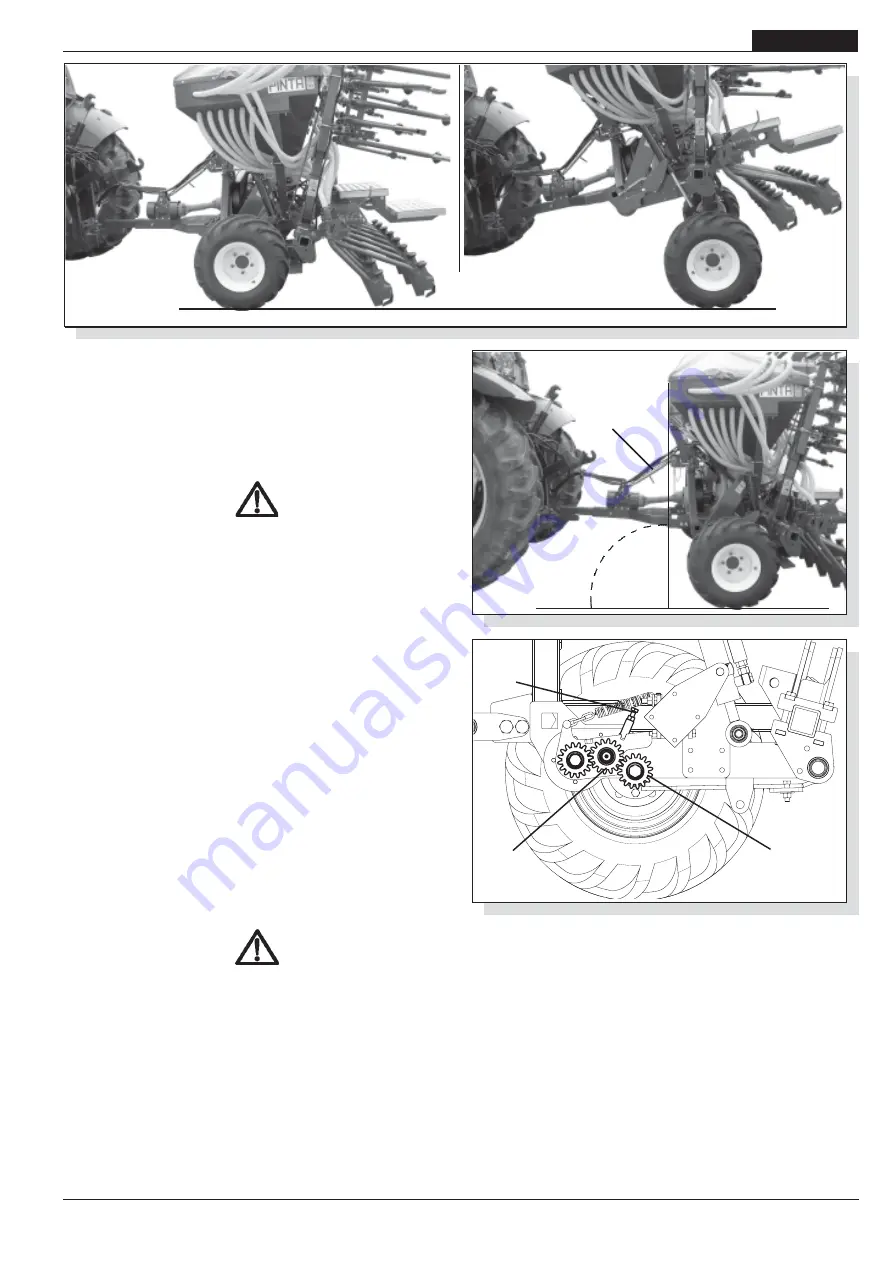

3.12 TRAILED VERSION

On request, the mounted version of the seed drill can be

equipped with a transforming element to make it trailable (Fig.

38). Applicable to tracked tractors, the trailed seed drill is ideal for

planting in hilly areas.

3.12.1 ATTACHMENT TO THE TRACTOR

DANGER

The attachment to the tractor is a very dangerous phase. Be

very careful in following the instructions for the whole operation.

HOOKING

The correct positioning of the tractor/seeder is determined by

placing the unit on a horizontal surface.

1) Attach the equipment to the tractor's load hooking bolt. Secure

the load hooking bolt by means of the safety pin; using the

regulating tie-rod (C Fig. 39) ensure that the seed drill is

perpendicular to the ground (Fig. 39).

2) Connect the Cardan shaft and make sure that it is perfectly

blocked on the power take-off Check that the protection turns

freely and fix it with the special chain.

3) The hydraulic pipes must be connected correctly to the tractor

distributors (see chapter 3.1) following the instructions on

each pipe.

4) Check the length of the grain tubes (with the machine

completely hoisted) to avoid bendings and consequently

breaking of the tube, as well as the formation of loops (Fig.

10).

During the work, regularly check that the equipment is

perpendicular.

UNHOOKING

DANGER

Unhooking the seed drill from the tractor is a very dangerous

operation. Great caution must be used and the whole operation

must be carried out following the instructions.

For a correct unhooking operation of the seed drill it is necessary

to proceed on a horizontal level.

1) Lower the supporting base elements

2) Slowly lower the

seed drill until it rests completely on the

ground.

3) Disconnect the hydraulic pipes from the tractor distributors

and protect the quick couplings with the caps.

4)

Unhook the Cardan shaft from

the tractor and put it on the

special hook.

5)

Detach the equipment from the tractor's load hooking bolt.

TRANSMISSION

The movement is transmitted from the wheel to the dosing device

by meshing the gears (D-E, Fig. 40).

Check that the gears are correctly meshed at the beginning of

the season (presence of "play" between D-E).

If the gears are meshed tightly, adjust the regulating screw (F,

Fig. 40).

Failure to mesh the gears properly could lead to the breaking

of the gear's support shaft (D).

The transmission disengages automatically when the equipment

is lifted to the transporting position (B, Fig. 38).

fig. 40

fig. 38

fig. 39

90°

C

D

E

(A)

(B)

F

Summary of Contents for PINTA

Page 4: ...g 4 cod G19502491...

Page 27: ...g 27 cod G19502491 Notes...

Page 28: ...g 28 cod G19502491...

Page 51: ...g 51 cod G19502491 Notes...

Page 52: ...g 52 cod G19502491...

Page 75: ...g 75 cod G19502491 Notes Notes Notes Notes Notes...

Page 76: ...g 76 cod G19502491...

Page 99: ...g 99 cod G19502491 Notes...

Page 100: ...g 100 cod G19502491...

Page 123: ...g 123 cod G19502491 Notes...

Page 124: ...g 124 cod G19502491...