4.3

ADJUSTMENT OF THE GAS RATE

All the instructions written below are for the exclusive

use of qualified service technicians or installers. All the

boilers are supplied already calibrated and tested.

Ad ustments are only be made with special tools.

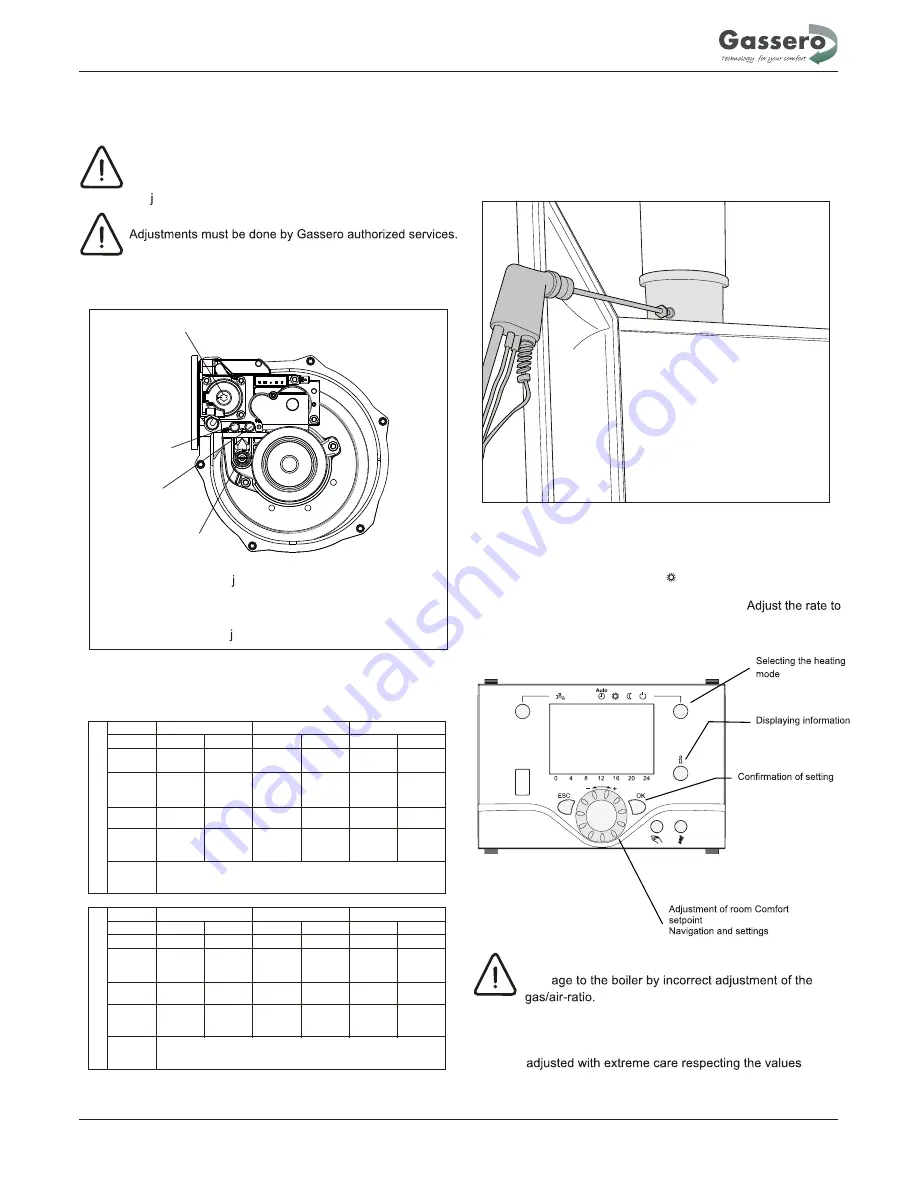

4.3.1 Description of the adjustment points

A - Maximum output ad ustment screw

B - Outlet pressure tap

C - Inlet pressure tap

D - Minimum output ad ustment screw

4.3.2 Combustion values adjustment table

4.3.3

Maximum output adjustment

1 - Connect the gas analyser probe to the sampling test point

on the flue adapter.

2

WARNING:

Dam

To ensure correct operation the values have to be

indicated in the table.

- For operating in the max. output, press at least 3 seconds to

heating mode when the boiler in mode.Controller function stop

will appear on the screen.Than press information button, it will

indicate the modulation rate (%) on the screen.

100% for max. output setting with using of navigation button. Then

press OK . Thus, boiler will operate in maximum power.

Instructions for the installer

16

100 %

B

D

A

C

Model

Q

min.

max.

min.

max.

min.

max.

CO

2

%

8,9

9,2

8,9

9,2

8,9

9,2

Gas Flow

Rate

(m

3

/h)

0,9

4,2

0,9

5,1

1,57

6,7

Fan Speed

(rpm)

1250

5100

1250

6000

1700

6500

Flue Gas

Mass

(g/sec.)

3,7

17,7

3,7

21,6

6,9

28,4

Nozzle

Diameter

(mm)

Model

Q

min.

max.

min.

max.

min.

max.

CO

2

%

8,9

9,4

8,9

9,4

8,9

9,2

Gas Flow

Rate

(m

3

/h)

1,0

4,80

1,0

5,9

1,82

7,8

Fan Speed

(rpm)

1300

5100

1300

6250

1700

6500

Flue Gas

Mass

(g/sec.)

3,7

17,4

3,7

21,3

7

28,4

Nozzle

Diameter

(mm)

Wallcon 42

Wallcon 50

Wallcon 67

G20

7,7

G25

Wallcon 42

Wallcon 50

Wallcon 67

9,5