7

© 2023, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

106R Cabinet Systems User Guide

6190759 (Rev B)

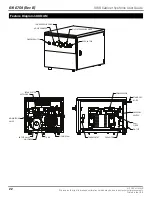

Disassemble the non-return valve and remove the O-ring (1) part

no . 6243000 from the piston .

Clean the non-return valve .

Mount a new O-ring and re-assemble the non-return valve .

Re-install the non-return valve .

h) Check the fans

Check that the fans at the back of the cabinet work . They

will start when the temperature exceeds 30°C and will run

continuously until the temperature falls below 30°C .

i) Check dryer

If a dryer is installed refer to the operating manual for the dryer .

Please note that all service must be carried out by a qualified

person .

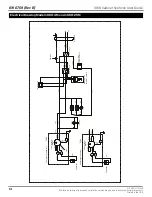

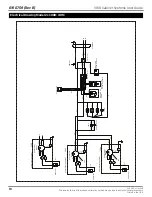

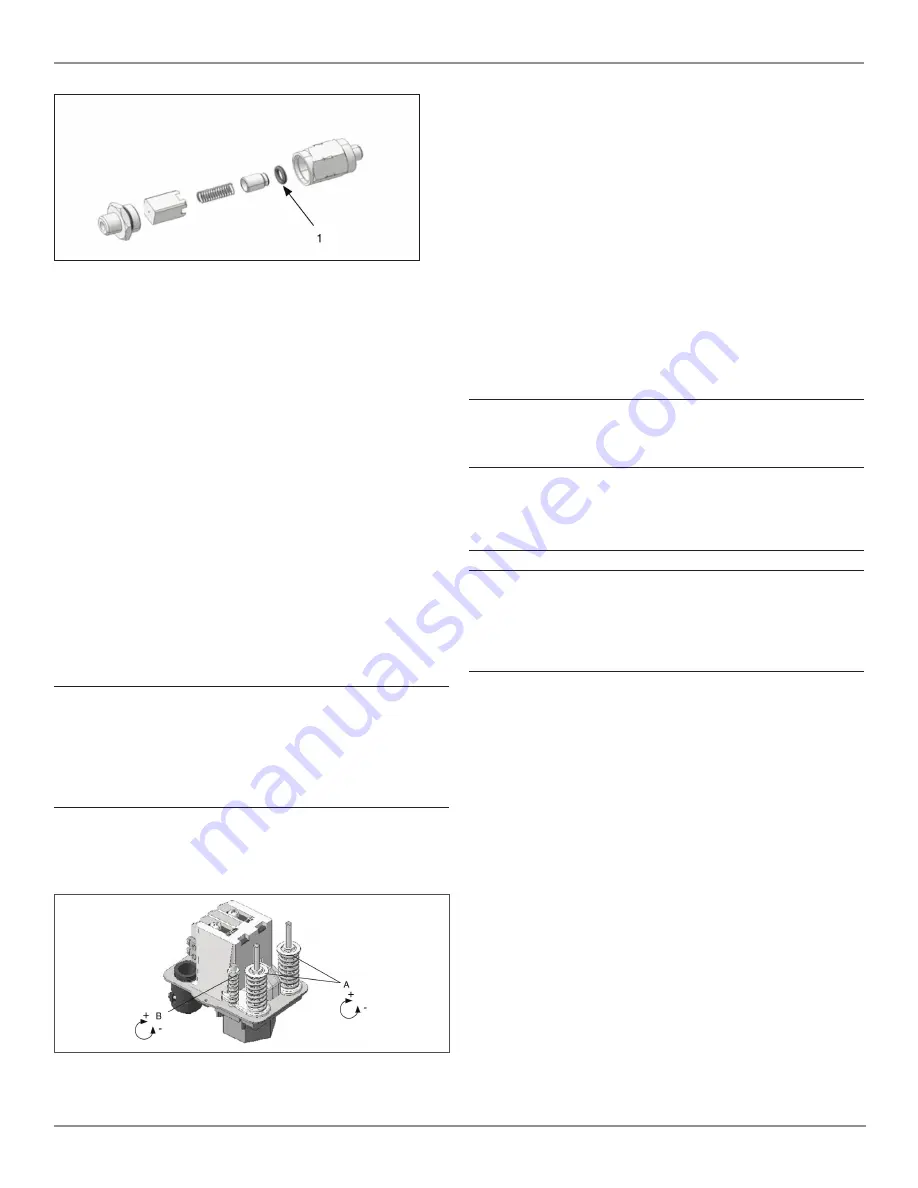

Adjustment of pressure switch

The working presure has ben preset from the factory, and it is

normally not necessary to change this .

However, if it is necessary to change the preset settings, the

instructions mentioned below should be followed carefully .

Warning

The compressor is constructed and approved for a max.

pressure as stated under Technical Specifications - do not

adjust to a higher pressure.

Higher working pressure will reduce the lifetime of the

compressor.

The compressor will stop at max . pressure (stop pressure) and

start again at min . pressure (start pressure) . The difference

between max . and min . pressure is the differens pressure .

Unscrew the lid of the pressure switch . Adjust max . pressure

adjusting the two springs marked A (clockwise: higher pressure) .

Adjust the two springs identically .

Adjust the differens pressure adjusting the spring marked B

(clockwise: higher differens pressure, start pressure maintained) .

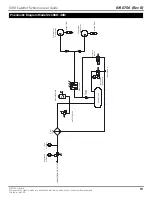

Test of pumping time

The pumping time indicates the condition of the compressor .

1 . Check that there are no leaks in the system .

2 . Empty the air receiver of compressed air so that the

pressure gauge shows 0 bar .

3 . Close the filter regulator and check that the drain valve is

closed .

4 . Start the compressor and note the time it takes until it is

turned off again by the pressure switch . Check that the

pumping time agrees with the technical specifications for

the actual compressor system .

Please note that the pumping time in this manual is given for 0 to

max pressure . Deviations from this result in deviating results .

Important

Always test the pumping time when cold. If the compressor is

warm, the pumping time will be considerably longer.

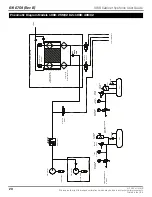

FAULT FINDING AND REPAIR

Important

Switch off and isolate from electrical supply before removing

any parts from the pump. Empty air receiver of air before

performing any operation on the compressors’ pressure

system.

1. Compressor does not start

a . The air receiver is pressurized . The motor will start when

the pressure has dropped to the preset start pressure .

Empty the receiver .

b . Check that the mains supply agrees with the motor

label .

c . No power from mains . Check fuses and plug .

d . Bad connection or broken cable .

e . The motor is overheated and the thermal protection

has switched it off . When cooled the motor will turn on

automatically . Go to section 5 .

f . The compressor has not been unloaded and there

is back pressure on the piston . Ensure that the

compressor is unloaded each time it stops .

g . The motor is blocked .

h . Defective capacitor .

2. The compressor makes a buzzing sound but does not start

a . Leaky non-return valve . Dismount the pressure pipe and

check if air leaks from the non-return valve . Clean and

replace .

b . The motor is blocked .