| 9

en

Grounding

place the grounding clamp directly on the welded part. the touching surface must

be clean and as big as possible - it must be cleaned from paint and rust.

Protective gas and gas tank installation

use inert gases (for example argon, helium or argon-helium mixture) as a protec-

tion gas for tiG welding. make sure that the reduction valve suites the type of the

gas you are using.

Gas tank installation

always properly secure the gas tank in a vertical position in a special holder on

the wall or in the cart. after you finish welding, do not forget to close the gas

tank valve.

the following installation instructions apply for most reduction valve types:

1. step aside and open the gas tank valve (a) for a moment. this way possible dirt

particles are blown off the tank valve.

NOTICE!

Watch for high gas pressure!

2. turn the pressure regulation screw (b) of the reduction valve until you feel the

spring pressure.

3. close the reduction valve.

4. put the reduction valve on the tank over the intake connection seal and tigh-

ten the cap nut (c) with a wrench.

5. install the hose adapter (d) with the cap nut (e) to the gas hose and secure it

with a hose clamp.

6. connect one end of the hose to the reduction valve and the other end to the

welding machine. if the torch had a built-in valve, the hose could be part of the

torch.

7. tighten the cap nut with the hose to the reduction valve.

8. slowly open the tank valve. the tank pressure gauge (f) will show pressure in

the tank.

notice! do not use all the tank’s contents. replace the tank when the pressu-

re drops to approximately 2 bars.

9. open the reduction valve.

10. turn the regulation screw (b) until the flow meter (G) shows the required flow.

notice! When you are setting the gas flow in a machine with a valve equipped

torch, it is necessary to release the valve regulation screw on the torch. close the

tank valve after welding. in case the machine will not be used for a long time,

loosen the pressure regulation screw.

NOTICE!

for machines 220/270/320 mma machines we recommend water-coo-

led torchs (for example ktb 18) combined with independent water cooling (for

instance k5150W).

air-cooled torchs can be used only if maximum load listed by the manufacturer is

adhered to. the manufacturer is not responsible for damages caused by overload

of improperly selected torch.

Panel of functions

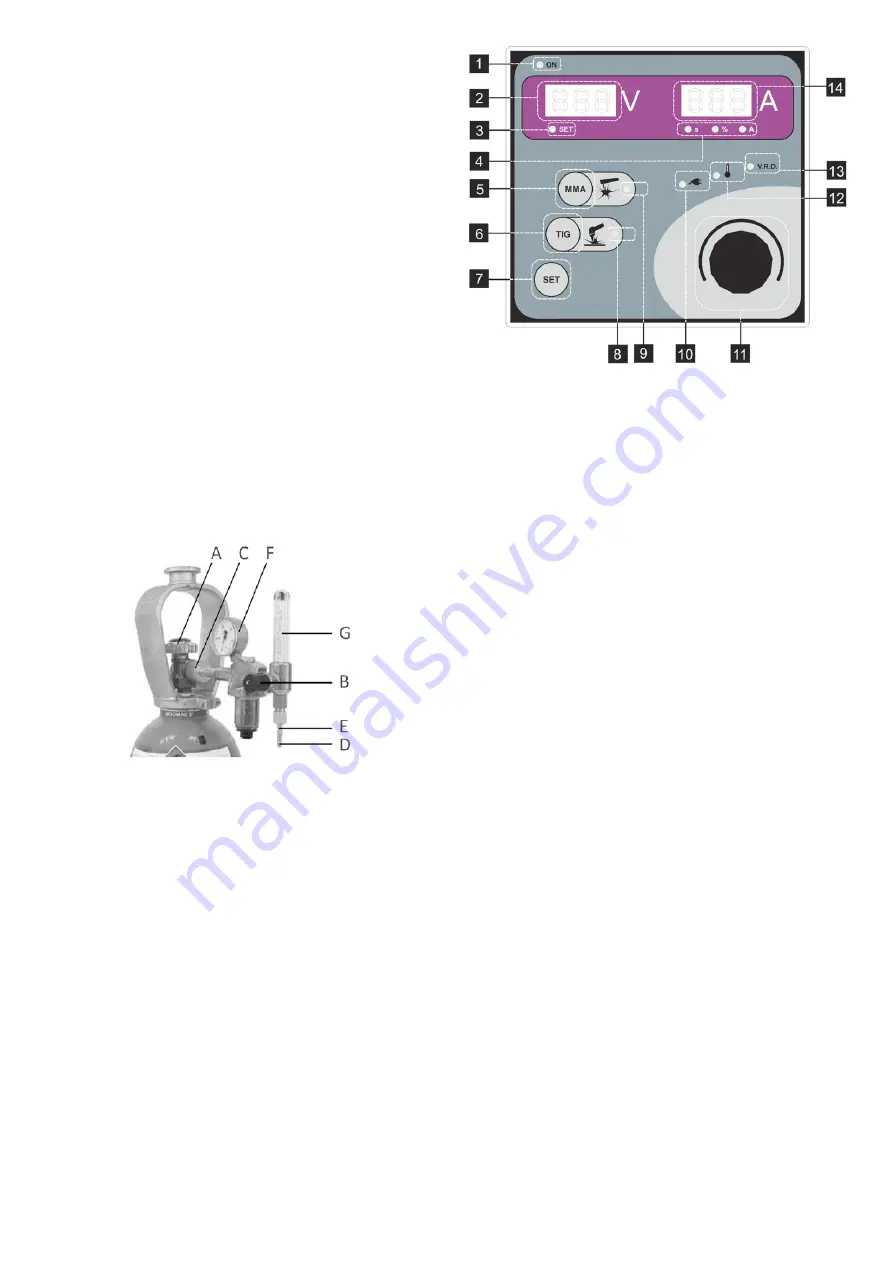

control and signal elements on the digital panel – description of functions:

1.

Inverter control light is on.

the control light is on in case the working part of

the machine is operating.

2.

Voltage/function display.

during welding and 3 seconds after its termination

the display shows the welding voltage value. after welding termination this va-

lue remains on the screen for approximately three seconds. if we are working

in the set mode, abbrevia-tion of the function currently set is displayed.

3.

Parameter setting mode SET control light.

if it is on and display 2 does not

show any function, we can set the value of the welding current. if display 2

shows some function abbreviation, we can set values for that particular func-

tion. during welding it is possible to set only the welding current in both me-

thods. function values cannot be altered during welding.

4.

Control lights showing the display value unit.

5.

MMA method button.

by pushing this button we can choose the mma wel-

ding method.

6.

TIG method button.

by pushing this button we can choose the tiG welding

method.

7.

Function parameter choice button SET.

this button enables entry to the mode

where we can adjust the particular function values. We switch between func-

tions by pushing the set button repeatedly.

8.

TIG method control light.

led indicates tiG method selection.

9.

MMA method control light.

led indicates mma method selection.

10.

Power supply voltage control light.

if the light is on, the voltage is outside the

machine tolerance range.

11.

Welding current and SET values setting selector.

12.

Temperature control light.

led indicates overheating of the machine.

13.

V.R.D. function control light.

during mma method welding led indicates that

v.r.d. function is on. during tiG method welding this led is automatically on.

during welding in both methods this control light will go off, because the vol-

tage on output clamps is not safe.

14.

Welding current/value and status of functions display.

during welding the

welding current value is displayed. after welding termination it remains on for

about 3 seconds. in idle state the value of the welding current is displayed. in

the set mode the state of the selected function or its value is displayed.

Temperature protection

the machines are equipped with protective thermostats on all its performance

parts. in case of overheating (for example as a result of exceeding the maximum

allowed cycle), welding is automatically interrupted and the temperature control

light will go on at the control panel and the display will show „-t-“. after cooling

off the overheating message disappears and the machine is ready for operation.

after welding termination always let the machine cool down. if the machine is

shut off prematurely and turned back on, the ventilator will not start even if the

machine is not completely cooled off.

Remote control

Welding current regulation remote control can be attached to the welding ma-

chine. the a3 connector located at the front side serves for the remote control

connection. the remote control is functional in both the mma and tiG methods.

the remote control connector connection is described in the chapter “drawings”.

it can be used only with remote control equipped with 10 kΩ potentiometer.

MMA welding method

notice! the machine is equipped with functions, which make it easier to weld

with the mma method. these functions make it possible for inexperienced wel-

ders to achieve high quality welds even without previous welding experience.