12 | en

position s (pf)

10

- 30°

20 - 30°

10 – 30°

15 – 40°

Preparation of basic material:

in table 7 there are given values for preparing material. sizes shall be determined

according to picture:

a

s

α

d

table 7

s (mm)

a (mm)

d (mm)

α (°)

0 - 3

0

0

0

3

0

0.5 (max)

0

4 - 6

1 - 1.5

1 - 2

60

Welding in TIG method

a) With the machine disconnected from power supply connect the electrode

holder and grounding cable to clamps 1 and 2.

b) connect the gas line from the welding torch, which must be equipped with a

valve, to the argon gas tank through a reduction valve. turn the gas on with the

valve on the gas tank.

c) connect the machine to power supply.

d) turn on the main switch (5).

e) Wait for the welding machine test to finish – all control lights and displays will

be on for several seconds.

f) push met button to switch the machine to the tiG-la method with touch

ignition or push it again for touch-less ignition.

g) set the welding current. set the desired value of the welding current with the

rotating selector. the value will show on display. at the same time the control

light in field (2) will be on showing the ampere value.

h) by pushing the button set (10) on the control panel we can switch between

individual functions. by rotating selector we can set values.

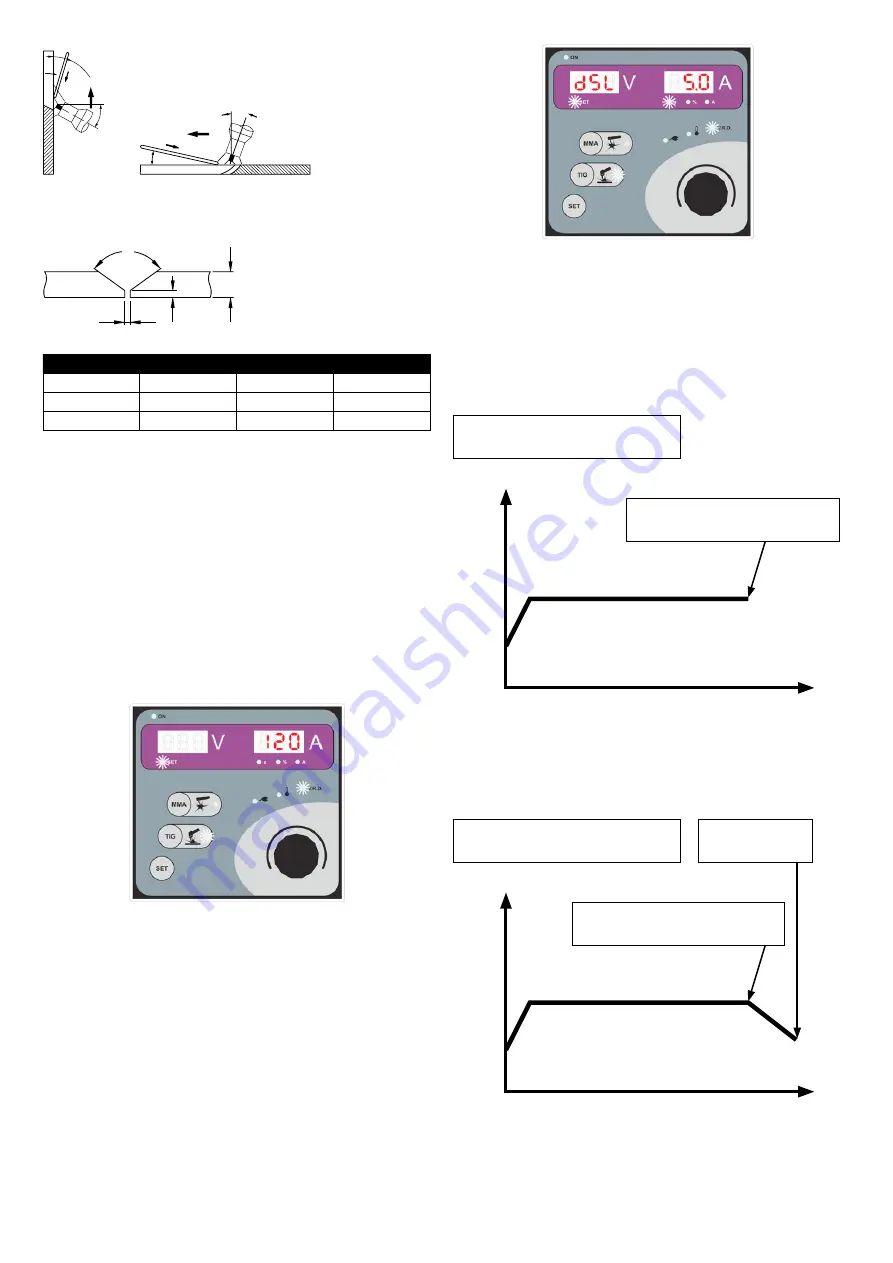

DOWN-SLOPE function

run down time from the set welding current to the end current.

push the set (7) button, the display (2) will show the dsl sign. With the rotating

selector (11) choose the desired value (off, 0.1 s up to 10 s). the status or the

value will be shown on the display (14). at the same time the control light in field

4 will inform you that the value is in seconds.

Arc ignition in TIG method

turn the gas on with the valve on the gas tank. touch the welded material with the

electrode and remove it. the welding arc will ignite.

Welding process termination in the TIG method

When the doWn-slope function is set to the off position, the welding process

will be terminated by removing the welding electrode from the material (the

welding arc interruption).

Function DOWN/SLOPE OFF

touching of the material with the electrode

and removing the electrode - arc ignition

removing the electrode - arc extinction

i (a)

t (s)

Welding current (e.g. 90 a)

When the doWn-slope function is set to a time value (0.1 – 10 s), the welding

process is terminated by a short removal of the welding electrode from the

material about 10 mm and subsequent approach. after that the welding current

starts to drop according to the time set in doWn-slope until full arc extinction.

Funktion DOWN/SLOPE (0.1 – 10 s)

touching of the material with the electrode

and removing the electrode - arc ignition

removing and subsequent coming near

with the electrode

automatic arc

extinction

i (a)

t (s)

Welding current (e.g. 90 a)

Error message display

during machine operation some errors and break-downs may appear which will

be announced by an -err- sign and error code. the following ones are important

for the user: