62

|

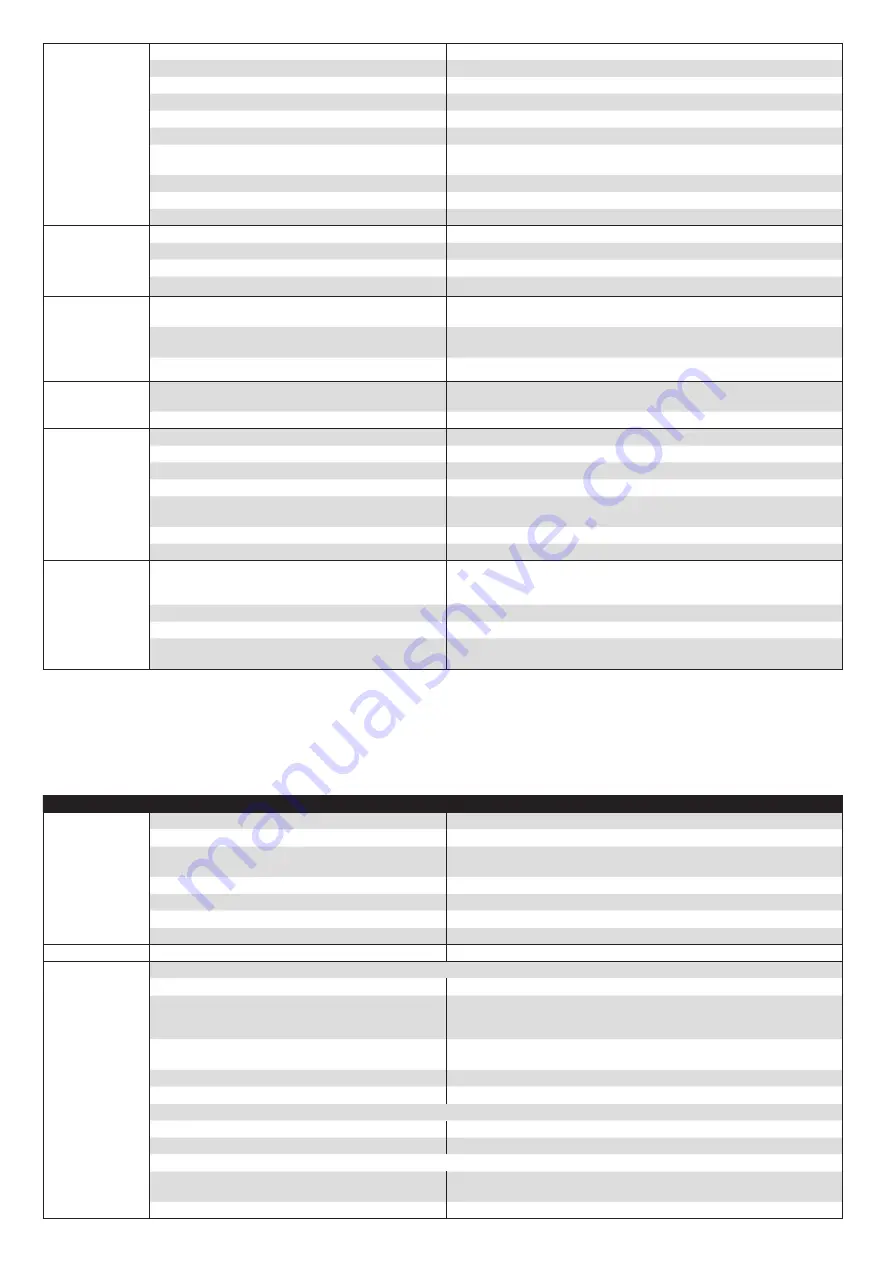

DE - Handbuch für die Störungsbeseitigung

Hinweis: Die Maschine können nur qualifizierte und entsprechend geschulte Mitarbeiter reparieren!

Defekt, Anzeichen

Grund

Lösung

Ventilator läuft nicht

Schweißmaschine

schweißt nicht.

1/ Ist die Maschine an das Netz geschaltet?

Maschine an das Netz schalten.

2/ Gibt es in der Steckdose Spannung?

Netzsteckdose überprüfen.

3/Ausgefallenes Draht aus der Klemmleiste des Steckers oder

Steckdose?

Netzstecker oder -dose überprüfen.

4/ Hauptschalter ist beschädigt.

Hauptschalter austauschen.

5/ Ausgefallenes Kabel aus der Klemmleiste in der Maschine.

Kabel befestigen.

6/ Kleines Trafo bleibt ohne Spannung - Phase ausgefallen.

Steckdose, Stecker und Netzzuleitungskabel überprüfen.

7/ Steuerungstrafo defekt.

Steuerungstrafo austauschen.

Ventilator läuft nicht. Ventilator defekt.

Ventilator austauschen.

Ventilator läuft,

Schweißmaschine

schweißt nicht.

A/ SCHÜTZ SCHALTET NICHT - VORSCHUB FUNKTIONIERT NICHT

1/ Steuerungsstecker des Brenners nicht angeschlossen.

Steuerungsstecker des Brenners anschließen.

2/Schalter oder Steuerungskabel im Brenner defekt.

Brenner frei schalten, zwei Kontakte für die Steuerung überbrücken Falls alle

Maschinenfunktionen in Ordnung sind, den Schalter, das Koaxialkabel oder den

ganzen Brenner austauschen.

3/ Am Kleintrafo keine Spannung - eine Phase ausgefallen.

Netzsicherung austauschen, Steckdose, Stecker und Zuleitungsnetzkabel überprüfen,

Phasen am Schütz kontrollieren.

4/ Schütz - Spule defekt.

Schütz austauschen.

5/ Thermostaten defekt (siehe Schema).

Thermostaten austauschen.

B/ SCHÜTZ SCHALTET - VORSCHUB FUNKTIONIERT NICHT

1/Steuerungselektronik defekt.

Platte austauschen.

2/Vorschubmotor defekt - Kohlenstifte.

Vorschub - Kohlenstifte austauschen.

B/ SCHÜTZ SCHALTET, VORSCHUB FUNKTIONIERT

1/ Erdungskabel gebrochen.

Die Isolierung muss nicht beschädigt sein - es ist nicht sichtbar - das Erdungskabel

austauschen.

2/ Koaxialkabel des Brenners defekt.

Koaxialkabel austauschen.

The wire

is unregularly fed.

1/ Worn out sheave - the wire is slipping.

Change the sheave.

2/ Appropriate diameter of the sheave has not been used.

Change the sheave.

3/ Faulty motor - worn-out carbons or faulty retch.

Change the carbons, the retch or the whole motor.

4/ Rubbed-in upper sheave.

Change the upper pulley.

5/ The spring of the appropriate diameter has not been used. Change the spring.

6/ Dirty spring.

Clean the spring - the spring has to be cleaned every week.

7/ Thrust on the shift is too tight - the wire is being missha

-

pen.

Release the thrust of the shift sheave.

8/ Sheave for some other diameter of the wire.

Clap on the sheave which corresponds to the used diameter of the wire.

9/ Sheave of the feed is worn out.

Replace the sheave with a new one.

10 The spool of the wire is being too intensely braked.

Release the spool brake.

The el. transformer

is making very

strong grumbling

noise, warming up

and scorching.

1/ Damaged alteration switch of the currency.

Change the alteration switch.

2/ Damaged secondary rolling of the transformer.

Change the transformer.

3/ Damaged primary rolling of the transformer.

Change the transformer.

4/ Short circuit on the rectifier or the efferent.

Remove the cause of the short circuit.

Welding wire is red

-

-hot in the welding

torch, on the sheave

of the feed and the

power cable is being

warmed up.

1/ The spool or the wire is touching the machine case.

Flatten the misshapen parts of the spool in order that they do not touch the

machine case.

2/ Metal dirt connect the body of the feed with the case of

the welding machine.

Clean the space of the feed from all dirt.

3/ The rectifier is touching the case of the machine.

Avoid the contact of the body of the rectifier and the case of the machine.

Gas does not go

through the welding

machine.

1/ Clogged gas hose in the welding torch.

Make sure if the right inner diameter of the spring has been used, try to clap on

a different welding torch or change coaxial cable or the whole welding torch.

2/ The valve is without voltage.

Change the panel of controlling electronics.

Porous welding

point.

1/ Gas is not on or the compressed gas cylinder is empty.

Turn gas on or connect a new full compressed gas cylinder.

2/ Too strong draught in the working place.

Increase the flow of the shielding/protective gas or avoid draught.

3/ Material is destroyed by rust, paint or oil.

Purify the material well.

4/ The orifice of the drawing die is dirty from the spatter.

Remove the spatter and spray the orifice with separating spray.

5/ The welding torch is too far from the material.

Hold the welding torch from the material in such a distance which equals 10 times

bigger than the diameter of used welding wire.

6/ Too small or too big flow of the gas.

Adjust the flow of the gas on the appropriate values.

7/ Hose connections do not seal.

Check if all hose connections seal.

Welding wire forms

a loop between

the sheaves and

the opening of the

capillary of the

welding torch.

1/ The opening of drawing die (point of the welding torch) is

too narrow, does not correspond to the diameter of the used

welding wire.

Change the drawing die and use the right one.

2/ Pressure on the flattening sheave is too big.

Release the flattening sheave of the feed.

3/ Dirty or damaged spring in the welding torch.

Clean the spring - the spring has to be cleaned every week or change it.

4/ The spring in the welding torch is suitable for some other

diameter of the welding wire.

Change the drawing die for a suitable one.

Summary of Contents for 305

Page 22: ... 67 ...