24

|

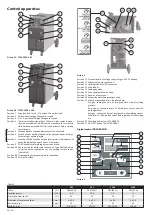

Picture 5

WARNING!

During wire threading don’t aim the torch against eyes!

Changes when useing aluminium wire

For welding with aluminium wire it is necessary to use a special roll with „U“

profile (chapter “Spare parts of wire feed”). In order to avoid problems with

„ruffle“ of wire, it is necessary to use wire in diameter min. 1.0 mm from

alloys AIMg3 or AIMg5. Wires from alloys A199.5 or AlSi5 are too soft and

can easily cause problems with feed. For welding of aluminium it is nece

-

ssary to equip the torch with teflone bovden and special flow drawing tie. As

shielding atmosphere it is necessary to use pure Argon.

Adjustment of gas flow

Electric arc and welding pool must be perfectly protected by gas. Too little

amount of gas cannot create necessary shielding atmosphere and on the

contrary, too big amount of gas entrains air into electric arc, which makes

the weld imperfectly protected.

Proceed as follows:

• fix the gas tube with the filter on the inlet of the gas valve on the back side

of the machine (pic. 2, pos. 18)

• if you use gas carbon dioxide, it is suitable to plug in gas heating (during

the flow less than 6 litres/min the heating is not necessary)

• plug in the cable of heating into the socket (pic. 2, pos. 11) on the machi

-

ne and into the connector at cylinder pressure regulator, polarity is not

important

• press GAS TEST button - for STANDARD from the rear of the machine (pic.

2, pos. 21), for PROC./SYN. on the control panel. Turn adjustment screw

on the bottom side of pressure valve until flow indicator shows required

flow, then release the button

• if the machine was not used for a longer time, or after entire change of

welding torch, it is recommended to blow ways by fresh gas before you

start welding

Adjustment of welding parameters

Adjusted parameters depend on used protective gas, wire diameter, applied

wire type, size and position of a weld etc.

Reference setting of wire speed and switch positions can be found in pages

50 - 53.

Machines STANDARD

Adjustment of main welding parameters of welding voltage and speed of

wire shift is carried out with a potentiometer of wire speed (pic. 1A/B, pos.

5) and a voltage switch (pic. 1A/B, pos. 2, 3). You shall always allocate speed

of wire shift to adjusted voltage (switch position 1-20/1-40).

2

1

3

1 - Both potentiometers switched off - function switched off, normal welding

2 - Left Potentiometer Active / Right Off - Set the spot time

3 - Both potentiometers active - set the pulse time

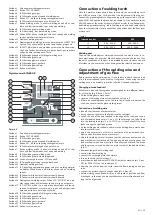

Machines PROCESSOR/SYNERGIC

Setting of main welding parameters of welding voltage and wire feed speed

by a potentiometer (pic. 3, 4, pos. 1) and a voltage switch (pic. 1A/B, pos.

2, 3). The wire speed is always assigned to the set voltage (switch position

1-20/1-40).

Setting speed of wire shift

Press button SET until you switch on LED marked in the picture.

Use the potentiometer to set up required value of shift speed within range

1-20 m/min

NOTE 1:

Speed of wire shift can also be adjusted and changed during wel

-

ding. Either a potentiometer or a remote control UP/DOWN can be used.

During welding (turning the potentiometer).

NOTE 2:

Bottom display shows speed of wire shift only if red LED SETTING

and LED “m/min” are on.

Adjustment of other welding parameters

Controlling electronics of machines PROCESSOR and SYNERGIC enables ad

-

justment of the following welding parameters:

• Time duration of pre-gas (time of protective gas blow before the begi

-

nning of welding process).

• Time of start of wire shift speed - function SOFT START (time of start from

minimum shift speed up to value of adjusted welding wire speed, only

PROCESSOR).

• Approaching wire speed (table 4).

• Speed of wire shift m/min (speed of wire shift during welding).

• Time of switching off interval of welding voltage on arc opposite wire

shift: „burning out“ of wire towards the torch top.

• Time of post-gas after finishing welding process.

Table 4 - Range of value settings -

Machines PROCESSOR and SYNERGIC

the duration

of the pre-gas

approach

speed

wire feed rate

rise time

wire feed

speed

point time

lag time

burn out

post-gas time

(s)

(m/min)

(s)

(m/min)

(s)

(s)

(s)

(s)

PROCESSOR

305, 405, 3500, 4100

0 - 3

-

0 - 5

1 - 20

0.5 - 5

0.2 - 2

0.0 - 0.99

0.1 - 10

SYNERGIC

305, 405

0 - 3

0.5 - 20

-

1 - 20

0.5 - 5

0,2 - 2

0.0 - 0.99

0.1 - 10

EN

Summary of Contents for 305

Page 22: ... 67 ...