|

27

Press button SET until you switch on LED diode marked in picture.

Use the potentiometer, thus you shall choose wire diameter SG2 you are

going to use - 0.6 - 0.8 - 1.0 mm.

Approximate thickness of material possible to weld according to current ad

-

justment will be shown on upper display. Currently adjusted speed of wire

shift will be shown on bottom display, which is changed automatically when

you change positions of voltage switch. Fall or rise in welding capacity is

adjustted with a voltage switch.

Switching function SYNERGIC off

Press button SYN. Diode SYN and material thickness will switch off.

Function SYNERGIC is off.

NOTE 1:

Shown values of material thickness are only approximate. Thickness

of material can vary according to welding position etc.

NOTE 2:

To correct parameter for wire shift, you shall use a potentiometer

or buttons of remote control UP/DOWN.

NOTE 3:

Parameters of the program synergic function are designed for

copper coated wire SG2. In order to reach the correct function of the sy

-

nergic programs, it is necessary to use quality wire, protective wire, gas and

welding material.

NOTE 4:

In order to reach the correct function of the synergic machine it is

necessary to keep prescribed diameters of cables to wire diameters and the

right die otherwise the correct function of the machine is not guaranteed.

Further on, it is necessary to secure quality power supply – 400 V, max. ± 5%,

connecting to ground of the welding material (use an earthing clip directly

on the welding material).

Recorging own parameters of the speed of the wire shift into

memory

The function of storing parameters is on only if the function synergic is on.

1. Choose the required speed of the wire shift.

2. Press and hold the button SYN and then.

Keep together

3. Release both the buttons - new parameters are stored.

All the required parameters can be stored and rewritten in this way as nece

-

ssary. The recorded parameter is adjusted always in the same position of the

voltage switch when the parameter was stored.

Return to the factory default settings

A return to original parameters SYNERGIC adjusted by the producer is done

by the follow-up pressing and holding the button SYN and then pressing and

releasing the button of wire threading. In such a way it is possible to return

single parameters which have been stored. A total return of all the pre-ad

-

justed values to the values set up by the producer can be done through the

function factory configuration.

Keep together

Function LOGIC

(only with machines PROCESSOR and SYNERGIC)

Function LOGIC includes a file of simplifying and clarifying points which pre

-

sent adjusted and currently set values.

If two displays show a few different parameters, it is necessary to simplify

presentation of parameters. Function LOGIC operates just in this way - it

makes everything clear and distinct:

• Upper display switches on during welding process only when electronics

makes measurements and shows welding current A (in case there is no

mode SYNERGIC on. In case there is mode SYNERGIC on display is lit up

constantly and only shown values change). After approx. 7 sec. display

switches off automatically again. Thus electronics increases orientation

while reading parameters during adjustment.

• Upper display shows only welding current. When function SYNERGIC is

on (only with machines Synergic), upper display shows thickness of mate

-

rial.

• Bottom display shows welding voltage while welding and other values -

time, speed etc. during adjustment.

• LED SETTING will switch off during welding process only when a digital

voltampermeter is used.

• LED SETTING is on during welding only when operating staff is adjusting

and changing speed of wire shift with a potentiometer or a remote con

-

trol UP/DOWN. As soon as operating staff stops adjustment of a para

-

meter, LED SETTING will be switched off automatically within 3 sec. and

display shows value of welding voltage.

Recommended adjustment of welding parameters see charts on pg. 50 - 53.

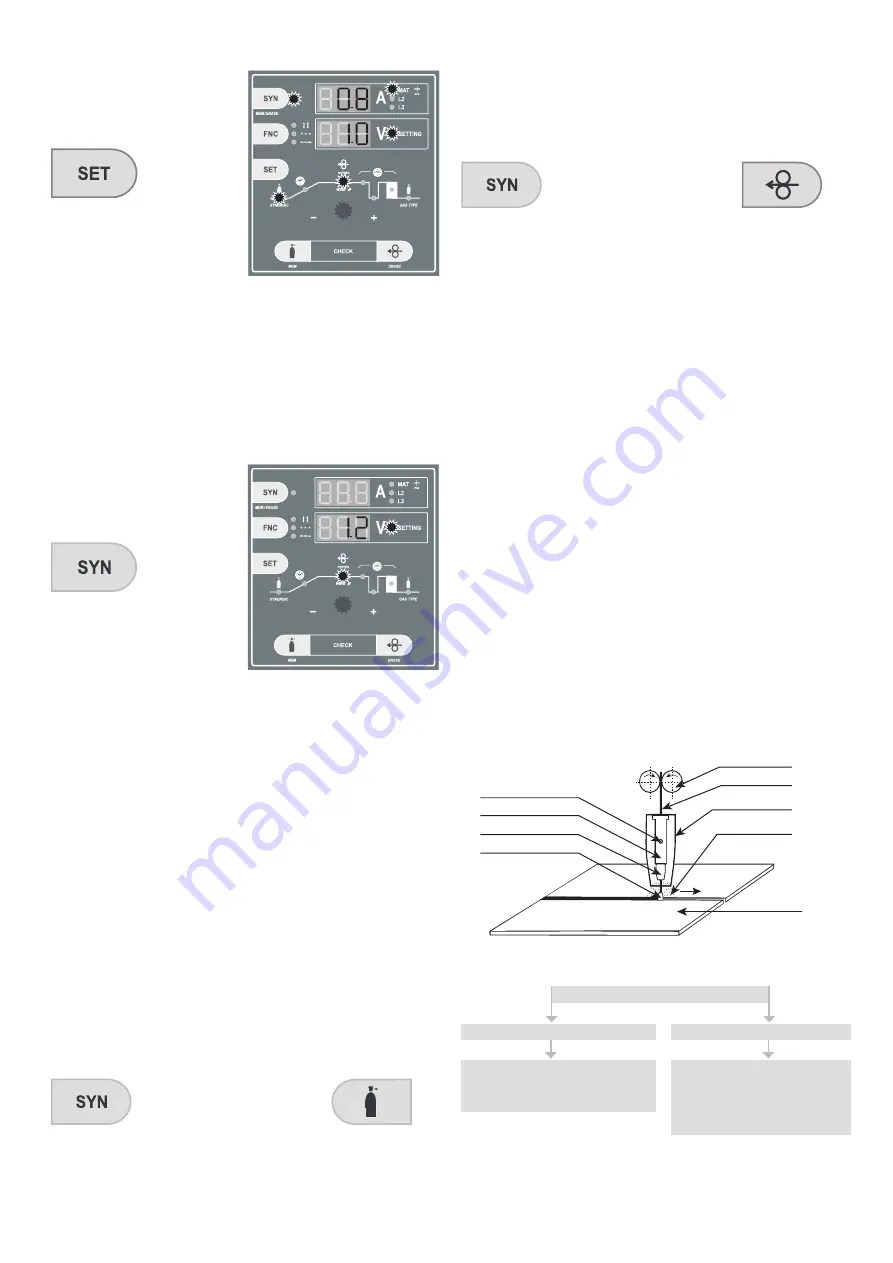

Principle of MIG/MAG welding

Welding wire is lead from the roller into the flow drawing tie with the use of

the feed. Arc joins thawing wire electrode with welding material. Welding

wire functions as a carrier of the arc and as the source of additional material

at the same time. Protective gas flows from the spacer which protects arc

and the whole weld against the effects of surrounding atmosphere (pic. 6).

Gas opening

Tip holder

Welding tip

Welding arc

Wire feeder rolls

Welding wire

Nas nosle

Protection gas

Welding

piece

Picture 6

Protection gases

Protective gases

Inert gases - MIG method

Active gases - MIG method

Argon (Ar)

Helium (He)

Mixtures of He/Ar

Carbon dioxide

Mixed gases

Ar/CO

2

Ar/O

2

EN

Summary of Contents for 305

Page 22: ... 67 ...