BAYKAN ISI SIST.SAN.TIC.AS

.

- 10 -

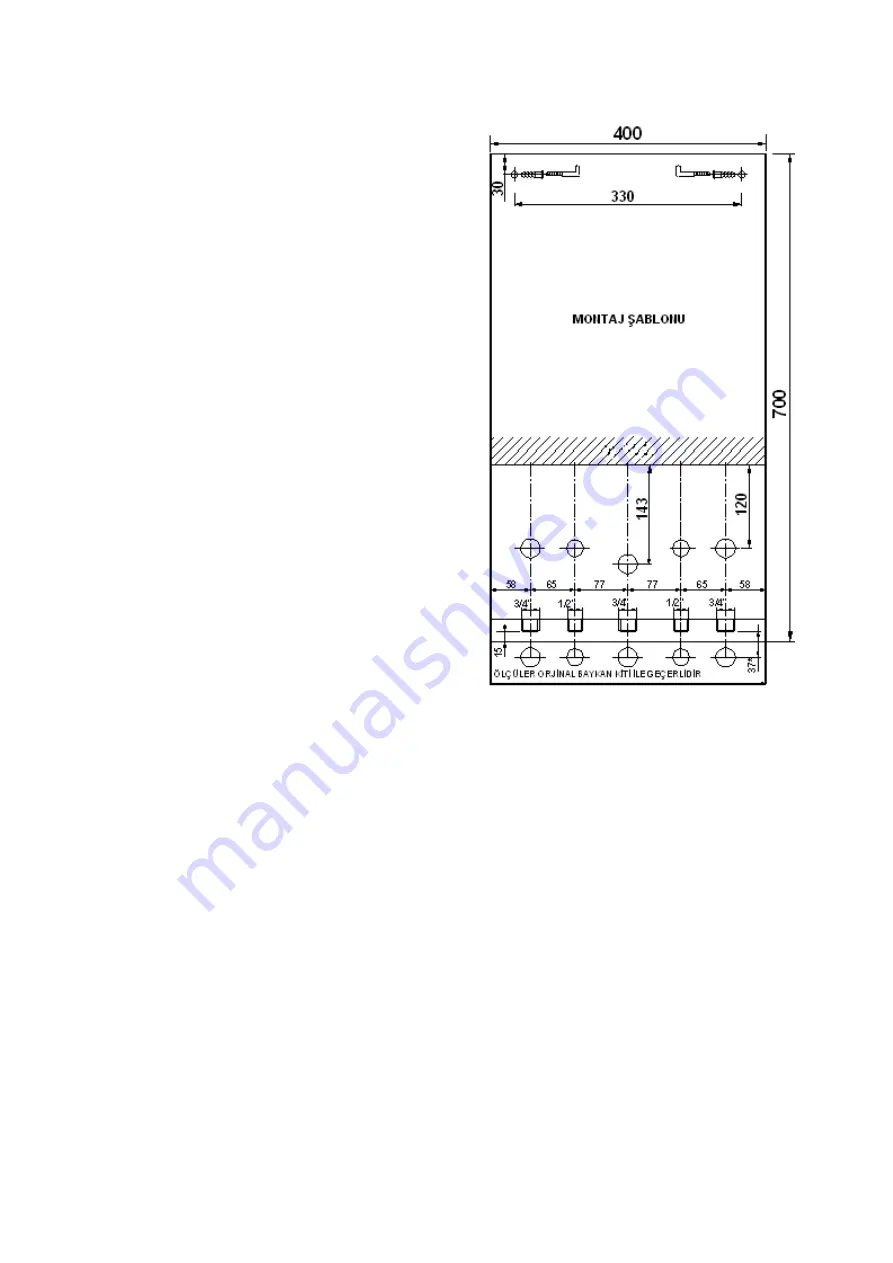

2. PLACEMENT OF THE WALL HUNG BOILER

2.1 MOUNTING THE WALL HUNG BOILER

TO THE WALL

Considering the dimensions of your device

and by using the installing and mounting

diagram on the packages, determine the

positions of wall screws and sign them.

NOTE: You should leave a space of at least

40 cm. under the device while mounting

your boiler to the wall.

Determine the positions of connecting

parts by using the assembly figure.. Fig.6

Place the hanging screws in their positions

according to the measurements given in

the figure.

Hang your wall hung boiler to hanging

screws.

2.2 WATER AND GAS CONNECTIONS

Before starting the procedures related with water

connections, we recommend you to wash the

installation in order to get rid of the particles that may

be present in pipes and radiators.

Connect

the

water

and

gas

according

to

the positions shown in the figure.

Connect the outlet of safety valve to the

waste water line by means of a hose.

(Otherwise, the manufacturer of the wall hung

boiler shall not be liable for the cases that arise

due to the intermeddling of the safety valve. )

Place a valve to the inlet of each of water

and gas pipe lines.

Ensure that the pressure of domestic

water is 1-6 bars. If the water pressure is

higher than 6 bars, use pressure set up

valve.

A dirt collector must be connected to the

water entries.

fi

ek.6

Perform the followings for a good gas connection.

Ensure that the Gas pipe is clean, clean around it.

The building internal gas distribution pipe must conform to the technical specifications and

regulations.

An

elastic

connection

between

the device and internal gas line of the building must be

made. (3/4”).

The proper sealed and hermetic gaskets must be used for spacing connection.

Inspect and compare the gas inlet pressure values and the gas inlet values of the building.

These adjustments are only performed by Baykan Service Headquarters and Baykan

authorized personnel.

Do not forget to let the air in the gas pipe out.

NOTE: When the conversion from natural gas to L.P.G. is being performed, the burner jets

suitable for L.P.G. must be changed. The gas inlet pressure should not exceed 60mbars.