www.gastron.com

14

_

15

■ Stabilization time of 30 min from the initial supply of operation power to the sensor for the stabilization of the sensor.

Calibration and test must be performed approx. 30 min after when the sensor has been stabilized.

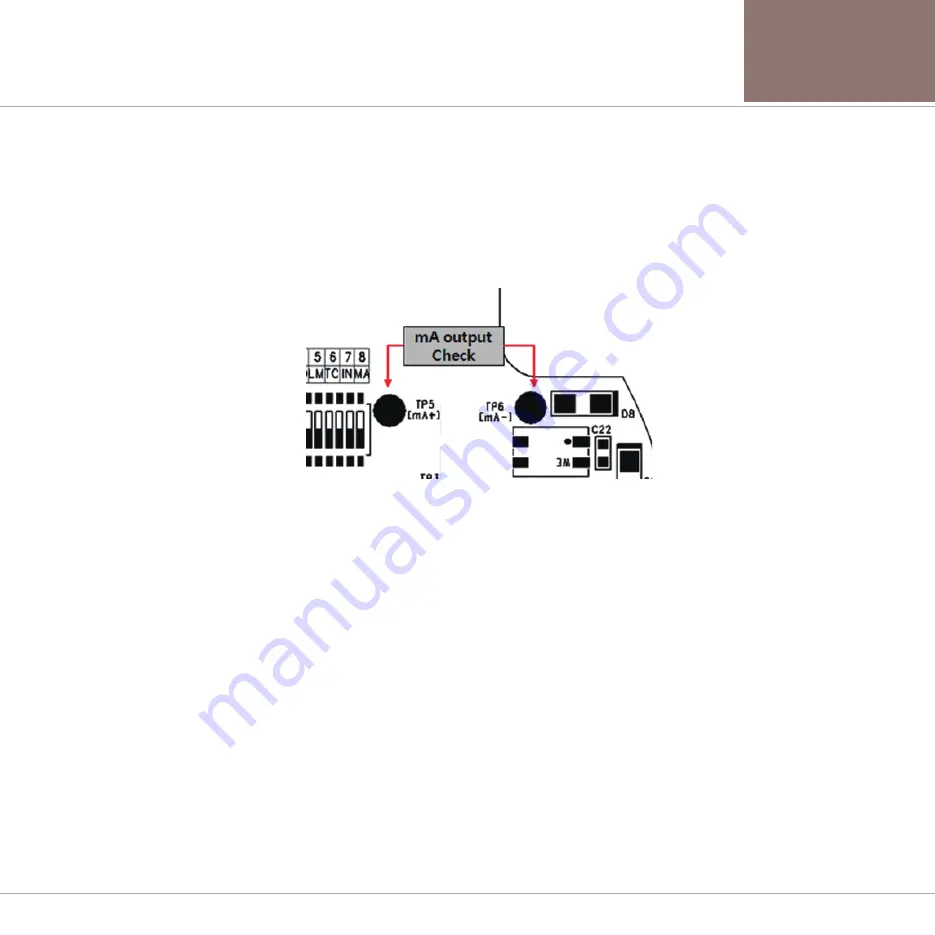

6.1. 4-20mA Output Diagnosis

■ It supplies voltage of 18~31 V and current of 200 mA to the sensor. When the voltage is measured by connecting a

multimeter to TP5 (+mA) and TP6 (-mA) of AMP PCB, current of 4~20 mA can be confirmed.

6.2. 4mA Adjustment (ZERO Calibration)

■ Check voltage of 18~31 V DC at both (+24 V) and (GND) of terminal block 'CN5'.

■ Check whether (mA) terminal of terminal block 'CN5' is connected to the receiver.

■ Change DMM to current measuring mode, then connect (+) and (-) terminals of DMM to TP5 (+mA) and TP6(-mA) of

AMP PCB, respectively.

■ When zero switch (SW5) is pressed for 3 sec, a message "[ZE][RO]" flashes 3 times on FND1 and FND2 and it enters

zero calibration mode.

■ When clean air or 99.9% nitrogen (N2) is injected to cell part, 4 mA output is observed. If the output is not 4 mA, adjust

the potentiometer 'VR2 (ZERO)' left and right to set 4mA.

■ Adjust 'ZERO' potentiometer to obtain a current of 4.00 mA to be displayed on FND1 and FND2.

■ When zero switch (SW5) is pressed for 3 sec after output is set to 4 mA, result from zero calibration is displayed on

FND1 and FND2. "[PA][SS]" means that the calibration has performed successfully. "[FA][IL]" means that the calibration

has not met the condition and failed. In this case, sensor and power must be reconfirmed then calibration shall be

performed again.

6. Calibration and Maintenance

[Figure 8. 4-20mA Output Test Terminal]