Operation

16

Dimple Grinder User’s Guide

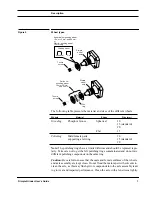

Figure 8

Set grinding by dimple depth.

11. The AutoTerminator may now be switched on (

A

UTO

button).

When the Dial Indicator is within 2-3 µm of zero, the Autoterminator will

automatically switch off the specimen turntable and grinding wheel motors.

Grinding of the remaining 2-3 µm may be done with reduced load and

grinding speed.

Note: A small pocket of dilute paste should be present on the specimen at all

times and the specimen surface and grinding wheel must not be permitted to dry

out. Also, it is recommended the wheel and specimen be occasionally cleaned

and fresh diamond compound applied.

4.6 Set Grinding by Final Thickness

Another method of dimpling is to set grinding by final thickness.

To set grinding by final thickness

1. Set the Counterweight load (20 g) and select a mid-range grinding

wheel speed.

0.000

0.100

0

Zero

stop

Analog dial

indicator

Grinding

wheel

Spring loaded

stylus

Digital

display

Specimen

mount

with

specimen

Micrometer head raised.

Digital display zeroed.

Micrometer head

lowered 100

µ

m

Material to be removed,

100

µ

m (dimple depth)

100

µ

m

Summary of Contents for 656

Page 2: ...Part Number 656 82002...

Page 6: ...iv Dimple Grinder User s Guide...

Page 10: ...viii Dimple Grinder User s Guide...

Page 42: ...Spares and Consumables 32 Dimple Grinder User s Guide...

Page 44: ...I 2 Dimple Grinder User s Guide...

Page 48: ......