Operation

Dimple Grinder User’s Guide

17

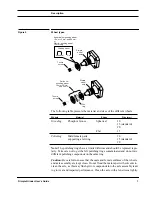

2. Check both motors (

T

ABLE

and

A

RM

buttons on Control Panel) are off.

3. Lower the Micrometer Drive end face (clockwise).

4. Place centering ring and the specimen mount, without specimen, on the

Magnetic Table.

Carefully lower the grinding wheel (use the Cam) onto the specimen mount.

5. Raise the Micrometer Drive until the dial indicator needle has rotated

one complete turn and just reaches zero.

Note: Take care not to raise the Micrometer Drive past zero.

6. Press the

Z

ERO

button to zero the Dimple Depth digital display.

This setting may be used for any number of specimens.

7. Carefully raise the Platform.

Remove the specimen mount and replace it with one having a specimen

attached.

8. Raise the micrometer end face (rotate Drive counter clockwise) until

the display shows the required final thickness.

The reading on the digital display will be negative.

9. Use the Cam and carefully lower the grinding wheel onto the specimen.

The Dial Indicator now displays the thickness of material to be removed.

This value plus the digital display reading represent the combined thickness

of the specimen plus the thickness of the mounting wax.

10. Place a small amount of diamond compound onto the wheel and the

specimen.

Use a toothpick for the compound and then moisten with distilled water.

11. Turn on both motors.

12. The AutoTerminator may now be switched on (

A

UTO

button).

When the Dial Indicator is within 2-3 µm of zero, the Autoterminator will

automatically switch off the specimen turntable and grinding wheel motors.

Grinding of the remaining 2-3 µm may be done with reduced load and

grinding speed.

Note: A small pocket of dilute paste should be present on the specimen at all

times and the specimen surface and grinding wheel must not be permitted to dry

out. Also it is recommended the wheel and specimen be occasionally cleaned

and fresh diamond compound applied.

Summary of Contents for 656

Page 2: ...Part Number 656 82002...

Page 6: ...iv Dimple Grinder User s Guide...

Page 10: ...viii Dimple Grinder User s Guide...

Page 42: ...Spares and Consumables 32 Dimple Grinder User s Guide...

Page 44: ...I 2 Dimple Grinder User s Guide...

Page 48: ......