Operation

20

Dimple Grinder User’s Guide

microscope. The exact time needed to polish the specimen will vary depending

on hardness.

4.8 Polishing to Final Thickness < 20 µm

Producing a dimpled area of < 20 µm thickness requires extended polishing

with the felt wheel. The specimen has to be first coarsely polished and finished

with a fine polish. The micrometer is not used because the softness of the felt

makes it impossible to obtain an accurate reading.

Dimpling progress can be easily monitored for specimens on glass mounts

when viewed in transmitted light on the microscope. In the case of semiconduc-

tors, the color of the specimen as seen with transmitted light is closely related to

thickness. For silicon, red indicates a thickness of about 10 µm while yellow

indicates a thickness around 5 µm for (100) orientation.

4.8.1 Coarse Polishing

When a specimen thickness of 15-20 µm has been reached by grinding, the

specimen is thoroughly cleaned and the grinding wheel replaced with a felt pol-

ishing wheel. The object of the coarse polishing stage is to remove the scratches

and other mechanical damage resulting from grinding and to produce a specular

surface.

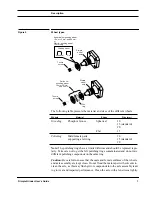

To coarse polish

•

Set the Counterweight to 20 g and the wheel speed to mid range.

•

Use a 2–4 µm diamond compound on the specimen and the wheel.

Silicon normally requires coarse polishing for about 5 minutes. This time

should be split into short periods interspersed by cleaning of the specimen and

wheel with a cotton swab and distilled water followed by acetone or other sol-

vents.

4.8.2 Fine Polishing

The object of the fine polishing stage is to very gently reduce the specimen

thickness to less than 2 µm. The specimen must be completely cleaned of all

traces of the previous polishing compound. Lack of care in accomplishing this

will make it impossible to thin the specimen as required.

To fine polish

•

Mount a new, clean felt polishing wheel.

•

Set the Counterweight to 20 g and the wheel speed to mid range.

Summary of Contents for 656

Page 2: ...Part Number 656 82002...

Page 6: ...iv Dimple Grinder User s Guide...

Page 10: ...viii Dimple Grinder User s Guide...

Page 42: ...Spares and Consumables 32 Dimple Grinder User s Guide...

Page 44: ...I 2 Dimple Grinder User s Guide...

Page 48: ......