PIPS II O

Owners Man

Fi

Th

va

m

ion

To

(R

op

1.

th

µm

2.

20

ab

ce

3.

8 µ

4.

ab

m

NO

co

Pl

an

nual and Use

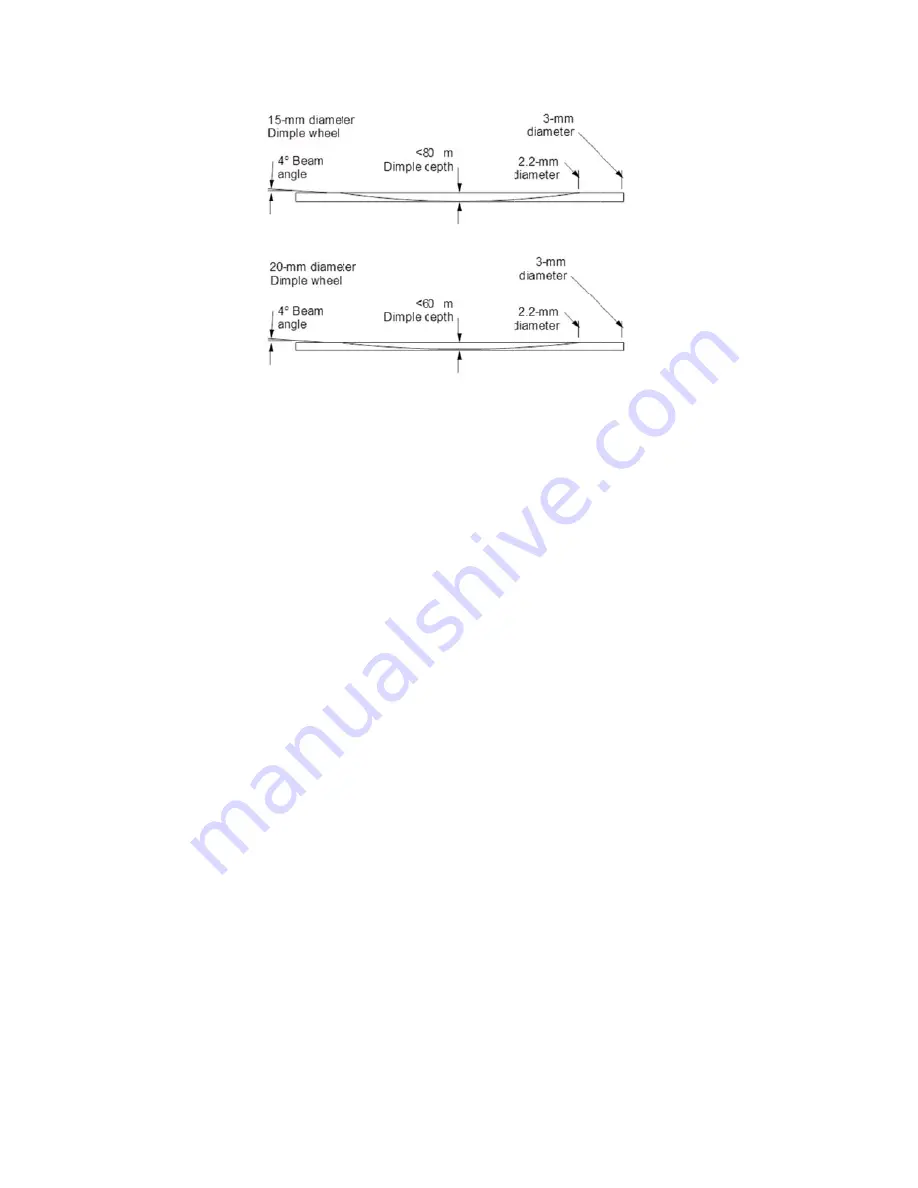

gure 4-7 Spe

he PIPS II do

ariety of sp

ounted direc

n polishing.

o obtain best

Refer to the

perating instr

After disc

he 15 mm p

m diamond

Dimple po

0-25 g load

bout 10 µm

ertain cerami

Dimple po

µm) using 0

Dimple po

bout 5 µm)

medium spee

OTE:

Us

ontamination

lease note th

nd silicon-ba

ers Guide

ecimen disc g

oes not use a

pecimen sha

ctly on a mo

t results wit

Gatan Mod

ructions.)

c grinding t

hosphor br

paste, 15-20

olish with fe

and low to

when mea

ics and semi

olish with a

0-2 µm diam

olish with a

) using 0.05

d.

se different

n.

hat the loads

ased materia

geometry.

any specime

apes. Rectan

odified spec

h dimple gri

del 656 Dim

to 40-70 µm

ronze wheel

0 g load and

elt wheel for

medium sp

surable, and

conductors.)

new felt wh

mond paste,

a new felt w

5 µm Alum

felt wheels

s and speeds

als. For mat

en clamps an

ngular TEM

imen post a

inding, follo

mple Grinde

m, coarse dim

l to a thickn

d low to med

r 3-5 min us

peed.

(This i

d is possibl

)

heel for 5-6

20-25 gm lo

wheel for 8-1

mina suspen

for differen

s suggested

terials that a

nd hence it w

M tensile sp

and dimpled

ow the steps

er User's Gu

mple grind

ness of 20-2

dium speed

sing 2-4 µm

s equivalent

le with tran

min (or to

oad and me

10 min (or t

nsion, 20-3

nt abrasives

above work

are more bri

will accept a

pecimens ca

in place pri

described b

uide for det

the sample

25 µm using

d.

m diamond p

t to a thickne

nsmitted ligh

a thickness

edium speed

to a thickne

30 gm load

s to avoid c

k best for si

ittle, lower

84

large

an be

ior to

below

tailed

with

g 2-4

paste,

ess of

ht for

of 6-

d.

ess of

d and

cross-

ilicon

loads