16

CALIBRATION

GC16XD MINI CRIMPER & PUMP SAFETY & OPERATION MANUAL

Press and hold the pump power switch. The crimper will close down to the

position set while the center stem will rise on the dial vernier. Release the

switch once the stem becomes flush with the front face of the dial vernier.

Stopping the pump will allow the oil to return back to the tank and the head

will open.

Remove the assembly from the machine and measure across the flats of

the crimped area. This should read 1.000”. If the measurement does not

read 1.000” (+/- .003) then the micro adjuster needs to move until the

COD is correct.

Micro Adjustment

Loosen lock nut on back of micro adjuster using 8mm wrench. (It does not

need to be removed) Do this while holding a 2.5mm Allen key in micro adjuster

to ensure it does not rotate.

Use a 2.5 mm allen key to rotate micro adjuster following instructions on last

page to reach desired adjustment. When adjustment made tighten up lock nut

with Allen key still in micro adjuster ensuring it does not rotate.

Crimp the same hose again to check calibration. If crimper still not accurate

rotate micro adjuster as per chart until final diameter achieved.

Summary of Contents for GC16XD

Page 1: ...GC16XD MINI CRIMPER PUMP SAFETY AND OPERATING MANUAL Product Number 7480 7006...

Page 9: ...7 GC16XD MINI CRIMPER PUMP SAFETY OPERATION MANUAL THIS PAGE IS INTENTIONALLY BLANK...

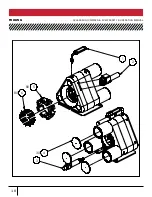

Page 11: ...9 CRIMPER GC16XD MINI CRIMPER PUMP SAFETY OPERATION MANUAL...

Page 22: ...20 NOTES GC16XD MINI CRIMPER PUMP SAFETY OPERATION MANUAL...

Page 24: ...22 7480 7006 70115 GC16XD Auto 428 3509 Ind 34008 M GATES COM Printed in the USA 09 2020...