Instructions for DKC500ACL/DKC800ACL

www.gatexpertstore.com

10

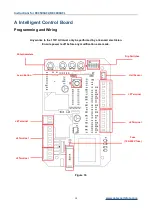

Figure 12

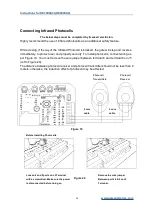

Step 6 - Sprocket and Chain & Motor Alignment

·

Ensure output sprocket and chain are correctly aligned. Under no circumstances should the

gate opener output sprocket carry any weight of the gate. It is the task of the gate castors or

wheels to carry the weight of the gate.

·

If the gate doesn’t slide freely by hand, adjust the height of the chain accordingly until the full

length of gate slides freely by hand.

·

Ensure the chain is in proper tightness after installation. (refer to Figure 14)

Figure 13