Instructions for PY300DCL

www.gatexpertstore.com

12

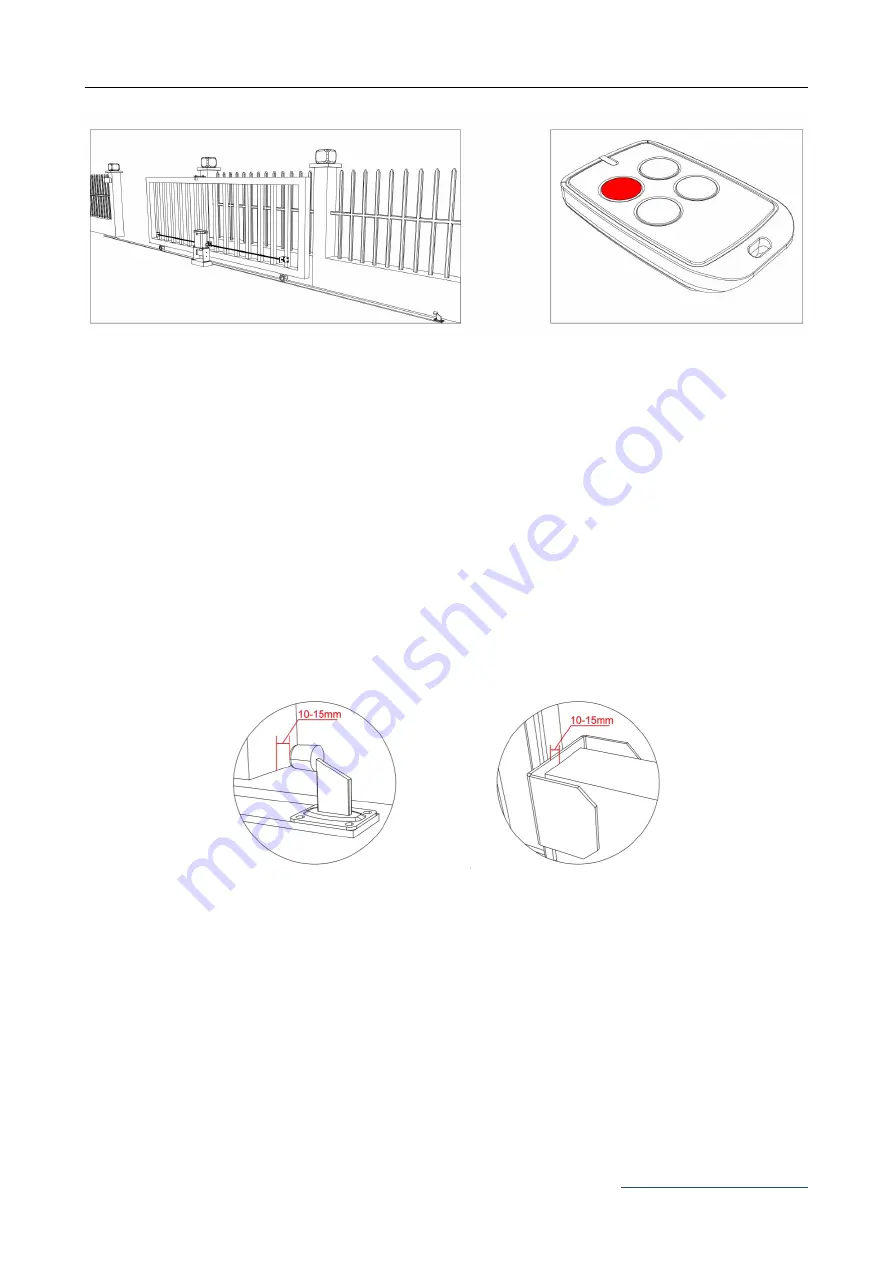

Figure 15

Step 8 - Testing Travel and Limit Stops

·

Ensure gate opener is installed as per step 5, 6 and the sliding gate is in the middle position.

·

Please refer to control board setting(page 15) to set the open limit stop position and closed limit

stop position. The ideal closed final position for the gate frame is 10-15mm from closed gate

end catch.

·

After setting up the limit stop positions, the sliding gate will automatically run to open limit stop

positon and then to the closed limit stop postion, do not cut off the power supply or stop the

gate during it’s Auto-running.

·

Press remote (remotes included in kit are factory paired to the motor) or exteral push button,the

sliding gate will begin to move. When it arriaves at the limit stop position the sliding gate will

stop.

Now the basic open and closed positions are set, for further setting functions and adjusting

parameters, please refer to pages 13-21 in this manual.

Open Limit Stop Position

Closed Limit Stop Position