TIRE CHANGER FOR TRUCK TWC-1600

7

using the machine.

11 CORRECT OPERATION CHECKS

Before using the tire changer, a number of checks should be made to ensure it

works correctly.

CAUTION! The operations described here should be done with the tool carrier

arm in its non-working position.

First use lever (15, Fig. d) to tip the arm to this position.

1) Move the joystick (8, Fig. c) up (a): the spindle carrier arm (2, Fig. a) should

lift; move the joystick down (b): the arm should lower. Move the joystick

towards the left (C): the tool carriage and the mobile platform (13, Fig. D)

Should move towards the spindle (3, Fig. A);move the joystick towards the

right (d) the carriage and platform should move away from the spindle.

2) Tum switch lever (9, Fig. C) towards the top: the spindle arm should

open; move the lever down and the spindle arms should close.

3) Depress the right pedal (10, 568 Fig. C): the spindle (2, Fig. A) should turn

clockwise; depress the left pedal: the spindle should turn anticlockwise.

4) Check to be certain the hydraulic circuit is working correctly:

-move switch lever (9, Fig .c) towards the top until the spindle arms are fully

extended.

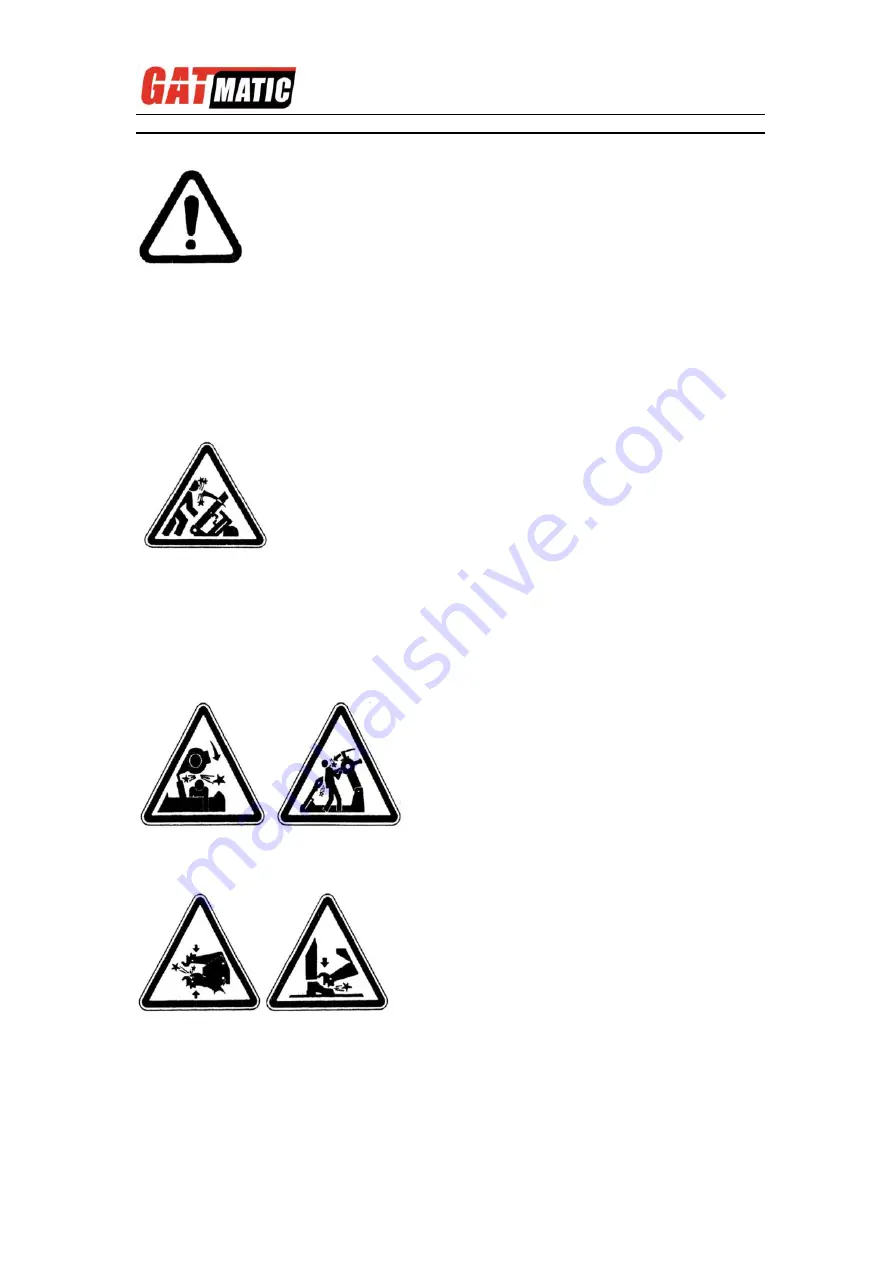

CAUTION!

Do not move your face close to the tool carrier arm when you

release it to tip it as needed.

DANGER!

When the spindle carrier arm is lowered. There is

always a potential for crushing anything in its

movement range. Always work from the position given

in the instructions keep well out of the working range

of the various moving arms.

(2, Fig. A)

DANGER!

When the spindle arms open or closed, there is always a

potential for crushing anything in their movement

range.

Always work form the position given in the instructions

keep well out of the spindle’s working range.

Lifting arm lift or lower and hydraulic chuck open or close, there is

always a potential for crushing anything in its movement range.

Always work form the position given in the instructions keep well

out of the working range