P.3

每一個插圖中的代號(#A,#B,#C…1,2,3…)僅代表該插圖中的某一零件,

同一插圖中若有相同尺寸之零件,會以相同代號代表,插圖代號僅供組裝參考用。

以上圖示,於組裝時請確實注意,避免組裝後試飛造成失控零件鬆脫等情況發生。

#A #B #C #D #E

#F

#G #H

#I #J

螺絲止鬆劑

螺絲止鬆劑-使用螺絲止鬆劑(適量使用)

Thread Lock

Thread Lock – Use the thread-lock

adhesive (right amount use)

組裝維修時請注意以下 警示圖案 。

Please note the following caution symbols during assembly

Code Letter/Number (#A,#B,#C…,1,2,3…) used in each figure indicates the

specific part in that figure only, please refer to the parts list for the

actual item numbers. Code Letter/Number is only for the reference in assembly.

Make sure to assemble the parts as shown in figure above, incomplete/

incorrect assembly may cause the control failure during flight.

螺絲止鬆劑上膠位置約為螺紋前端

1mm寬度。

IMPORTANT

Use the thread-lock adhesive if the

screws are tightened to the metal parts.

請注意

組裝時如遇螺絲鎖於金屬件,請適量

使用 螺絲止鬆劑 以確保飛行安全!

Use the thread-lock adhesive on the

tip of screw for 1mm width.

組裝代號說明

瞬間 膠

CA-以瞬間膠固定(適量使用)

CA- use CA adhesive

(right amount use)

CA

CA

B-Bearing

B-軸承

Ø

-Tap Screw

Ø

-粗牙螺絲

M-Machine Screw

M-公制螺絲

P-tube

P-柱狀體

Pillar

P-柱狀體

N-Nut

N-螺母

W-Washer

W-華司

B(Dia.in)x(Dia.out)x(Thickness)

B(內徑)X(外徑)X(厚度)

Ø

(Dia.out)x(Length)

Ø

(外徑)X(長度)

M(Dia.out)x(Length)

M(外徑)X(長度)

P(Dia.in)x(Dia.out)x(Length)

P(內徑)X(外徑)X(長度)

P(Dia.out)x(Length)

P(外徑)X(長度)X(實心柱)

N(Dia.in)x(Width) L-Lock nut

N(外徑)X(總高)

W(Dia.in)xDia.out)x(Thickness)

W(內徑)X(外徑)X(厚度)

Figures instruction

Mark 類別

indication 標示 (mm)

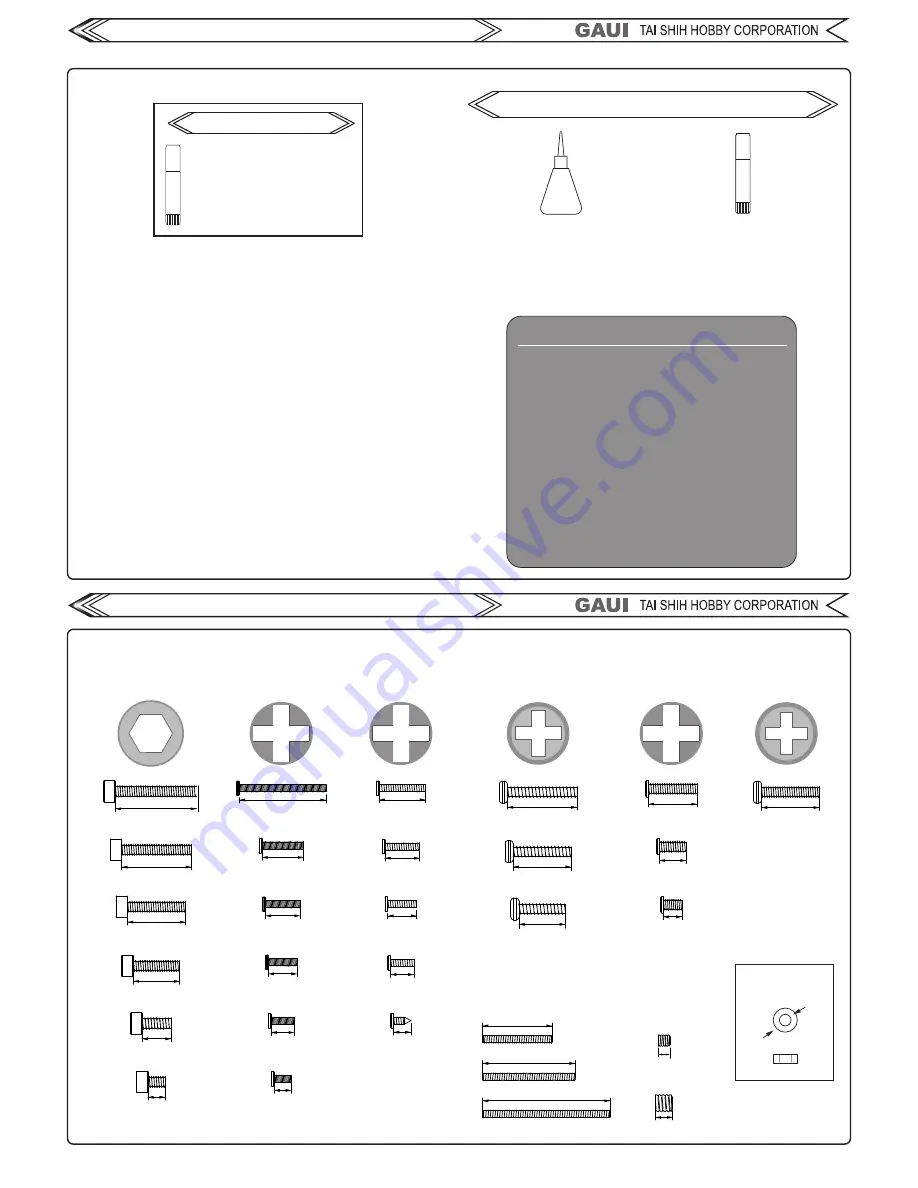

Specification of Screws ( 1 : 1 )

螺絲規格對照圖(1:1)

Ø2.0

Self taping screws

M2.0

Tiny head machine

screws

M2.0

Machine screw

M2.0

Socket head machine

screws

M2.0

Socket set screws

Linkage rods

M2螺絲

M2小頭螺絲

M2六角螺絲

止付螺絲

Washer華司

內徑

外徑

厚度

拉桿

Ø

2螺絲

M1.4

Machine screws

Ø

1.4

Self taping screws

M1.4螺絲

Ø

1.4螺絲

8.0

3.0

4.0

5.0

6.0

12.0

8.0

10.0

10.0

8.0

12.0

3.0

5.0

10.0

14.0

3.2

8.4

4.6

15.0

3.0

4.0

5.0

6.0

7.0

M

3

3.0

M

2

2.0

16.0

12.0

22.0

① ② ③ ④ ⑤

⑥ ⑦ ⑧ ⑨ ⑩

Dia.in

Dia.out

Thickness

Summary of Contents for Hurricane 255

Page 28: ......