4

3.

Technical data

Article code

: 67032

DVGW approval

: -

Pressure class

: PN16

Nominal width

: DN10

Connection

: G¼

Service temperature : -20 / 70°C

Service life

:

> 10.000x

connecting and

disconnecting

operations

Materials

:

AiMgSi1

Stainless steel

POM

NBR Rubber

EPDM

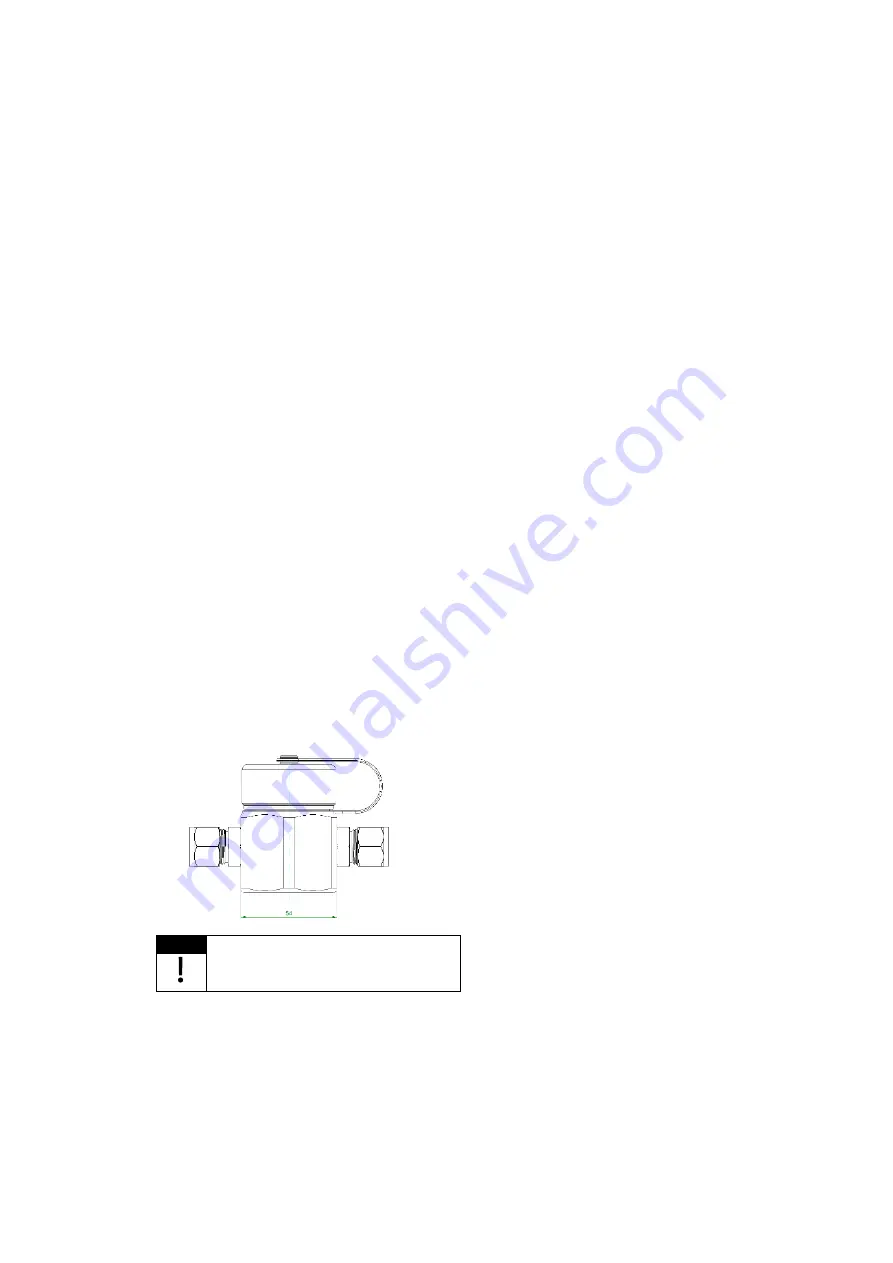

4.

Mounting

Before mounting the gDC-100 please

make sure the flow direction of the gas

station and the arrow of the coupling

(see bottom of the coupling) points in

the same direction. The PLEXOR

®

*

inspection system will not function

correctly if the gDC-100 is installed

wrongly. The gDC-100 can best be

mounted horizontally in the forward

position, to reduce the

risk of internal and external

contamination. Please make sure that

there is enough space for easy

connection with the PLEXOR

®

*

hose

connector.

5.

Use

5.1 Connecting the gDC-100 to the

PLEXOR

®

*

inspection system:

•

Unscrew the protective cap from

the gDC-100.

•

Connect the hose connector to the

test device. For this, refer to the

PLEXOR

®

*

test device manual.

•

Screw the hose connector on the

gDC-100 until it is hand tight. For

this, refer to the PLEXOR

®

*

test

device manual.

The PLEXOR

®

*

inspection system is

now safely connected to the gDC-100.

5.2 Disconnecting the gDC-100 from

the PLEXOR

®

* inspection system.

•

Loosen the hose connector from

the gDC-100.

•

De-aerate the PLEXOR

®

*

test

device. For this, refer to

PLEXOR

®

* test device’s manual.

•

Completely loosen and remove the

hose connector from the gDC-100.

•

Screw the gDC-100’s protective

cap back on.

6.

General maintenance

Maintenance of the gDC-100 is

restricted to replacing the O-rings. The

expected service life of these O-rings

is at least 20 years.

Note

If the gDC-100 is to be installed in a new

duct, it is recommended, to bend and install

the duct without the gDC-100 first and then

place the gDC-100 as shown in figure above