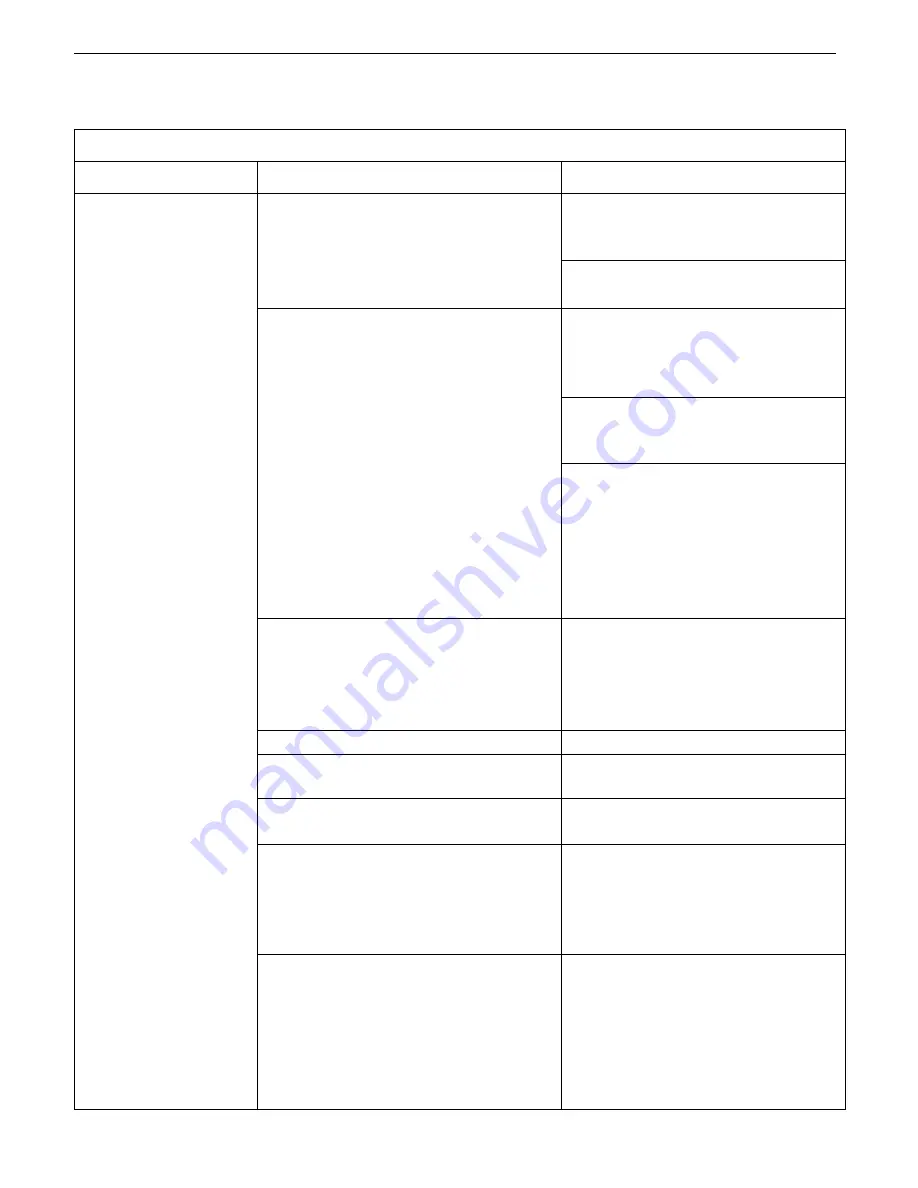

______________________________________________________Chapter 5 - Troubleshooting, Page 5-5

Wash System

Symptom

Probable Cause

Corrective Action

1

The Wash Cycle is

not adequately

cleaning the

Extraction

Chamber, the

Particulate

Separators the UV

Lamps or the ESP

Cells

A. The water supply is turned off or

partially off.

1 Check the hand valves inside the

Wash Control Cabinet. Refer to

Figure 2-11-2.

2 Check any valves upstream of

the Wash Control Cabinet.

B. Low Water Pressure - Check the

water pressure gauge inside the

Command Center cabinet.

Pressure should be 60 psi min.

while the Ventilators are washing.

1 Check the hand valves inside the

Wash Control Cabinet to make

sure they are fully opened.

Refer to Figure 2-11-2.

2 Check any valves upstream of

the Wash Control Cabinet to

make sure they are fully opened.

3 The Line Strainer inside the

Wash Control Cabinet may be

clogged. Refer to the Technical

Manual for the Gaylord

Command Center and Wash

Control Cabinet for instructions

on cleaning the Line Strainer.

C. Low Water Temperature - Check

the temperature gauge inside the

Wash Control Cabinet. The

temperature should be between

140 degrees F. to 180 degrees F.

1 If below temperature it must be

increased at the hot water

source.

D. Inadequate length of Wash Cycle. 1 Refer to Page 3-9

for guidance.

F. Detergent tank empty.

1 Check and fill the detergent tank

at least weekly.

G. Improper detergent.

1 Refer to Page 3-10 for

recommended detergent.

H. Detergent pump has lost its prime

or is malfunctioning.

1 Refer to the Technical Manual

for the Gaylord Command

Center and Wash Control

Cabinet, the Troubleshooting

section.

I. Clogged Spray Nozzle(s).

1 While the Wash Cycle is on,

open the Extractor Inspection

Door slightly and visually inspect

the spray of the nozzles. If

clogged, remove and clean by

running a small wire through the

orifice.

Table T-5-5-1