4-1

Chapter 4 - Troubleshooting

Troubleshooting

Using the Troubleshooting Charts

The following Troubleshooting Charts are designed to easily find common problems, the probable cause and

guidance on corrective action. In some cases the Corrective Action column will reference the Testing and

Repair section of this manual for additional guidance and actions.

1

1 Check exhaust fan for broken or slipping belts. Adjust

or replace belts as required.

2 Confirm proper rotation of fan wheel.

3 Check for proper size of exhaust fan. Fan must deliver

Ventilator Nameplate rating.

4 Check and adjust Gaylord Balancing Damper as

described pages 2-19

of this manual.

5 Check for open access panel in duct system and close or

re-install if open.

B. Exhaust volume is low due to a heavy

grease accumulation on the Extractors.

1 Remove the Extractors and inspect for grease

accumulation. If the extractors are not being washed

effectively refer to the Troubleshooting section on

WASH CYCLE.

C. The Ventilator must have its own exhaust

system and no other exhaust, such as

dishwasher hoods should be tied into it.

1 Inspect the duct system and verify that there are no

other non Type I Ventilator systems tied in. If so they

must be removed.

D. Improperly placed make-up air diffusers.

1 Make-up air directed at the Ventilator will likely create

cross drafts disrupting the air flow into the Ventilator.

Adjust the louvers to direct the make-up air away from

the Ventilator. Refer to page 5-5

for guidance.

2 Make-up air should be delivered through registers at

ceiling height, and distributed throughout the kitchen

area. Refer to page 5-5 for guidance.

3 Make-up air registers located near the Ventilator, the

louvers should be adjusted to direct the air away from

the Ventilator. Directing or forcing the make-up air at

the Ventilator typically creates cross drafts resulting in

smoke loss. Refer to page 5-5 for guidance.

E. Inadequate make-up air

1 Make-up air must be supplied for replacement of air

exhausted through all kitchen exhaust systems. Refer

to page 5-5 for guidance.

2 A general "rule of thumb" is that 60% of the

replacement air should be fresh, conditioned, (heated

or cooled) air brought into the kitchen area, with the

remaining 40% allowed to flow into the kitchen from

adjacent areas. Refer to page 5-11 for guidance.

F. Exhaust fan discharge

1 There should be no screen over the discharge. If one is

found, it should be removed.

2 The direction of discharge should not be into the

prevailing winds nor downward onto the roof. A

vertical discharge is highly recommended.

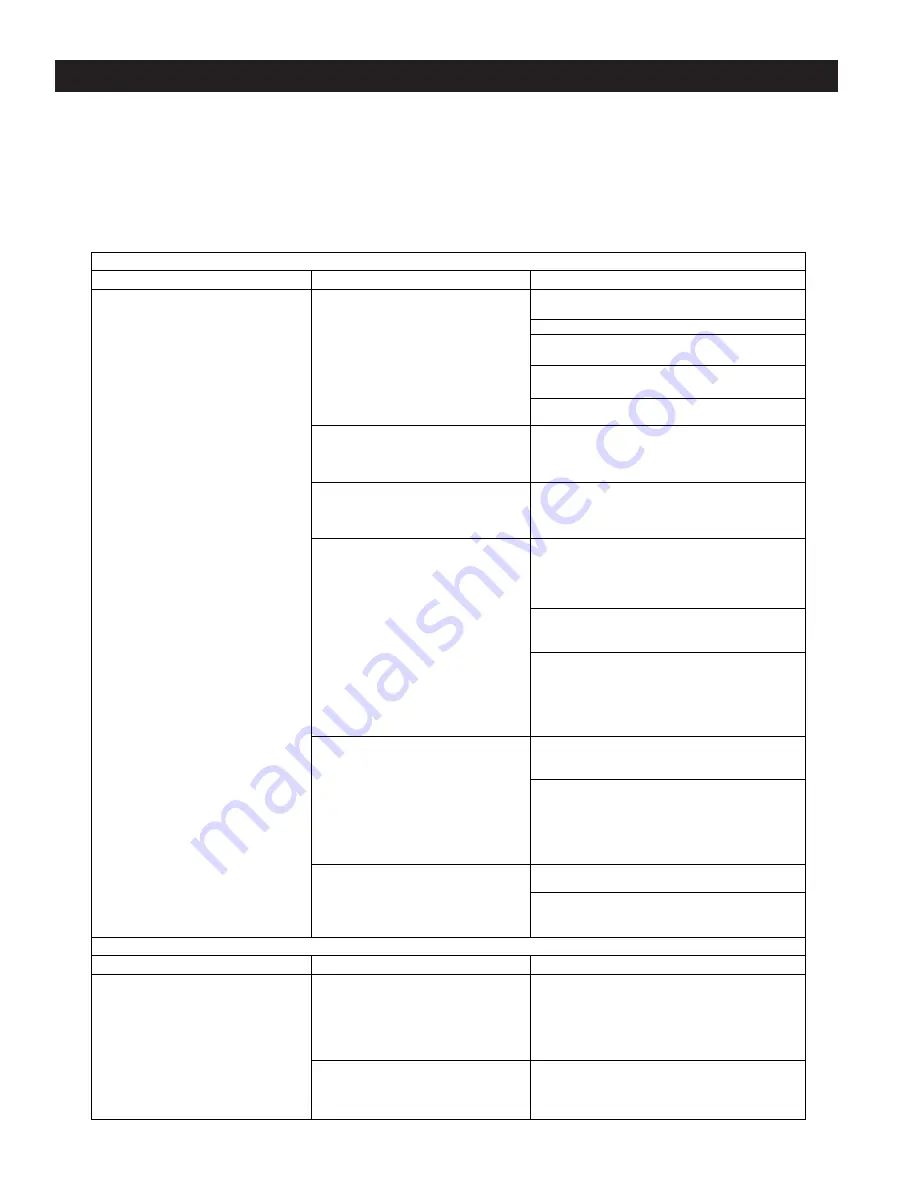

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

1 Poor grease extraction.

A. Ventilators exhausting too much air can

cause an excessive amount of noise and

allow grease to be pulled through the

Extractors. Ventilators exhausting below

design will also allow grease to be pulled

through the Extractors.

1 Check for proper exhaust volume by following the

instructions beginning on page 5-1.

B. Sticky grease may have accumulated within

the Extractors, creating a higher velocity

within the Extractors allowing grease to be

pulled through.

1 Remove the Extractors and inspect for grease

accumulation. If the extractors are not being washed

effectively refer to the Troubleshooting section on

WASH SYSTEM.

Chapter 4, Page 4-1

PROBABLE CAUSE

SYMPTOM

GREASE EXTRACTION

Exhaust volume is low due to fan

performance issues or a Gaylord Balancing

Damper, is not adjusted properly. Measure

the exhaust volume as described on page 5-

1 through 5-4.

A.

CORRECTIVE ACTION

The Ventilator is not exhausting all the

smoke, heat and grease properly.

SMOKE LOSS

Troubleshooting

Summary of Contents for ELXC Series

Page 40: ...4 6 INTENTIONALLY LEFT BLANK ...

Page 74: ...7 1 Chapter 7 Wiring Diagrams ELXC GBD with AUTOSTART ...

Page 75: ...7 2 Chapter 7 Wiring Diagrams ELXC GFBD with AUTOSTART ...

Page 76: ...7 3 Chapter 7 Wiring Diagrams ELXC GBD UVi with AUTOSTART ...

Page 77: ...7 4 Chapter 7 Wiring Diagrams ELXC GFBD UVi with AUTOSTART ...

Page 83: ...A 6 INTENTIONALLY LEFT BLANK ...