5-23

Chapter 5 - Testing and Repair

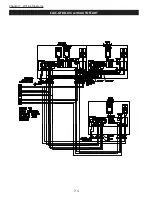

Ventilator Water Solenoid Valves

Overview

There are two water Solenoid Valves located on the top of each Ventilator section. One is for Plenum Wash

and one for the Extractor Wash (Refer to Figure A-5-1). The Solenoid Valves are controlled by the Gaylord

Command Center.

Sticking Solenoid Valve

If water is running when the Command Center is not in a Wash Cycle it indicates that the Water Solenoid

Valve is stuck in the open position. If this is the case, perform the following: (Refer to Figure 5-24-1)

1. Gently tap the valve housing with a hammer. This should release foreign material trapped in the valve

and the water should stop.

2. If tapping does not release the foreign material the valve must be disassembled and checked. To disas

-

semble the valve proceed as follows:

Danger

: Always shut off electrical power when repairing electrical controls. Contact with unsecured

power will result in immediate injury or death to personnel.

a) Shut off electric power to the Wash Control Cabinet.

b) Pry up the Red Cap on the top of the Solenoid and slide the Solenoid Coil off the coil stem.

c) Remove the four bolts to separate the valve casing.

d) Remove the valve diaphragm, inspect and clean. Clean both half’s of the valve casing.

e) Reassemble in reverse order.

f) If the diaphragm looks worn or defective it should be replace with a Solenoid Valve Repair Kit (Refer

Chapter 6, Ventilator Parts).

If solenoid valve sticking is a recurring problem, it indicates that foreign material in the water supply line

is escaping through the line strainer located in the Wash Control Cabinet. The screen in the line strainer

should be removed, checked for holes, and cleaned. For instruction, refer to the Operation, Installation &

Maintenance Manual for the Command Center / Wash Control Cabinet.

Solenoid Valve Not Opening

If a Solenoid Valve does not open when the system is placed into a Wash Cycle perform the following:

1. Check to see if there is electrical power at the solenoid coil. If there is no power refer to the Operation,

Installation & Maintenance Manual for the Command Center / Wash Control Cabinet, the Troubleshooting

Section.

2. If there is power it indicates that the Solenoid is burned out. To replace the Solenoid proceed as follows:

Danger

: Always shut off electrical power when repairing electrical controls. Contact with unsecured

power will result in immediate injury or death to personnel.

a) Shut off electric power to the Wash Control Cabinet.

b) Open the junction box next to the Solenoid Valve and disconnect the valve wires.

c) Lift up the tab on the Solenoid Retainer and slide the retainer off.

d) Slide the Solenoid Coil off the coil stem.

e) Pull the wires out of the conduit going to the junction box.

Summary of Contents for ELXC Series

Page 40: ...4 6 INTENTIONALLY LEFT BLANK ...

Page 74: ...7 1 Chapter 7 Wiring Diagrams ELXC GBD with AUTOSTART ...

Page 75: ...7 2 Chapter 7 Wiring Diagrams ELXC GFBD with AUTOSTART ...

Page 76: ...7 3 Chapter 7 Wiring Diagrams ELXC GBD UVi with AUTOSTART ...

Page 77: ...7 4 Chapter 7 Wiring Diagrams ELXC GFBD UVi with AUTOSTART ...

Page 83: ...A 6 INTENTIONALLY LEFT BLANK ...