13

MEASURING INLET SLOT VELOCITY

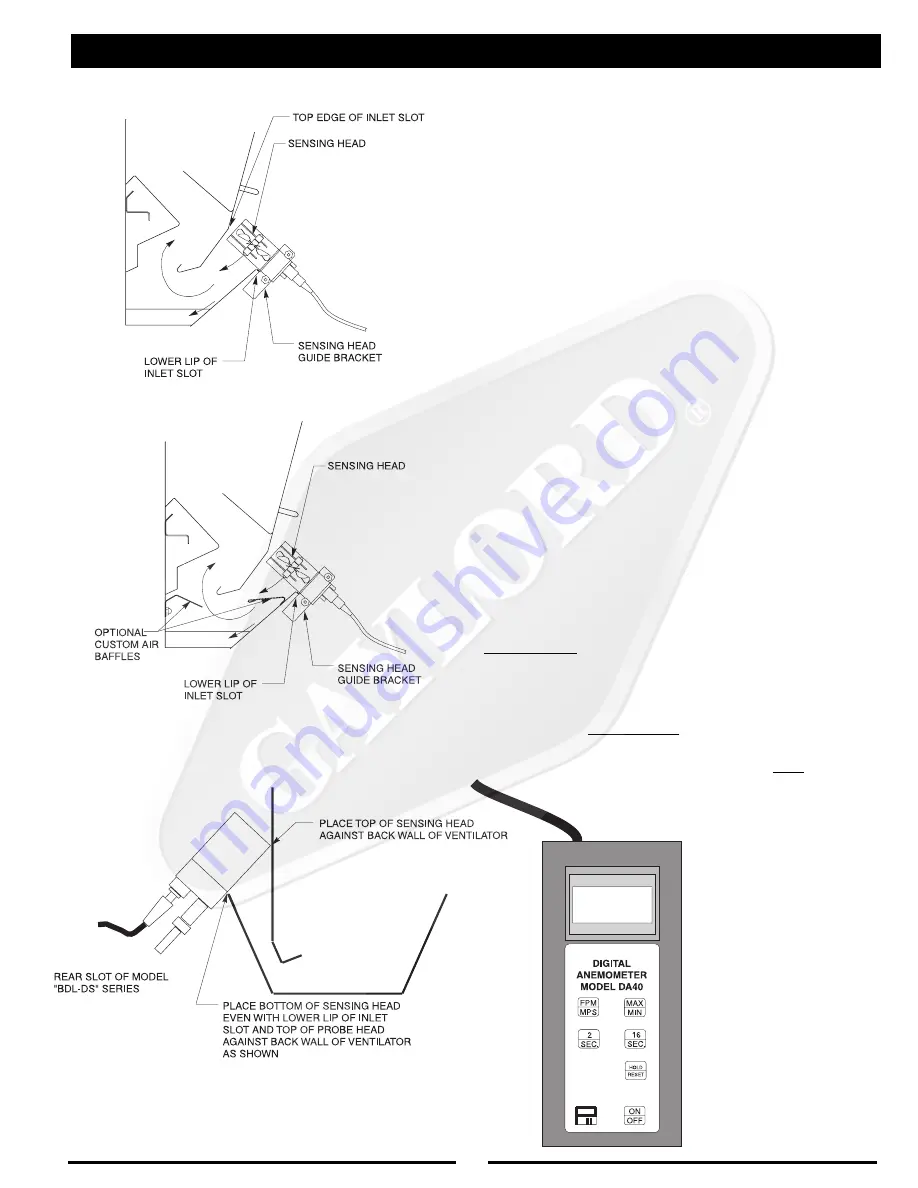

FIG. 5A

FIG. 5B

FIG. 5C

CROSS SECTION OF TYPICAL

VENTILATOR INLET SLOTS

The standard instrument used for measuring the inlet velocities on a Gaylord

Ventilator is a Pacer, Model DA40 or DA4000 Digital Anemometer. This

instrument is the easiest, most accurate and the best suited for measuring

ventilator inlet slot velocities. To take accurate air velocity readings, follow

the instructions below.

Instructions

1. It is first necessary to determine if the ventilator includes Custom Air baffles

as shown in Fig. 5B. If shop drawings are available, and if equipped, the

custom baffles and their location will be noted on the front elevation. If not

available, to determine if Custom Air baffles are provided run your hand along

the bottom inlet slot and feel for the Custom Air baffle as illustrated in Fig. 5B.

2. If the ventilator includes Custom Air baffles, it will be necessary to take two

sets of readings - one for the section of ventilator that includes Custom Air baffles

and one where it does not.

3. Attached the sensing head guide bracket, Gaylord Part Number 18408, to

the sensing head.

4. Attach the cable from the sensing head to the meter and the handle

sections to the sensing head.

5. Place the sensing head guide bracket against the lower lip of the inlet slot

as illustrated.

6. Using the 16 second averaging feature on the meter, slide the sensing head along

the slot, back and forth, for a 3'-0" to 4'-0" distance, and record the velocity at the end

of the 16 second mark. Continue this process for the full length of the ventilator.

Important Note: If the ventilator includes custom air baffles as illustrated in Fig.

5B, always take separate readings on the section of the ventilator that includes

custom air from the section that does not have the baffles. Non custom air and

custom air readings must be recorded separately. Do not average them together.

Important Note: On the rear slot of a Model BDL-DS Series, do not use the

guide bracket. Refer to Figure 5C.

7. Record the velocity (fpm) on the start up inspection report form. A sample

report form, which can be photocopied, is provided on page 16.

8. The designed, or optimum velocity, is noted on the shop drawings and

the Air Velocity Chart on page 12. Two velocities will be noted if the ventilator

includes custom air baffles.

9. Compare the recorded air velocity to the designed air velocity shown on the

shop drawings or the Air Velocity Chart on page 12. The recorded velocity may

be slightly lower or higher providing that it is within the minimum and maximum

range as shown on the Air Velocity Chart .

If the air velocity is outside the minimum/maximum range, the performance of

the ventilator will be affected and therefore the exhaust fan must be adjusted.