14

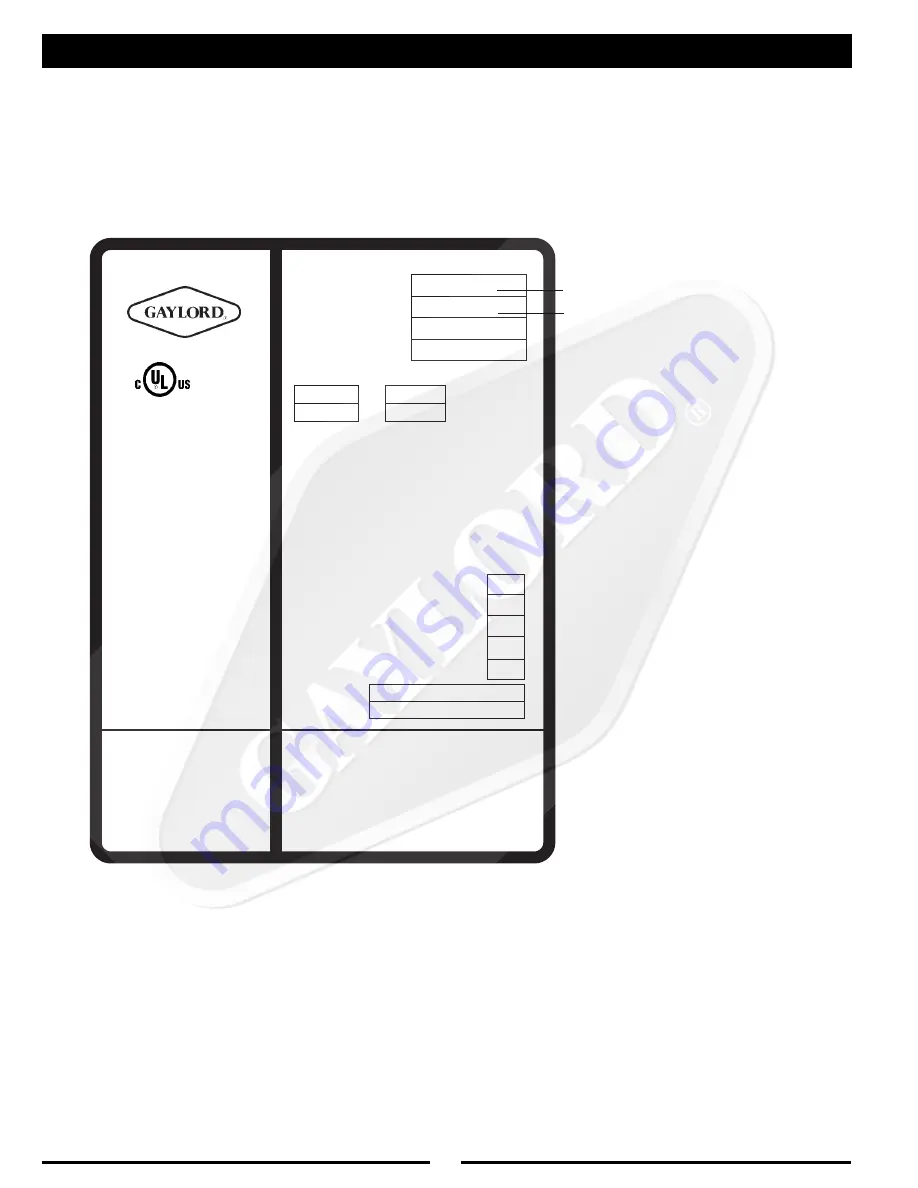

1. MINIMUM TOTAL EXHAUST

VOLUME FOR THIS HOOD SECTION

2. MAXIMUM TOTAL SUPPLY

VOLUME FOR THIS HOOD SECTION

3. EXHAUST STATIC PRESSURE AT

DUCT COLLAR

4. SUPPLY STATIC PRESSURE AT

DUCT COLLAR

5. THIS HOOD SECTION SUITABLE FOR APPLIANCES WITH MAXIMUM COOKING

SURFACE TEMPERATURE OF:

˚F FOR

LINEAL FT. OF HOOD

˚F FOR

LINEAL FT. OF HOOD

6. REFER TO GAYLORD VENTILATOR TECHNICAL MANUAL FOR INLET

VELOCITY REQUIREMENTS AND METHOD OF CHECKING VELOCITY

7. ELECTRICAL RATING OF LIGHT FIXTURES: 120 VOLT, 60 HZ. OR 220 VOLT,

50 HZ. OVERALL RATING - 12 AMPS OR LESS

8. ON "GX2" and "PG" SERIES VENTILATORS EQUIPPED WITH FUSE LINK

OPERATED EXHAUST FIRE DAMPER USE ONLY 280˚ F , RATED 30 LBS. MIN. UL

LISTED FUSIBLE LINK FOR REPLACEMENT

9. IF HOOD IS EQUIPPED WITH INTEGRAL MAKE-UP AIR WITH FUSE LINK OPER-

ATED FIRE DAMPER USE ONLY 165˚ F, RATED 30 LBS. MIN. UL LISTED FUSIBLE

LINKS FOR REPLACEMENT

10.DUCTWORK AND EXHAUST FAN

A. STATIC PRESSURE OF DUCT SYSTEM MUST BE ADDED TO VENTILATOR

STATIC FOR TOTAL SYSTEM STATIC

B. ALL DUCTWORK MUST BE WELDED LIQUIDTIGHT

HOOD MOUNTING REQUIREMENTS

MINIMUM DISTANCE FROM COOKING SURFACE TO FRONT

LOWER EDGE OF HOOD

MAXIMUM DISTANCE FROM COOKING SURFACE TO FRONT

LOWER EDGE OF HOOD

MINIMUM OVERHANG FROM FRONT OF HOOD CAVITY TO

FRONT OF COOKING SURFACE

MAXIMUM SETBACK FROM FRONT OF HOOD CAVITY TO

FRONT OF COOKING SURFACE

MINIMUM OVERHANG FROM SIDE OF HOOD TO EDGE OF

COOKING SURFACE

SERIAL NO:

MODEL NO:

W.G.

W.G.

ENGINEERING DATA

THIS EXHAUST HOOD HAS BEEN TESTED

TO STANDARD UL 710 "EXHAUST HOODS

FOR COMMERCIAL COOKING

EQUIPMENT"

THIS EXHAUST HOOD IS LISTED UNDER UL

FILE NUMBER 11403

THIS EXHAUST HOOD MEETS ALL REQUIRE-

MENTS OF THE LATEST EDITION OF NFPA-

96 AND THE IMC (INTERNATIONAL MECHANI-

CAL CODE)

o

SUPPLIED WITH FACTORY INSTALLED UL LISTED

GRINNELL CORP. EA-1, 1/4" ORIFICE, 65 DEGREE

DEFLECTOR SPRINKLER(S) FOR THE PROTEC-

TION OF UNLIMITED LENGTH OF GREASE DUCT

HAVING A MAXIMUM DUCT PERIMETER OF 50

INCHES PER SPRINKLER. CONNECT TO NFPA 13

SPRINKLER SYSTEM WATER SUPPLY ONLY.

PATENT PENDING

EXHAUST

HOOD WITH

EXHAUST DAMPER

UL-GX2/PG 1000

WORLD HEADQUARTERS

GAYLORD INDUSTRIES, INC.

10900 S.W. AVERY STREET

TUALATIN, OR 97062-8549 USA

PHONE: 1-503-691-2010

FAX: 1-503-692-6048

EMAIL: info@gaylordusa.com

LISTED

370Y

C.F.M.

C.F.M.

MAINTENANCE INSTRUCTIONS

1. REMOVE, INSPECT AND CLEAN FILTERS OR GAYLORD EXTRACTOR

CARTRIDGES AS REQUIRED

2. REMOVE AND EMPTY GREASE CUP AS REQUIRED

3. CAUTION - DO NOT OPERATE VENTILATOR WITHOUT FILTERS OR EXTRACTOR

CARTRIDGES IN PLACE

4. REPLACE FILTERS IN "PG" SERIES ONLY WITH UL CLASSIFIED GREASE FILTERS.

IN "PGX" AND "GX2" SERIES REPLACE WITH GAYLORD INDUSTRIES

EXTRACTOR CARTRIDGES.

5. IF THE VENTILATOR(S) HAS A FUSE LINK OPERATED EXHAUST OR SUPPLY

DUCT FIRE DAMPER THE NATIONAL FIRE PROTECTION ASSOCIATION'S

PAMPHLET NFPA-96 REQUIRES INSPECTION OF THE FUSE LINK EVERY 6

MONTHS AND REPLACED ANNUALLY. REFER TO THE GAYLORD VENTILATOR

TECHNICAL MANUAL FOR DETAILS.

The total required exhaust volume can be

found stamped on the UL nameplate located

on each hood section.

FIGURE 6

MEASURING INLET SLOT VELOCITY

TOTAL EXHAUST CFM HERE

TOTAL SUPPLY CFM HERE