5

The Gaylord “GX2-UV” Series Non Water-Wash Ventilator

offers simplicity, economy and performance that no other

ventilator can offer. The unique “extractor insert” gives a

grease extraction efficiency far superior to that of a typical

baffle filter. The Gaylord “GX2-UV” Series Ventilators are UL

Listed and meet all the requirements of NFPA #96 and the

International Mechanical Code.

EXHAUST FAN OPERATION

The exhaust fan is controlled by the Gaylord CUV-100 Control

Cabinet. The cabinet is usually located on a wall near the

ventilator. When the control is turned on, the exhaust fan and

UV Lamps will come on.

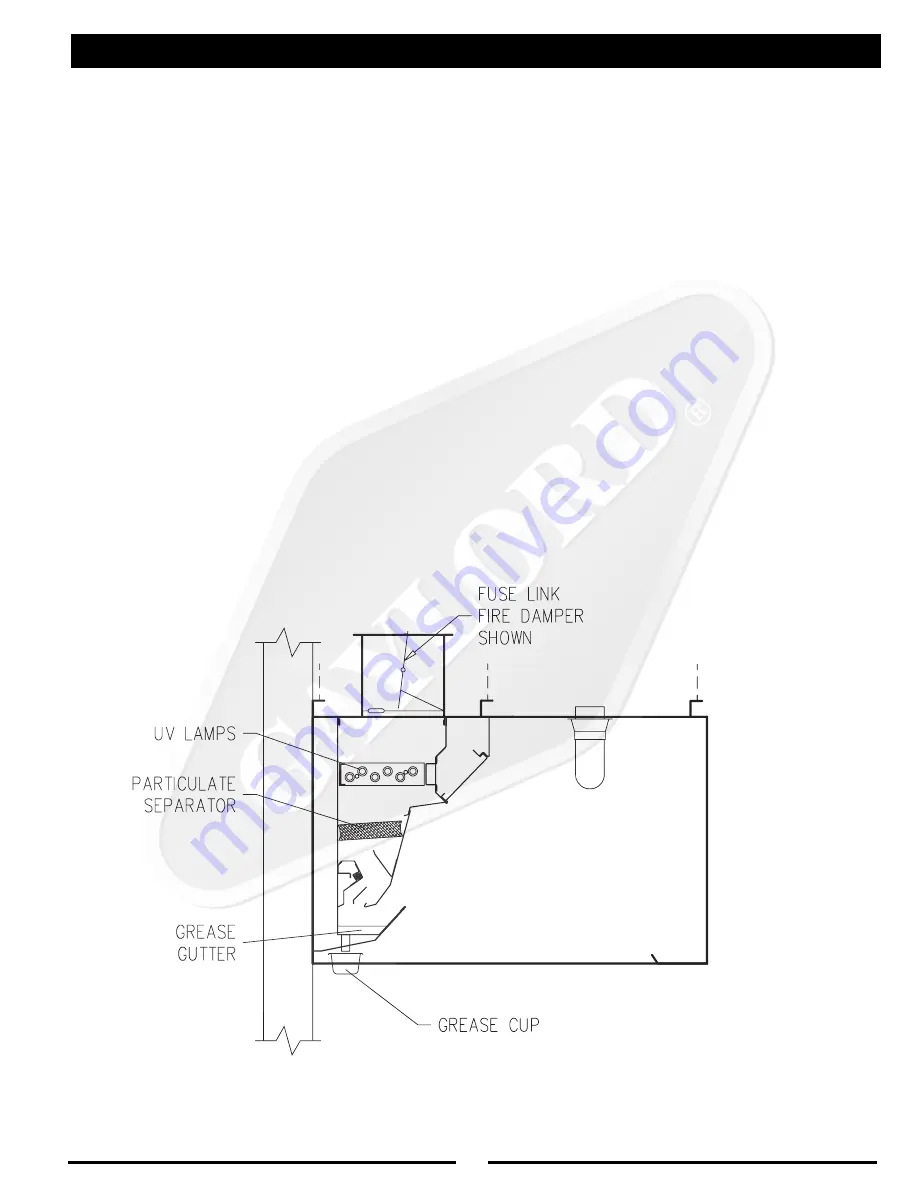

GREASE EXTRACTION

The Gaylord “GX2-UV” Series Ventilator extracts up to 99%

of the grease, dust, and lint particles from the airstream

passing through it. Grease extraction is accomplished by

unique, removable stainless steel “extractor inserts” which

incorporate a series of horizontal baffles. As the air moves

through the extractor at high speed, it is forced to make a

series of turns around these baffles, forcing the heavier-than-

air particles of grease, dust, and lint to be thrown out of the

airstream by centrifugal force. The sticky grease collects in

the extractor and the liquified grease drains down into the

main grease gutter which slopes to the grease cup. Note:

“GX2-UV” SERIES PRINCIPLE OF OPERATION

Some ventilators may be equipped with optional “Custom Air”

baffles (shown dotted) to reduce the exhaust volume over

specific light duty cooking appliances. The extractor inserts

come in two sizes15½" (5.6 lbs.) and 19½" (6.75 lbs.).

Particulate Separator

Once the largest particles of grease have been captured

through inertial impaction by the baffles. The smaller particles

of grease will be arrested in the particulate separator using the

principles of diffusion and inertial impaction.

UV Lamps

Once the baffles and particulate separators have collected the

grease particles larger than 1 micron. The UV lights will be

able to break down the remaining grease by direct exposure

to 254nm light and by the Ozone, Hydroxyl Radicals and

Anionic oxygen created by the 187nm UV light. This will carry

down the ductwork and continue to break down the grease,

particulate and odor molecules keeping the ductwork much

cleaner. The byproducts of this process are CO

2

, H

2

0 and the

base minerals from the grease and particulate matter coming

off of the cooking surface. There will be a light gray dust that

collects on the lamps, which will be need to wiped off. The

ductwork will need to be inspected per NFPA-96 schedules

but, will need much less frequent cleaning.

IMPORTANT NOTE: Never operate ventilator without extrac-

tor inserts in place.

GREASE EXTRACTION

FIG. 1