7

UV PREVENTATIVE MAINTENANCE CONTINUED

SAFETY CONCERNS WITH UVC

12. Check all wires for damage

• Replace any wires showing damage

13. Lubricate each of the new UV lamp(s) before installing with a

small amount of G-510 or similar detergent

14. Re-connect the lamp connectors on both ends of the UV lamps

• Each lamp connector should be labeled from 1 to 6 on

both ends

• Lamp #1 is at the Front of the ventilator when the UV

module is installed

• Lamp #6 is at the Back of the ventilator when the UV

module is installed

15. Re-install the UV module end caps and torque the bolts to

7-10 in-lbs.

16. Re-install the UV module in the ventilator

17. Tighten all nuts holding the UV module to the ventilator

18. Re-connect the UV module power cord

19. Check for proper operation of UV lamps & interlocks

Warning:

Do

NOT

defeat any interlocks during cleaning and maintenance!

CERTIFIED SERVICE AGENT MAINTENANCE WARNING!

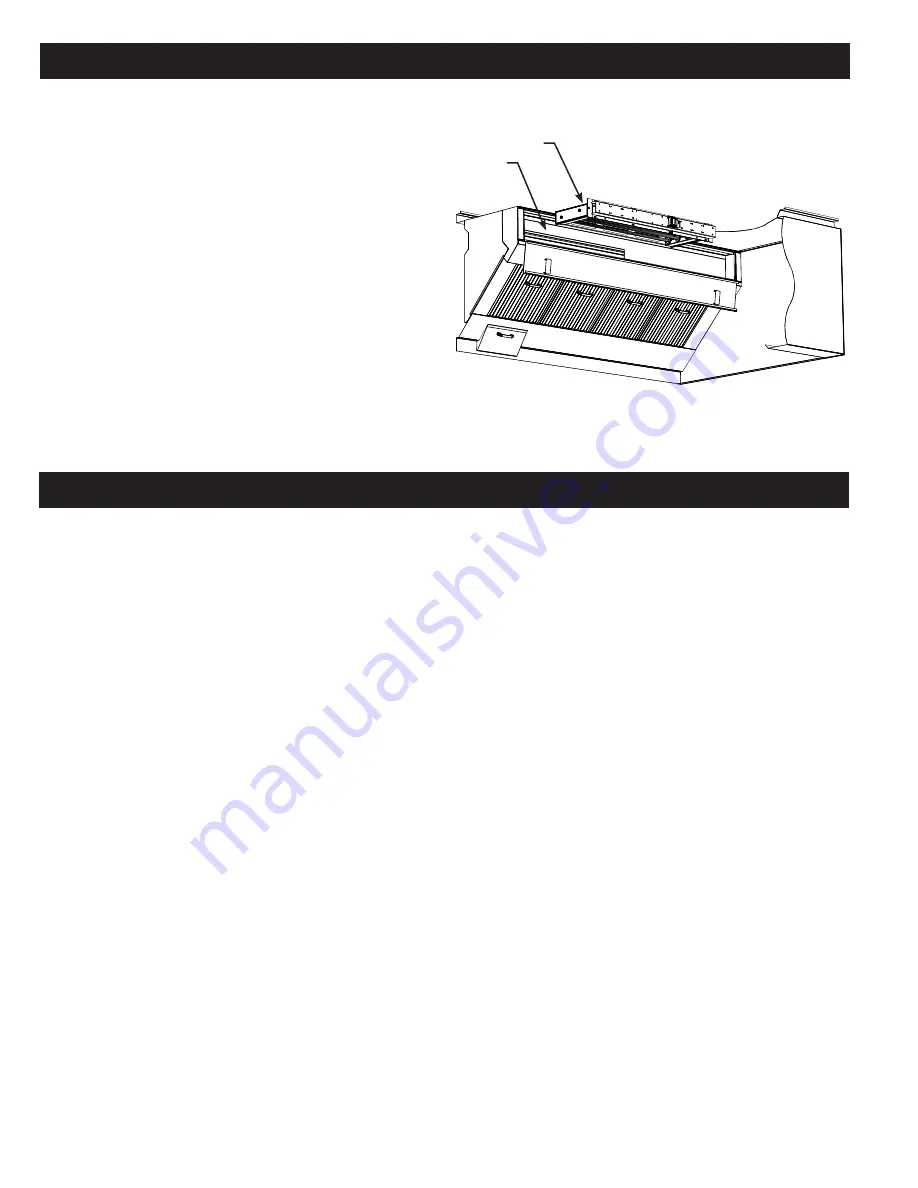

UV Chase

UV Module

FIGURE 12

As with many types of technology if it is not used properly and/or

proper precautions are not taken there is the potential for injury

or harm. This is especially true with UVC light due to the fact that

it does not physically hurt at the time of exposure. While UVC is

very effective at breaking down grease molecules, direct exposure

to large amounts is harmful to skin and eyes. The amount of UVC

generated in these hoods is greater than that what results from

direct exposure to the sun. Under no circumstances is it acceptable

to view the lighted lamps without proper eye protection or expose

bare skin directly to the light. All interlocks and safety precautions

called for in this manual must be followed to avoid the potential for

harm to service personnel and/or operators. In addition, only trained

and authorized personnel may perform some maintenance See

previous page for details.

Personal Protective Equipment

1.

Eye protection that prevents 100% of UVC being transmitted

through the lens must be worn at all times when performing

service work on any Ultima Vent that is energized and/or has

the potential to be energized and expose personnel to UVC

light.

2. Whenever service work is performed it is recommended that

long sleeve pants and shirts be worn to minimize the potential

for inadvertent exposure of the skin to UVC.

Safety Interlocks

This product comes equipped with the following sensors to verify that

all access doors are in place and that the exhaust fan is running:

1.

Mechanical door switch on the UV Access door to ensure that

the door is closed

2. XG Extractor magnetic switches to ensure each extractor is

installed.

3. Air Pressure switch to verify air flow and exhaust fan

operation

All of these devices must be working and/or adjusted properly in

order for the system to operate properly.

Summary of Contents for XG-BDL

Page 13: ...10 GFBD EXTERNAL WIRING MULTIPLE SECTION FIGURE 16B GFBD External Wiring Diagram ...

Page 29: ...26 UV HOOD WIRING BOARD SCHEMATIC ...

Page 30: ...27 WIRING DIAGRAM FOR MODEL CUV 100 WITH XG UV SERIES HOODS ...

Page 31: ...28 WIRING DIAGRAM FOR GAD 100 CONTROLLERS WITH GFBD DAMPERS ...

Page 32: ...29 WIRING DIAGRAM FOR GAD 100 CONTROLLERS WITH NO DAMPER ...