4

PRINCIPLES OF OPERATION

UV Lamps

Systems incorporating UV lamps will have the extra added

benefit of further break down of grease, in some cases down

to CO2, H20, and base minerals. The processes called

“Photolytic Oxidation”, and “Ozonolysis” are the drivers

behind keeping your ducts clean and free of containments

for much greater durations over conventional kitchen exhaust

systems not utilizing the UVC technology. The processes

break down, and condition grease dramatically reducing its

ability to burn or in some cases even combust. For proper

UV operation, the hoods must be maintained in good working

order. UV Lamps will accumulate a light gray dust on them

that will have to be periodically wiped off from below. Duct

work will have to be inspected in accordance with NFPA-96

or local guidelines, though frequency of duct cleanings will

be dramatically reduced.

Important Notice:

Never operate your Ventilator without

the XG Extractors in place. The XG extractors are UL 1046

Flame Exposure tested to protect you’re your system from

penetration of fire into the exhaust duct. The XG Extractor is

also a light attenuation barrier to remain in place at all times

during the use of your UV system.

Cleaning

At the end of each cooking day the fan is to be turned off and

the XG Extractors are to be safely removed from the hood

and cleaned. The

“XG” Extractors

can be washed either

in a dishwasher or soaked and rinsed off. The XG filter has

a unique dual hinge design that will allow the extractor to

be opened so its internal components are accessible for

cleaning. Periodic internal scrubbing of the extractors may

be necessary in lines servicing busy kitchens, or lines using

sugary sauces or bastings.

The

UV lamps

will develop a coating of dust, and sometimes

debris that will have to be periodically wiped away to

optimize the UVC Systems performance. The lamps should

be inspected weekly once the filters are removed. When

necessary, the lamps can be cleaned from below by carefully

wiping the bulbs with a wet cloth using some mild detergent.

A maintenance rotation should be initiated at the point of

start up by a Gaylord Industries certified Service Agent to

address any maintenance, or repair issues that may be

required.

Fire Protection

NFPA-96 Requires the use of Surface Fire Protection

(Duct, Plenum, Surface/Appliance)

on all hoods. It is these

systems that are the first line of defense against equipment

fires. Refer to the fire extinguishing systems owner’s manual

for operation and maintenance instruction of for these

systems.

The

XG-GFBD

Series ventilator incorporates a fire /

balancing damper in stalled in the duct collar to protect your

ducts, fans, and roof tops from the threat of fire in the event

your primary fire protection system fails to extinguish the fire.

In the event of a fire when the thermostat reaches its set

point of 325°F, the power to the hood will be cut allowing the

dual blade damper to spring shut sealing the duct entrance

and keeping the fire contained in the plenum, where it can

be properly managed. Exhaust dampers are an excellent

way to protect your roof top and un-maintained grease ducts

from the threat of fire.

The hood may also be supplied without a fire damper, which

would be designated by either the suffix

“ND”

or

GBD

in the

model number.

GBD

designates a balancing ONLY damper.

Refer to the nameplate on the hood for the exact model

number designation.

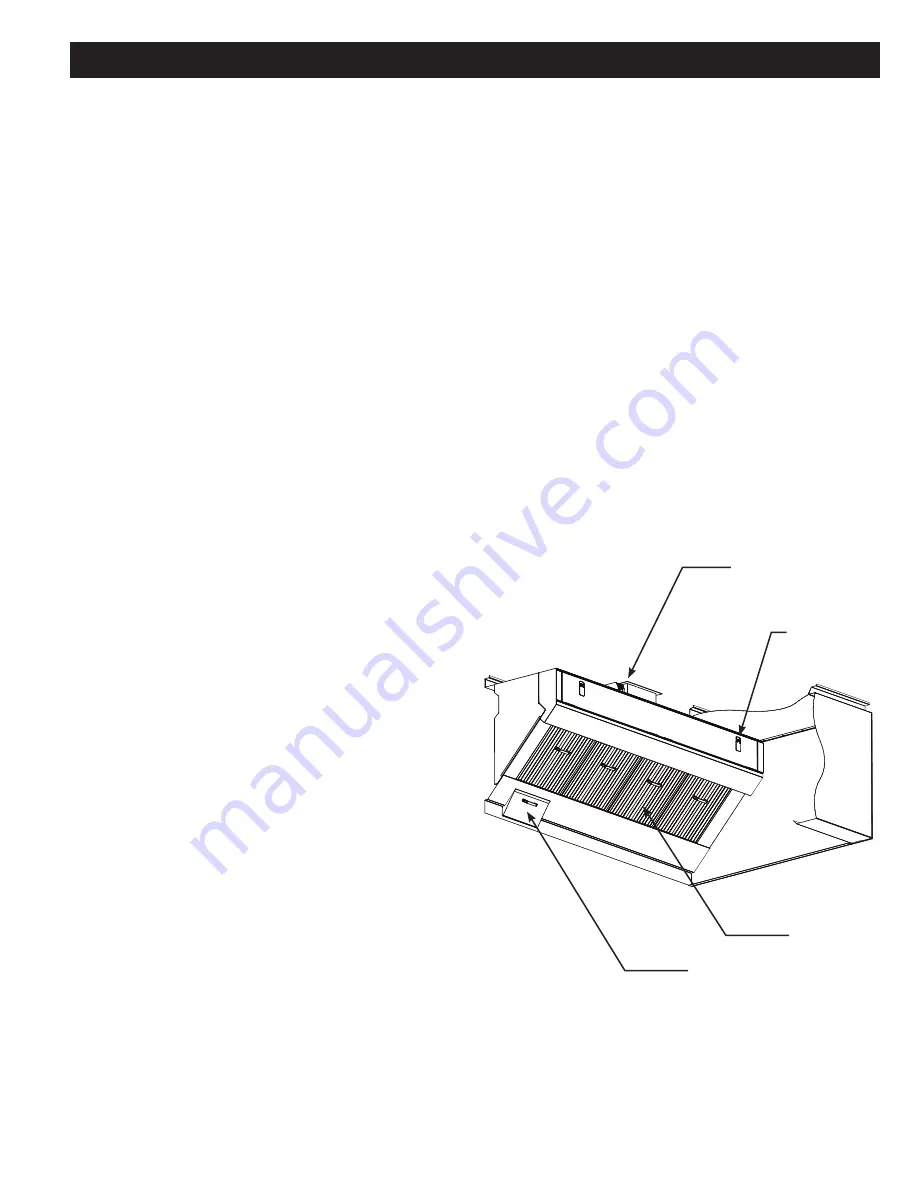

GFBD Damper

(Shown)

UV Access

(Keyed Latch)

XG Extractor

Grease Drawer

FIGURE 7

XG-UV-GFBD BDL

Summary of Contents for XG-BDL

Page 13: ...10 GFBD EXTERNAL WIRING MULTIPLE SECTION FIGURE 16B GFBD External Wiring Diagram ...

Page 29: ...26 UV HOOD WIRING BOARD SCHEMATIC ...

Page 30: ...27 WIRING DIAGRAM FOR MODEL CUV 100 WITH XG UV SERIES HOODS ...

Page 31: ...28 WIRING DIAGRAM FOR GAD 100 CONTROLLERS WITH GFBD DAMPERS ...

Page 32: ...29 WIRING DIAGRAM FOR GAD 100 CONTROLLERS WITH NO DAMPER ...