Overview

This Operating Manual covers information on safety and

cautions. Please read the relevant information carefully

and observe all the

Warnings

and

Notes

strictly.

Warning

To avoid electric shock or personal injury, read the

“Safety Information”carefully before using the Meter.

G9204 are AC clamp multimeters(hereafter referred

to as "the Meter") with remarkable features: versatile

functions, stable operation, low power consumption and

ergonomic structural design. They can measure AC/DC

voltage, AC current, resistance,diode, continuity, frequency

and temperature,etc.

Except where noted, the descriptions and instructions in

this Operating Manual apply to both the

G9204.

Unpacking Inspection

Open the package case and take out the Meter. Check the

following items carefully for any missing or damaged part:

Item

Description

Qty

1

2

3

4

5

In the event you find any missing or damaged part, please

contact your dealer immediately.

Operating Manual

Test Leads

Point Contact Temperature Probe

9V Battery (NEDA 1604, 6F22 or 0006P)

(installed inside the Meter)

Vinyl Bag

1 pc

1 pair

1 pc

1 pc

1 pc

Safety Information

This Meter complies with the standard IEC61010: Pollution

Degree 2, Overvoltage Category (CAT. II 600V / CAT III

300V) and Double Insulation.

CAT II: Local level, appliance, PORTABLE EQUIPMENT

etc., with smaller transient voltage overvoltages than CAT. III

CAT. III: Distribution level, fixed installation, with smaller

transient overvoltages than CAT. IV.

Under the influence of Radiated, Radio-Frequency Electro

-magnetic Field phenomenon,the captioned model may

malfunction and can self-recover after the test.

Use the Meter only as specified in this operating manual,

otherwise the protection provided by the Meter may be

impaired.

In this manual, a

Warning

identifies conditions and acti

-ons that pose hazards to the user, or may damage the

Meter or the equipment under test.

A

Note

identifies the information that user should pay

attention to.

To avoid possible electric shock or personal injury,

and to avoid possible damageto the Meter or to the

equipment under test, adhere to the following rules:

Check for the lever is in good condition when

measuring AC current.

Must center the wire (conductor) within the trans

-former jaw.

Before using the Meter inspect the case. Do not

use the Meter if it is damaged or the case (or part

of the case) is removed. Look for cracks or missing

plastic. Pay attention to the insulation around the

connectors.

Inspect the test leads for damaged insulation or

exposed metal. Check the test leads for continuity.

Replace damaged test leads with identical model

number or electrical specifications before using

the Meter.

Do not apply more than the rated voltage, as marked

on the Meter, between the terminals or between

any terminal and grounding.

The rotary switch should be placed in the right

When the Meter is working at an effective voltage

over 60V in DC or 42V rms in AC, special care

should be taken for there is danger of electric shock.

Warning

position and no any changeover of range shall be

made when measurement is conducted to prevent

damage of the Meter.

Use the proper terminals, function, and range for

your measurements.

When using the test leads, keep your fingers behind

the finger guards.

Disconnect circuit power and discharge all high-

voltage capacitors before testing.

To avoid harm to you or damage to the Meter from

electric shock, please do not attempt to apply higher

than 600V between the terminals and grounding.

Replace the battery as soon as the battery indicator

appears. With a low battery, the Meter might

produce false readings that can lead to electric

shock and personal injury.

When servicing the Meter, use only the replacement

parts with the same model or identical electrical

specifications.

The internal circuit of the Meter shall not be altered

at will to avoid damage of the Meter and any accident.

Soft cloth and mild detergent should be used to

clean the surface of the Meter when servicing. No

abrasive and solvent should be used to prevent

the surface of the Meter from corrosion, damage

and accident.

Turn the Meter off when it is not in use and take

out the battery when not using for a long time.

Constantly check the battery as it may leak when

it has been using for some time,replace the battery

as soon as leaking appears. A leaking battery will

damage the Meter.

Do not use or store the Meter in an environment

of high temperat ure, humidity,explosive, inflamm

-able and strong magnetic field. The performance

of the Meter may deteriorate after dampened

International Electrical Symbols

AC (Alternating Current)

DC (Direct Current)

AC or DC

Grounding

Double Insulated

Fuse

Low Battery Indication

Continuity Test

Diode

Conforms to Standards of European Union

Warning. Refer to the Operating Manual

Risk of Electric Shock

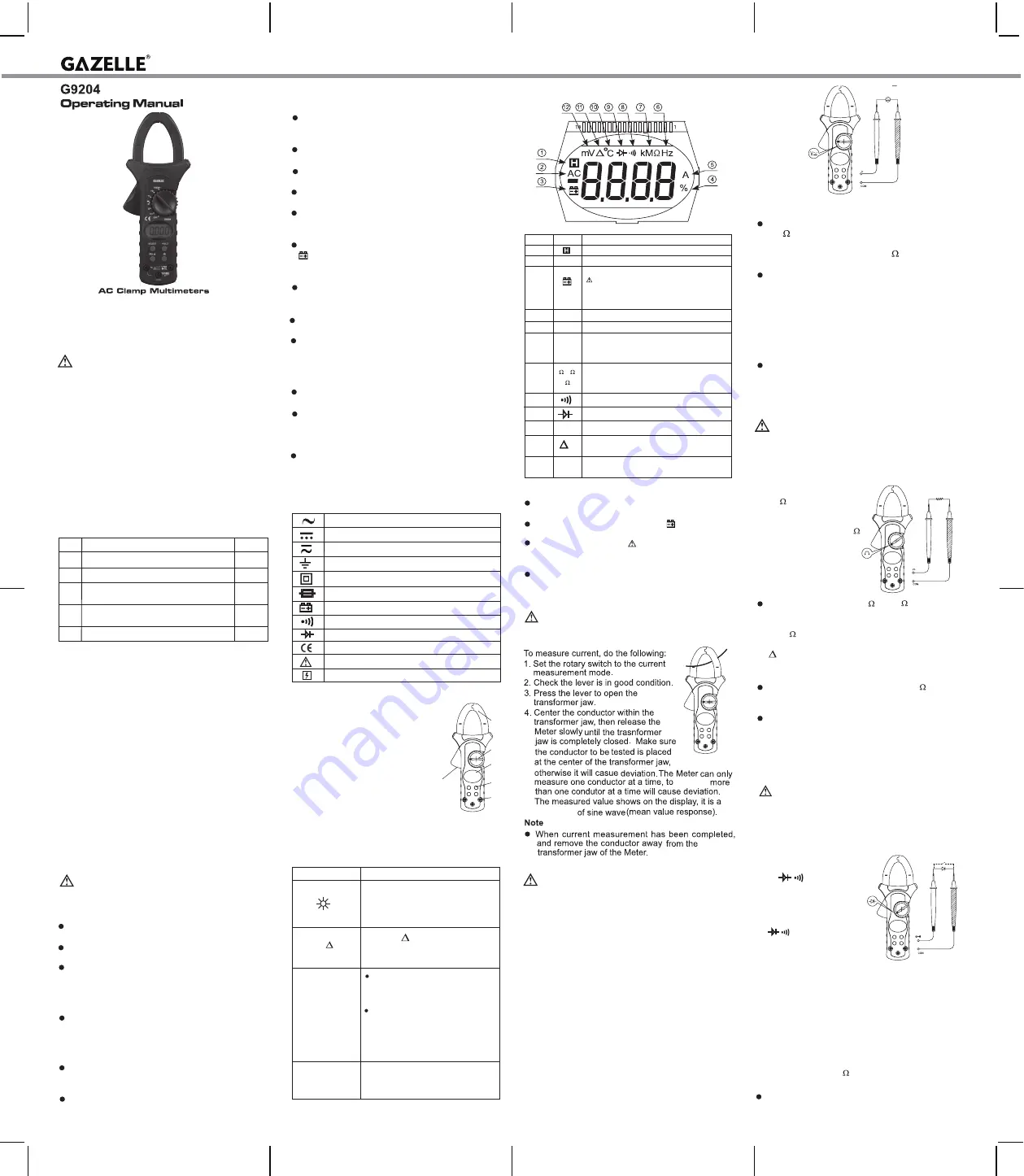

The Meter Structure

(See Figure 1)

Figure 1

1.

2.

3.

4.

5.

6.

Transformer Jaw designed to pick

up the AC current flowing through

the conductor.

Rotary Switch.

LCD Display.

Function Buttons

Input Terminals

Lever. Press the lever to open

the transformer jaws. When the

pressure on the lever is released,

the jaws will close.

1

2

3

4

5

6

Below table indicated for information about the functional

button operations.

Functional Buttons

Description

Button

Turn the display backlight on and off.In

order to avoid the hazard arising from

mistaken readings in insufficient light or

poor vision, please use Display Backlight

function.

REL

Press

REL

to enter and exit the REL

mode in any measuring mode except in

frequency and duty cycle,the Meter beeps.

Switches between AC voltage and DC

Voltage measurement, and continuity

and diode measurement; the Meter

beeps.

SELECT

HOLD

Press

HOLD

to enter and exit the

Hold mode in any mode, the Meter

beeps.

When it is under sleep mode, press

to activate the Meter at the effective

measurement range,e.g. continuity

buzzer. Auto power off feature will be

disabled until Switching off and turning

on the Meter again.

Display Symbols

(See Figure 2)

Figure 2

Number

Description

1

2

3

4

5

AC

Symbol

%

Data hold is active.

Indicator for AC Voltage.

The battery is low.

Warning: To avoid false readings, which

could lead to possible electric shock or

personal injury, replace the battery as soon

as the battery indicator appears.

Percent: Used for duty cycle measurements.

A

Indicator for AC current

Hertz. The unit of frequency.

Kilohertz. 1x 10

3

or 1000 hertz.

Megahertz. 1x10

6

or 1,000,000 hertz.

Hz, kHz,

MHz

Ohm. The unit of resistance.

kilohm. 1 x 10

3

or 1000 ohms.

Megaohm. 1x10

6

or 1,000,000 ohms.

,

k

,

M

6

7

8

9

10

11

12

V, mV

The continuity buzzer is on.

Test of diode

Centigrade. The unit of temperature.

The relative value mode is on to display

the stored value minus the present

Volts. The unit of voltage.

Millivolt. 1 x 10

-3

or 0.001 volts.

o

C

Measurement Operation

Figure 3

A. Measuring AC Current

(See Figure 3)

Warning

The measurement value obtained is wrong if testing

two or more current conductors at the same time.

Make sure the Sleep Mode is not on if you found there

is no display on the LCD after turning on the Meter.

Make sure the Low Battery Display is not on;

otherwise false readings may be provided.

Pay extra attention to the symbol which is located

besides the input terminals of the Meter before carrying

out measeurement.

Make sure you are in the proper measurement range

before carrying out measurement.

measure

RMS value

B. Measuring DC Voltage

(See Figure 4)

Warning

To avoid harm to you or damage to the Meter from

electric shock, please do not attempt to measure

voltages higher than 600V although readings may

be obtained.

To measure DC voltage, connect the Meter as follows:

1. Insert the red test lead into the

V

terminal and the

black test lead into the

COM

2. Set the rotary switch to

DC voltage measurement

mode.

Figure 4

Red

Black

3. Connect the test leads across with the object

being measured.

The measured value shows on the display.

In each range, the Meter has an input impedance of

10M .This loading effect can cause measurement

errors in high impedance circuits. If the circuit imped

-ance is less than or equal to 10k , the error is

negligible (0.1% or less).

When DC voltage measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test, and remove the testing leads

away from the input terminals of the Meter.

Note

AC Voltage measurement is an auto ranging measure

-ment mode.

Follow the same procedure as the DC Voltage Meas

-urement mode. When you using UT206A to carry

out the measurement, use

SELECT

button to switch

between ACV and DCV.

Note:

C. Measuring AC Voltage

(See Figure 4)

D. Measuring Resistance

(See Figure 5)

Warning

To avoid damages to the Meter or to the devices

under test, disconnect circuit power and discharge

all the high-voltage capacitors before measuring

resistance.

To measure resistance, connect the Meter as follows:

1. Insert the red test lead into

the terminal andthe

black test lead into the

COM

terminal.

2. Set the rotary switch to .

3. Connect the test leads

across with the object

being measured.

The measured value shows

on the display.

Note

The test leads can add 0.1 to 0.3 of error to

resistance measurement.To obtain precision readings

in low-resistance measurement under the range of

400.0 , short-circuit the input terminals beforehand,

using the relative measurement function button

REL

to automatically subtract the value measured

when the testing leads are short-circuited from the

reading.

Red

Black

Figure 5

For high-resistance measurement (>1M ), it is

normal to take several seconds to obtain a stable

reading.

When resistance measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test, and remove the testing leads

away from the input terminals of the Meter.

E. Testing for Diodes and Continuity

(See Figure 6)

To avoid damages to the Meter or to the devices

under test, disconnect circuit power and discharge

all the high-voltage capacitors before testing for

continuity.

Warning

To test for diodes and continuity, connect the Meter as

below:

Figure 6

Red

Black

1. Insert the red test lead into

the terminal and the

black test lead into the

COM

terminal.

2. For diode test

a. Set the rotary switch to

.

b. For forward voltage drop

readings on any semicon

-ductor component, place the

red test lead on the component’s anode and place

the black test lead on the component’s cathode.

The measured value shows on the display.

3. For continuity test:

a. Press

SELECT

to switch between Diode and Contin

-uity test.

b. Connect the test lead to the two end of the circuit

under test.

c. The buzzer sounds if the resistance of a circuit under

test is less than 100 .

In a circuit, a good diode should still produce a

Note

terminal.