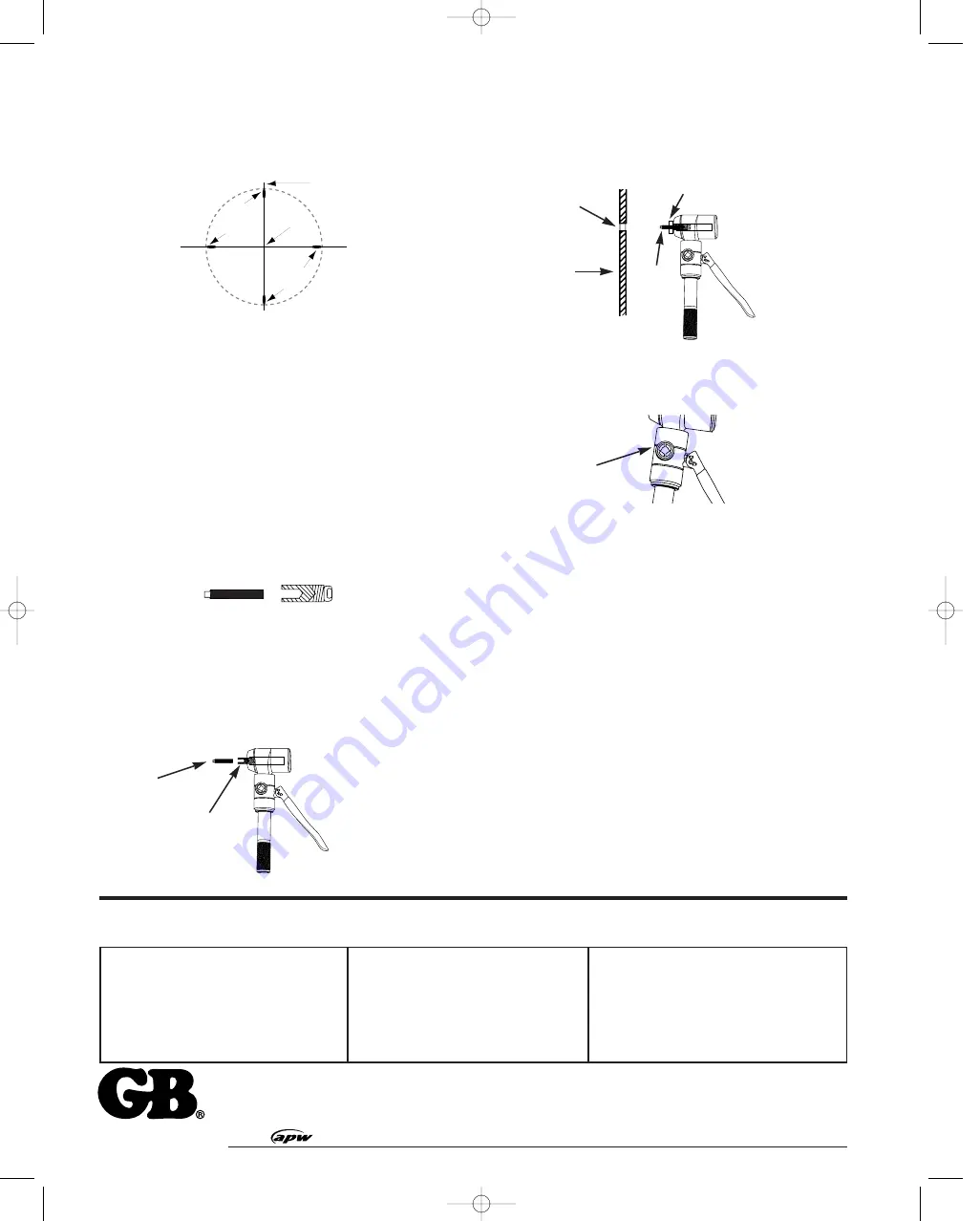

Drilling Guide Holes

1. Mark the center position, drill a

1

⁄

8

” pilot hole. Enlarge

the hole with a

7

⁄

16

” drill to provide pull rod clearance.

a. If working to close tolerances, mark the center

position by scribing cross lines shown in Figure 1.

b. When assembling the punch to the pull rod, align

the cross marks with the four marks on the outer

die surface.

NOTE: If pre-punched knockouts are already in

the desired location, drilling a guide hole is not

required.

2. For larger holes

3

⁄

4

” to 2

1

⁄

2

”, the

1

⁄

2

” punch is used to

make the guide hole.

Punching

1

⁄

2

” Holes

1. Thread the pull stud into the pull stud adapter end until

firmly seated. (Figure 2)

NOTE: The pull stud and pull stud adapter are only

used with the

1

⁄

2

” punch. The

1

⁄

2

” punch is used to make

guide holes for larger punch sizes.

2 Attach the pull stud adapter to the cylinder by inserting

the pull stud adapter into the plunger opening and

threading until the pull stud extends beyond the end of

the cylinder. (Figure 3)

3. Slide the

1

⁄

2

” die over the pull stud, flat side toward

the cylinder.

4. Insert the pull stud through the guide hole (Figure 4).

Attach the

1

⁄

2

” punch to the pull stud. Turn the punch

until it is completely threaded onto the pull stud.

5. Close the pump release valve by turning it clockwise

(Figure 5). Hold the punch set in position, work the pump

handle until the punch completely penetrates the metal.

6. Remove the punch set from the hole. Turn pump release

valve counterclockwise to open. The cylinder will retract

and the slug must be removed from between the punch

and die.

Punching

3

⁄

4

” through 2

1

⁄

2

” Holes

1. Drill a pilot hole(

7

⁄

16

”) install the

1

⁄

2

” punch and make

guide hole. See

Punching

1

⁄

2

” Holes.

2. Remove the

1

⁄

2

” punch and die set. Also remove the

pull stud and pull stud adapter.

3. Attach the pull rod (KPR7520) to the cylinder by inserting

the rod into the plunger opening and threading until the

pull rod extends beyond the end of the cylinder.

4. Select the punch set needed. Slide the die over the

pull rod.

5. Place the pull rod into the

1

⁄

2

” guide hole, thread the

punch onto the pull rod. Be sure the pull rod extends

beyond the punch.

6. Operate the hand punch until the punch penetrates the

metal. Open the punch release valve. Remove the slug.

Note: To avoid excessive wear and tear on the pull rod threads during

punching, center the guide hole accurately enough so that the pull rod

does not rest against the metal edge of the guide hole. Also, be sure

that all points of the punch are in uniform contact with the metal surface

when starting to punch.

WARRANTY: GB ELECTRICAL, INC. warrants its

product against defects in workmanship and materials

for 1 year from date of delivery to user. Warranty does

not cover ordinary wear and tear, abuse, misuse,

overloading, altered products or use of improper fluid.

WARRANTY RETURN PROCEDURE: When question

of warranty claim arises, send the unit to the nearest GB

Authorized Service Center for inspection, transportation

prepaid. Furnish evidence of purchase date. If the claim

comes under the terms of our warranty the Authorized

Service Center will REPAIR OR REPLACE PARTS

AFFECTED and return the unit prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only repairs

performed by an Authorized Service Center displaying

the official GB Authorized sign are backed with full

factory warranty. Contact GB Electrical (414)352-4160

for the name of the nearest GB Authorized

Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL Service Center. The GB

ELECTRICAL Service Center will provide complete and prompt service on all GB ELECTRICAL products.

Gardner

Bender

6101 N. Baker Road, Milwaukee, WI 53209 • Phone: (414) 352-4160 • FAX (414) 352-2377

RPS-0129 4/98

A unit of Tools and Supplies

Pump Release Valve

Figure 5

Figure 4

Figure 3

Pull Stud

Adapter

Pull Stud

Pre-drill

7

⁄

16

” Hole

Metal

Box

Dotted line

Indicates

Knock-Out

Die

Cross Lines

6" Long

Lines On

Die Line

Up With

Cross Lines

Center

Drilling of Guide Hole

Figure 1

Pull Stud

KPS50

Pull Stud

Adapter

KSA50

Figure 2

Draw

Stud

Die

RPS-0129 3/29/00 11:11 AM Page 2