Page 4 - 3

Installation

F - 160 CE Operation and Maintenance Manual

© GBC Films Group April 2000

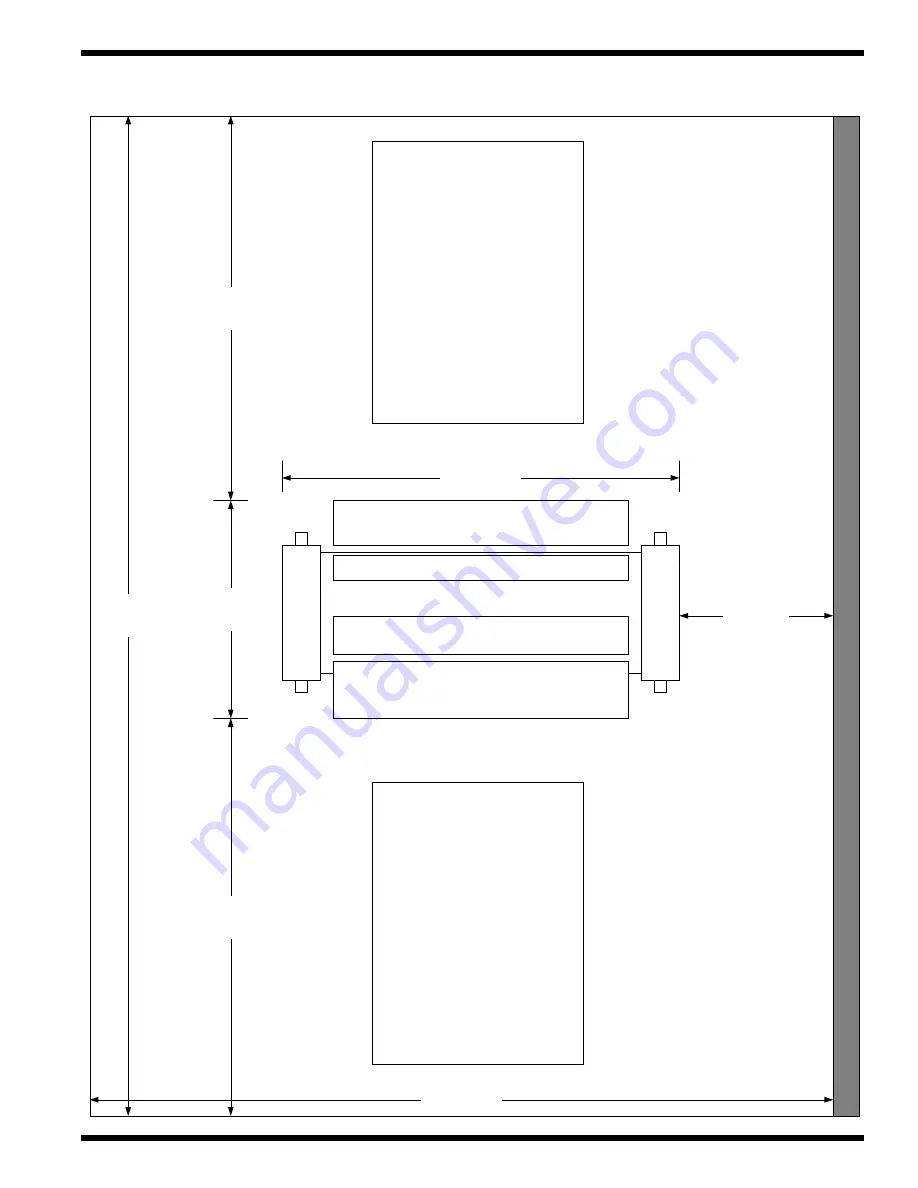

Figure 4.1.1 Suggested Floor Layout

4' x 6' ( 1.22 m x 2m )

Work table on wheels

Table height

35-3/4" ( .94 - .95m )

4' x 6' ( 1.22 m x 2m )

Work table on wheels

Table height

35-3/4" ( .94 - .95m )

3' ( 1 m)

13' ( 4 m)

20'

( 6 m )

82.5"

( 209 cm )

8.4'

( 2.57 m )

38"

( 96 cm )

8.4'

( 2.57m )