5

USP 13

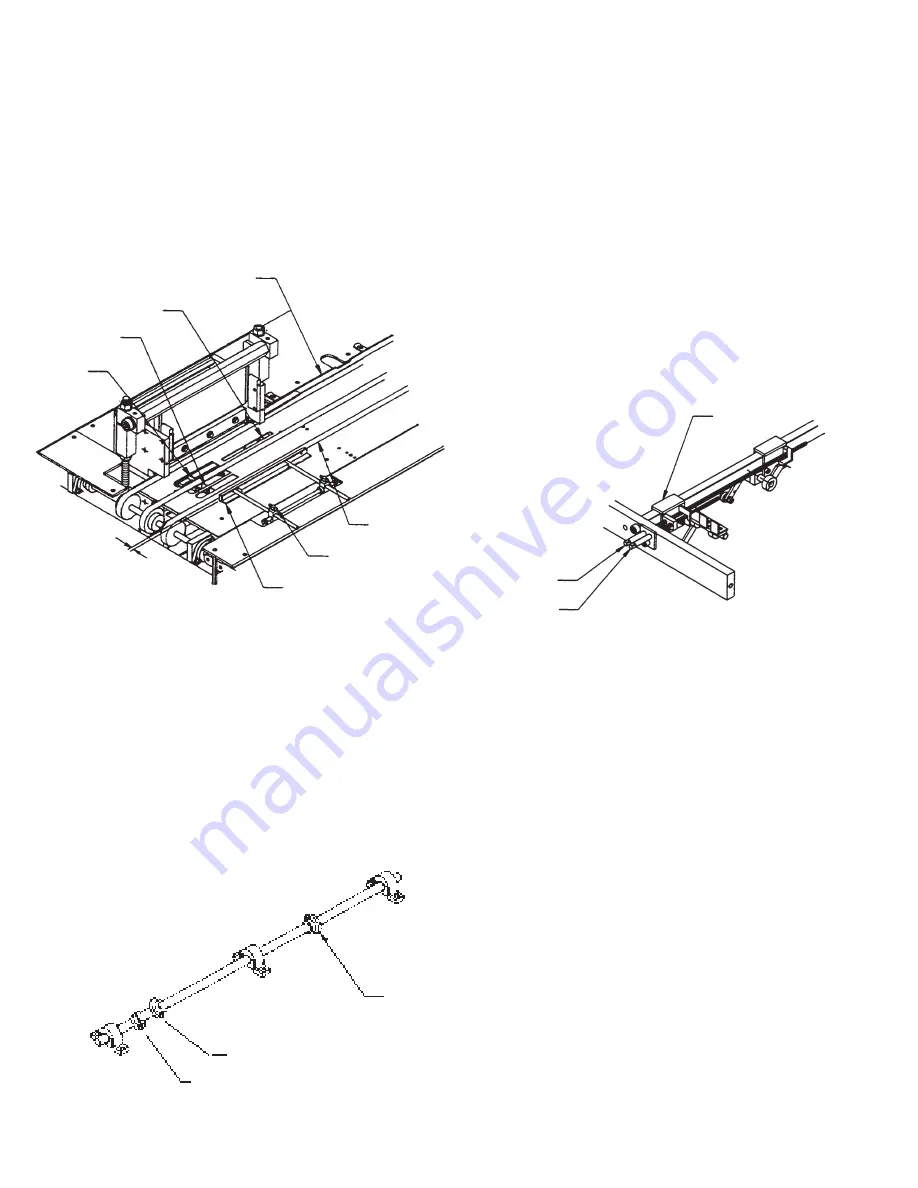

SET-UP INSTRUCTIONS:

After the punching die is properly installed, position the

back gauge rail (#108, Figure 7) slightly ahead of the

punch die back gauge so that a piece of paper can slide

freely into the throat of the die and not hit the back

gauge of the punch die.

Cam (#37) activates the rear jogger (#34) and the side

jogger (#29). Adjust the cam so that when the longest

punch pin appears in the throat of the punching die, the

rear jogger (#34) should have just reached the full

vertical position.

Cam (#44) activates the front stop (#26). Adjust the cam

so that when the front stop finger (#100) reaches the full

vertical position, the side jogger (#29) starts its cycle

inward.

Loosen locking bolt (S40) under front bearing block

(#93, Figure 9) prior to setting registration.

Position the front stop (#26) so it is in its full up

position. Place a sample sheet of paper against the front

stop and punch paper. If the punch pattern is not

centered on the paper, adjust the front stop by turning

the front stop adjustment rod (#117) until the punch

pattern is centered. Once the front stop is set properly,

adjust the rear jogger so that it touches the paper. To do

this, turn the rear jogger stop adjustment (#118).

SETTING REGISTRATION

CONVEYOR SYSTEM

Cycle this machine manually by turning the hand wheel

until the rear jogger is in its full up position. Install side

jogger (#29) to slightly buckle a sheet of paper. Lock in

place with T-knobs (#248, Figure 7).

Adjust the outer transfer belt (#255, Figure 7) so that it

sets about 1/4” (.25) away from fully jogged side jogger.

When registration is set, lock in place by tightening

locking bolt. (S40, Ref. Page 30).

Figure 7

Figure 9

Figure 8

248

29

.25

26

34

100

108

OUTER BELT

117

118

93

44

37

43