The TDS set point set at 140 for shut off. You can change the shut off point to the lever of TDS you desire.

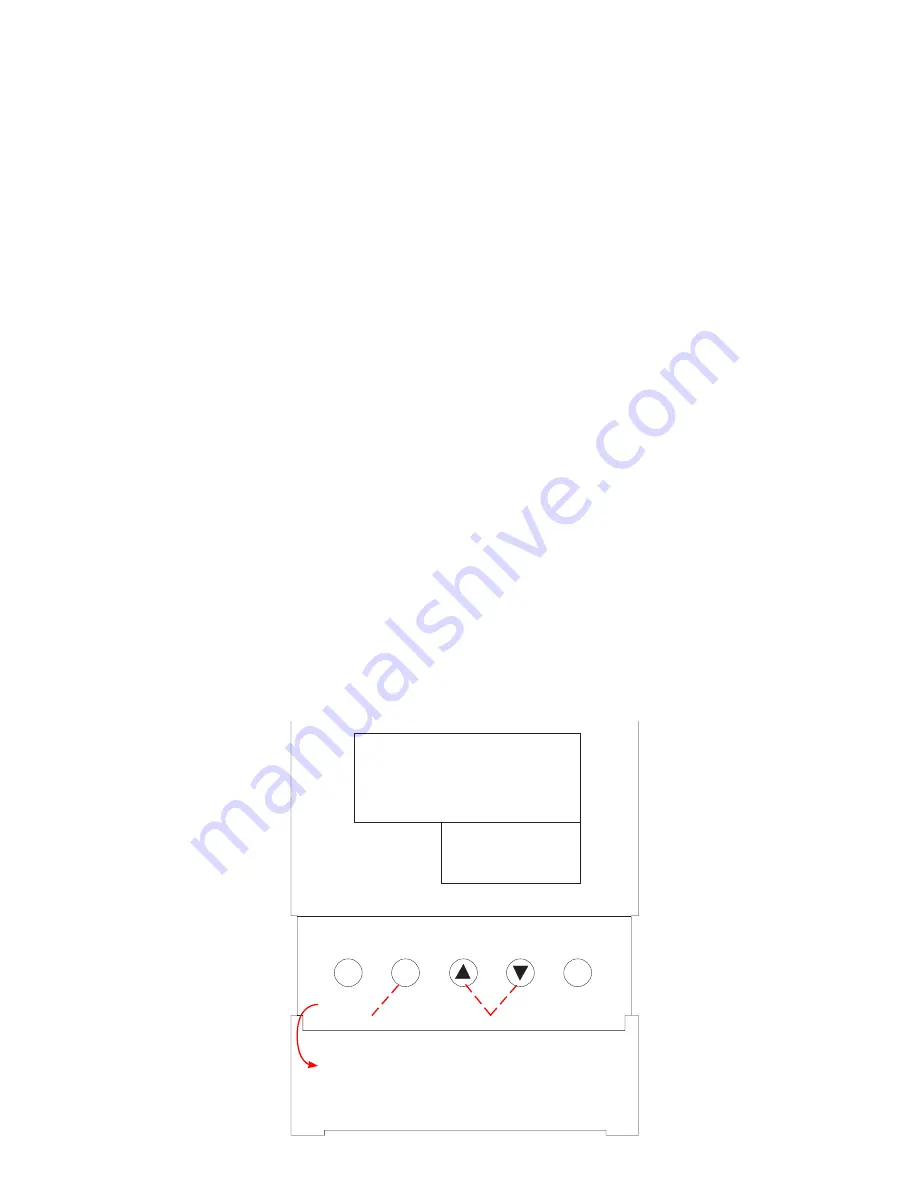

1. To change the TDS controller set point start by opening the door on the TDS controller.

2. CP1 is your low range set point. To change it push the CAL button ( 1 ) once.

3. Verify the monitor displays CP1. The factory setting will display as 140 TDS.

4. Push the up or down button ( 2 ) on the TDS controller to adjust the TDS low range to your desired level.

5. CP2 is your high range set point. To change it push the CAL button ( 1 ) again.

6. Verify the monitor displays CP2. The factory setting will display as 155 TDS. Typically it is set 15 above low range.

7. Push the up or down button ( 2 ) on the TDS controller to adjust the TDS low range to your desired level.

8. To get out of verifying/programming mode, you need to push the CAL button ( 1 ) until the monitor displays current water

temperature and current TDS level in tank.

9. Close the cover to the small black box to protect the buttons from harm.

NOTE:

TDS controller must be calibrated every 3 months to maintain proper calibration level.

1. Use the supplied hand held TDS meter. Make sure the TDS meter is set to test a 0.7 factor (442). Follow the “Hand Held TDS

Meter” on page 11 for instructions on how to use and adjust the supplied hand held TDS meter.

2. Check the outgoing TDS levels from the unit in question.

3. If the TDS levels do not coincide, proceed to step 4.

4. Flip open the door on the front of the TDS meter.

5. Press and hold the CAL button ( 1 ) until a beep is heard and the display read CAL.

6. Press UP or DOWN ( 2 ) to achieve the desired reading.

7. Once the display matches the desired level, press the CAL button (1) again to set it.

8. Close the cover to the small black box to protect the buttons from harm.

MODE

CAL

SET

˚C/ ˚F

ALARM

ON/OFF

2

1

CHANGE THE TDS CONTROLLER SET POINTS

CALIBRATING TDS CONTROLLER

PAGE 10