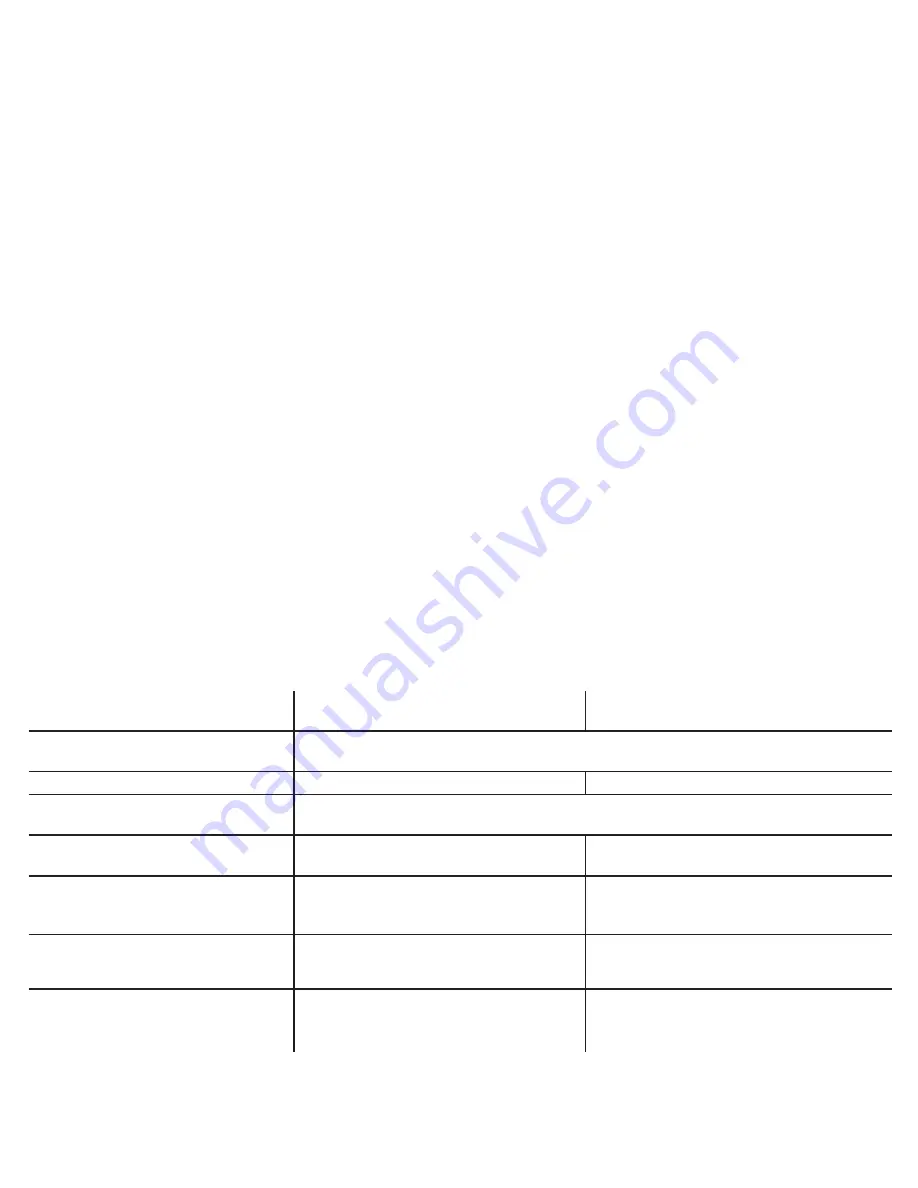

TROUBLESHOOTING OVERVIEW:

SYMPTOM

OR STATE

LIKELY

CAUSE

REMEDY

OR CORRECTION

Yellow lever on system is in

“Emergency By-Pass” position.

Consult previous shift log. Verify Service has been called.

Minor Leak around system.

Filter seals need replacement.

Call for service.

Major leak or flooding.

1. Turn circuit breaker off. 2. Place system in Emergency Hard Bypass, see below. 3.

Call for Service.

Less than 35 psi reading on the

“System Delivery” Gauge.

No electrical power or insufficient City

Water Pressure to system.

Perform Steps 2 through 4.

Coffee Urn short batching or

“System Delivery” Gauge reads less

than 35 psi.

Filters plugged and need replacement.

Call for service (If above 35 psi, problem

may be with POU equipment).

System INLET Gauge reads 0 psi.

Check water supplied to location

Verify City Feed is open; still having

issues. Call for Plumber.

TDS levels do not stay at factory

levels

Too High TDS

Too Low TDS

Call for Service.

Out of Formula. Replace Formula by calling

GC Water 805.484.1589.

Step by step troubleshooting guide is designed for the store operator to avoid unnecessary service calls and expenses. Do

not hesitate to call for Technical Support if using this guide fails to fix the problem.

Please have the results of these step by step

checks ready before you call. Often the symptom or problem is not with the system itself, but with the power to the building or

city water pressure to the system. If no water is available to one POU (espresso or brewer) this is a sure sign the problem is not

with the system, but rather with the equipment the system supplies. Do not operate espresso machine or brew coffee during

troubleshooting procedures, equipment damage may result.

Y-STEP INSTRUCTIONS:

1. Check the system pressure gauge reading. If the pressure reading is normal, (35-60 psi), then there is no immediate problem

with the system. If the pressure moves below 35 psi or is at 0 psi, this means the city water pressure to system is too low

or the electric and/or water is turned off to system. See step 2.

2. Verify if power monitor is on. Check the system digital monitor to see if it is turned on. If not, push in the green button. If

the system now has electrical power, go to Step 3. If not, check to see if yellow switch is on; if not, or you had to plug in the

system, reset store electrical circuit breaker. Once power is returned, see step 3.

3. Check that water to the building is running by turning on a sink faucet. If water is running, check all water valves to the system

are turned on fully. If both steps show water is on and available to system, see step 4. If water to the system was not available

and is now restored to the system, wait 5 minutes for delivery pressure (above 35 psi) to be restored and for system pump

to begin running normally. See step 4.

4. If steps 1-3 fail to get the system producing water to the POU, call your Store Facility Service Center or GC Water immediately.

To supply water temporarily to the POU (points of use) (brewer, espresso, etc.,) bypass the system which will send city water

to the system instead of the system water. Turn the system into bypass by turning the yellow bypass handle on the front

faceplate from off

to the bypass position.

NOTE:

Tank will not refill while in bypass. System Pressure will read zero psi.

Do not place the system into “EMERGENCY BYPASS MODE” without informing the Store Management immediately.

TROUBLESHOOTING GUIDE

PAGE 15