Page 19 of 28

M434/500 Prototype Commissioning Manual

PN W453101Rev- Nov-02-1998

Test Attachments

There is little calibration required to set up fly’s and jibs. The most likely requirement is for a deflection

correction. The deflection correction may be applied to each attachment by calibrating with the bdc

command. Do not calibrate bdc unless unloaded tests are complete and satisfactory, and the main boom

radius accuracy is correct.

The angular offset of the fly is normally the dimension that requires change in the capacity chip during

testing. Since all fly’s fit to the boom head using the same physical attachments, the offset angle of all

fly’s with the same offset may be modified at the same time.

Test the longest fly at all of it’s offsets before making corrections to the capacity chip and continuing with

other attachment testing.

Data collected from the main boom calibrations may be added to the capacity chip at this time also.

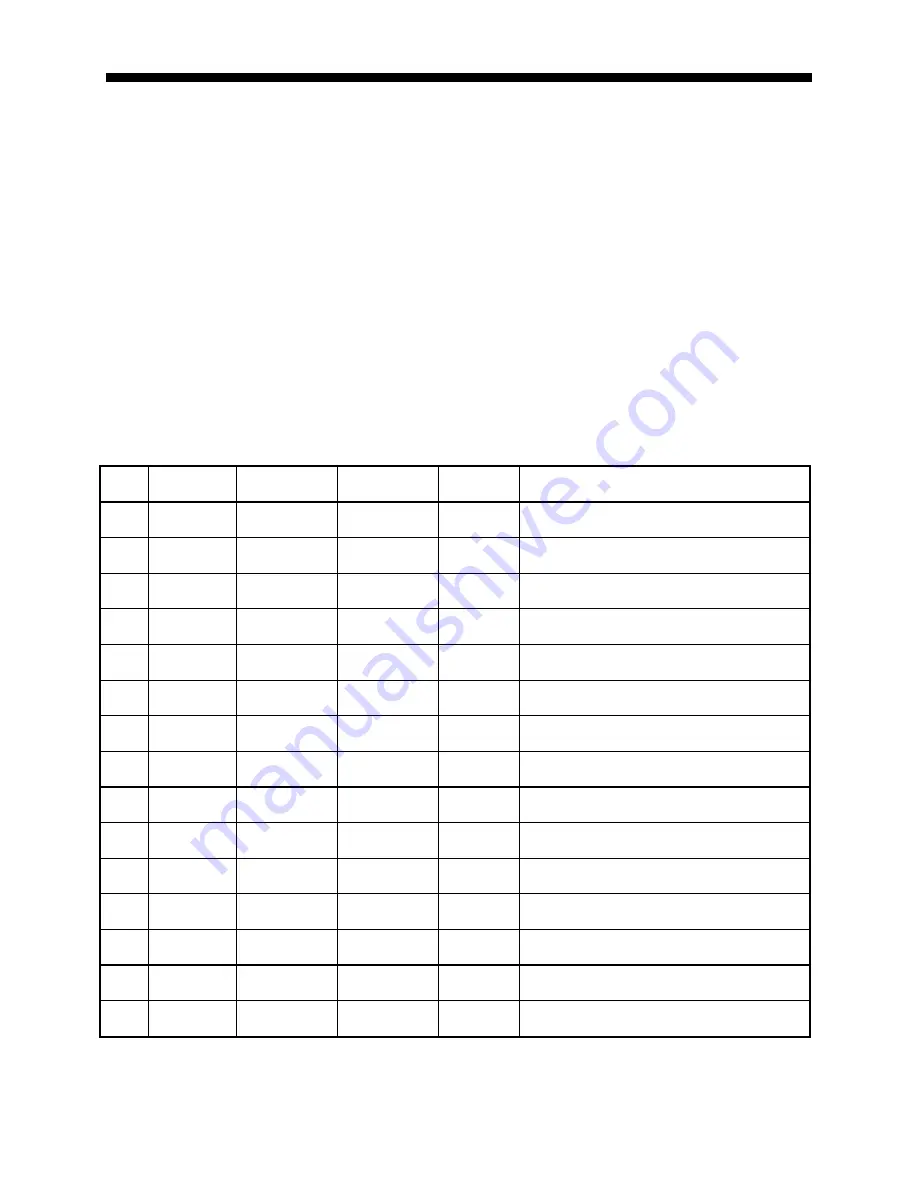

Test sequence

Start testing with the longest attachment at the straightest offset angle.

It is a good idea to check the length and vertical offset dimensions of the attachment with a tape before

commencing tests. If necessary correct the values of these in the capacity chip.

The following tests should be done on each attachment:

Test Fly

Offset

Boom

Length

Boom

Angle

Load Comments

1*

Straight

Retracted

0

Hook

Establish that fly length is correct

through radius accuracy (+/-0.2ft)

2*

“

“

>60

“

Establish that fly offset angle is correct

through radius accuracy (+/-0.2ft)

3*

“

Extended

>60

“

Establish Fly moment accuracy (-0 to

+0.2lbs*1000)

4* “ Retracted

>60

>50%

Capacity

Attachment deflection correction

Note the bdc “F” factor

5

“

“

Low to High

3-angles

“ Load

Test

6 “

Mid-Range

“ “

Load

Test

7 “ Fully

Extended

“ “

Load

Test

8* First

Offset

Retracted

>60

Hook

Establish that fly offset angle s correct

through radius accuracy (+/-0.2ft)

9

“

“

Low to High

3-angles

“ Load

Test

10 “

Mid-Range “

“

Load

Test

11 “ Fully

Extended

“ “

Load

Test

12* Second

Offset

Retracted

>60

Hook

Establish that fly offset angle is correct

through radius accuracy (+/-0.2ft)

13

“

“

Low to High

3-angles

“ Load

Test

14 “

Mid-Range “

“

Load

Test

15 “ Fully

Extended

“ “

Load

Test

•

Indicates that an adjustment to the capacity chip data may be required following these checks.