www.GCCworld.com LABEL EXPRESS / DECAL EXPRESS User Manual

71

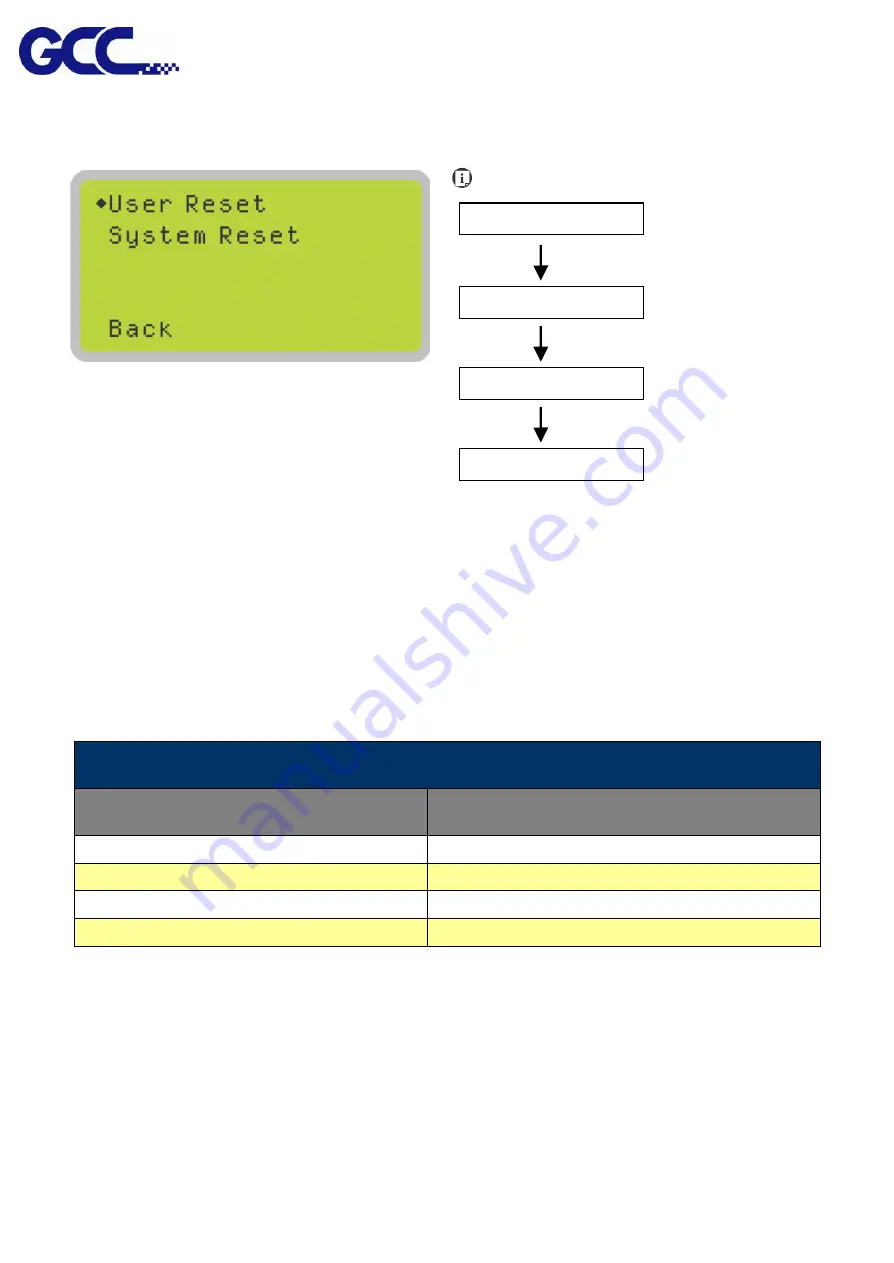

Machine Setting- Reset Page

The Reset Page allows you to reset all changes made to the LaserPro Spirit Series Machine

Settings Page to their default settings. This does not affect the settings saved to an image

file on the computer. The <User Reset> setting will set all settings back to default. After any

firmware updates, you must use the <System Reset> setting (your previous settings are

saved).

•

User Reset (a confirmation will pop up, press Enter to confirm and continue)

•

System Reset (a confirmation will pop up, press Enter to confirm and continue)

Reset Page

Relevant Buttons

Function

F1 (Back)

Back to previous page

/

Directional

Scroll through the menu selections

Enter

Perform the selection

Start / Stop

Back to Main Work Page

Main Work Page

Functions Page

press F4

Machine Setting Page

Select<

Machine

Setting

>from the menu

Others Page

Select<Others>

from the menu

Navigating to this page: