5-70

L30 Line Current Differential System

GE Multilin

5.3 REMOTE RESOURCES

5 SETTINGS

5

5.3REMOTE RESOURCES

5.3.1 REMOTE RESOURCES CONFIGURATION

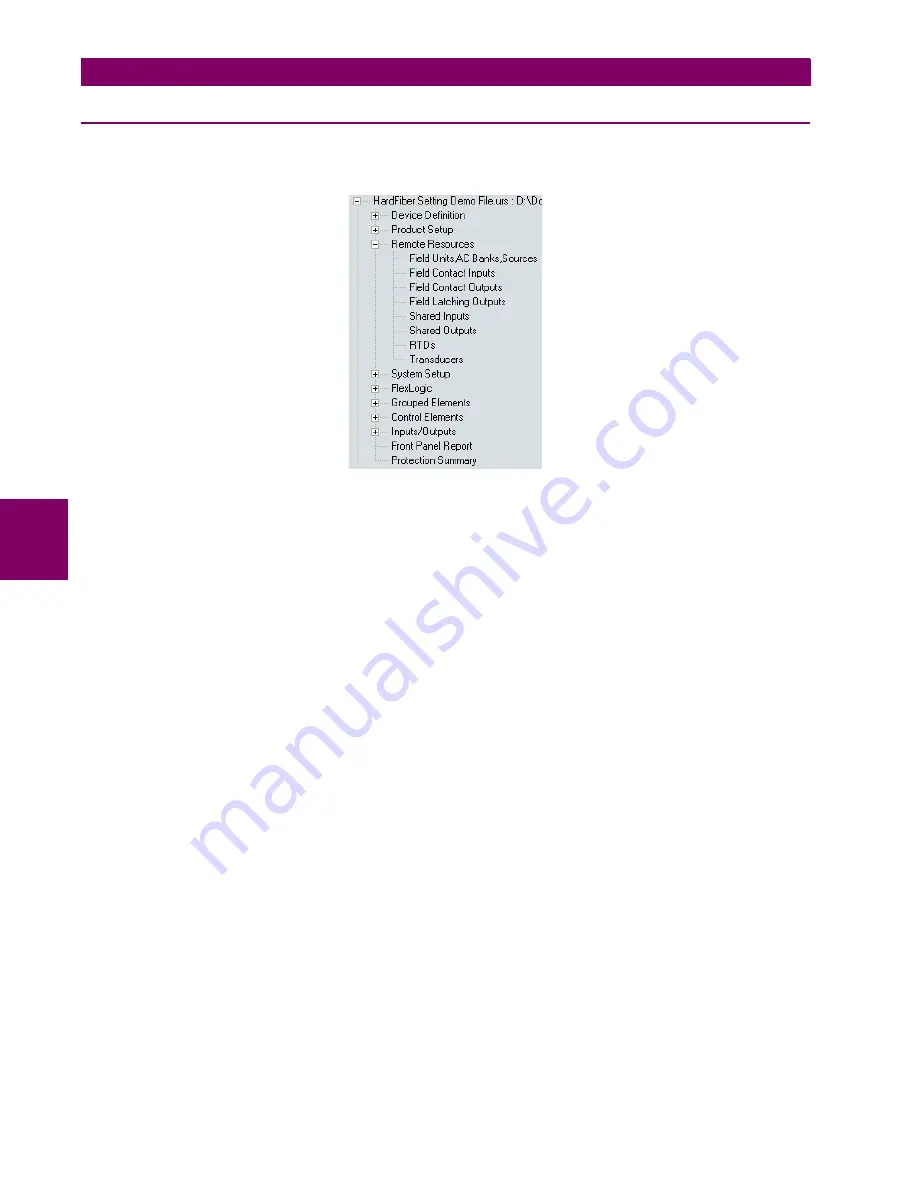

When L30 is ordered with a process card module as a part of HardFiber system, then an additional

Remote Resources

menu tree is available in EnerVista UR Setup software to allow configuration of the HardFiber system.

Figure 5–15: REMOTE RESOURCES CONFIGURATION MENU

The remote resources settings configure a L30 with a process bus module to work with HardFiber

Bricks

. Remote

resources configuration is only available through the EnerVista UR Setup software, and is not available through the L30

front panel. A Brick provides eight AC measurements, along with contact inputs, DC analog inputs, and contact outputs, to

be the remote interface to field equipment such as circuit breakers and transformers. The L30 with a process bus module

has access to all of the capabilities of up to eight Bricks. Remote resources settings configure the point-to-point connection

between specific fiber optic ports on the L30 process card and specific Brick. The relay is then configured to measure spe-

cific currents, voltages and contact inputs from those Bricks, and to control specific outputs.

The configuration process for remote resources is straightforward and consists of the following steps.

•

Configure the field units

. This establishes the point-to-point connection between a specific port on the relay process

bus module, and a specific digital core on a specific Brick. This is a necessary first step in configuring a process bus

relay.

•

Configure the AC banks

. This sets the primary and secondary quantities and connections for currents and voltages.

AC bank configuration also provides a provision for redundant measurements for currents and voltages, a powerful

reliability improvement possible with process bus.

•

Configure signal sources

. This functionality of the L30 has not changed other than the requirement to use currents and

voltages established by AC bank configuration under the remote resources menu.

•

Configure field contact inputs, field contact outputs, RTDs, and transducers as required for the application's functional-

ity

. These inputs and outputs are the physical interface to circuit breakers, transformers, and other equipment. They

replace the traditional contact inputs and outputs located at the relay to virtually eliminate copper wiring.

•

Configure shared inputs and outputs as required for the application's functionality

. Shared inputs and outputs are dis-

tinct binary channels that provide high-speed protection quality signaling between relays through a Brick.

For additional information on how to configure a relay with a process bus module, see GE publication number GEK-113658:

HardFiber Process Bus System Instruction Manual.

Summary of Contents for L30

Page 10: ...x L30 Line Current Differential System GE Multilin TABLE OF CONTENTS ...

Page 30: ...1 20 L30 Line Current Differential System GE Multilin 1 5 USING THE RELAY 1 GETTING STARTED 1 ...

Page 370: ...5 244 L30 Line Current Differential System GE Multilin 5 10 TESTING 5 SETTINGS 5 ...

Page 464: ...A 10 L30 Line Current Differential System GE Multilin A 1 PARAMETER LISTS APPENDIX A A ...

Page 600: ...C 30 L30 Line Current Differential System GE Multilin C 7 LOGICAL NODES APPENDIX C C ...

Page 610: ...D 10 L30 Line Current Differential System GE Multilin D 1 IEC 60870 5 104 APPENDIX D D ...

Page 622: ...E 12 L30 Line Current Differential System GE Multilin E 2 DNP POINT LISTS APPENDIX E E ...

Page 634: ...F 12 L30 Line Current Differential System GE Multilin F 3 WARRANTY APPENDIX F F ...

Page 644: ...x L30 Line Current Differential System GE Multilin INDEX ...