GE Multilin

F60 Feeder Protection System

5-281

5 SETTINGS

5.7 CONTROL ELEMENTS

5

i) THERMAL OVERLOAD PROTECTION

(ANSI 49)

PATH: SETTINGS

CONTROL ELEMENTS

MONITORING ELEMENTS

THERMAL OVERLOAD PROTECTION

THERMAL

PROTECTION 1(2)

The thermal overload protection element corresponds to the IEC 255-8 standard and is used to detect thermal overload

conditions in protected power system elements. Choosing an appropriate time constant element can be used to protect dif-

ferent elements of the power system. The cold curve characteristic is applied when the estimated

I

p

current is less than

10% of the base current. If

I

p

current is greater or equal than 10% than the base current, then the hot curve characteristic is

applied.

I

p

current is estimated with a fixed time constant for both cooling and heating that reaches to the final value in two

seconds on a step change (either step up or step down) signal.

The IEC255-8 cold curve is defined as follows:

(EQ 5.32)

The IEC255-8 hot curve is defined as follows:

(EQ 5.33)

In the above equations,

•

t

op

= time to operate

•

τ

op

= thermal protection trip time constant

•

I

= measured overload RMS current

•

I

p

= measured load RMS current before overload occurs

•

k

= IEC 255-8 k-factor applied to

I

B

, defining maximum permissible current above nominal current

THERMAL

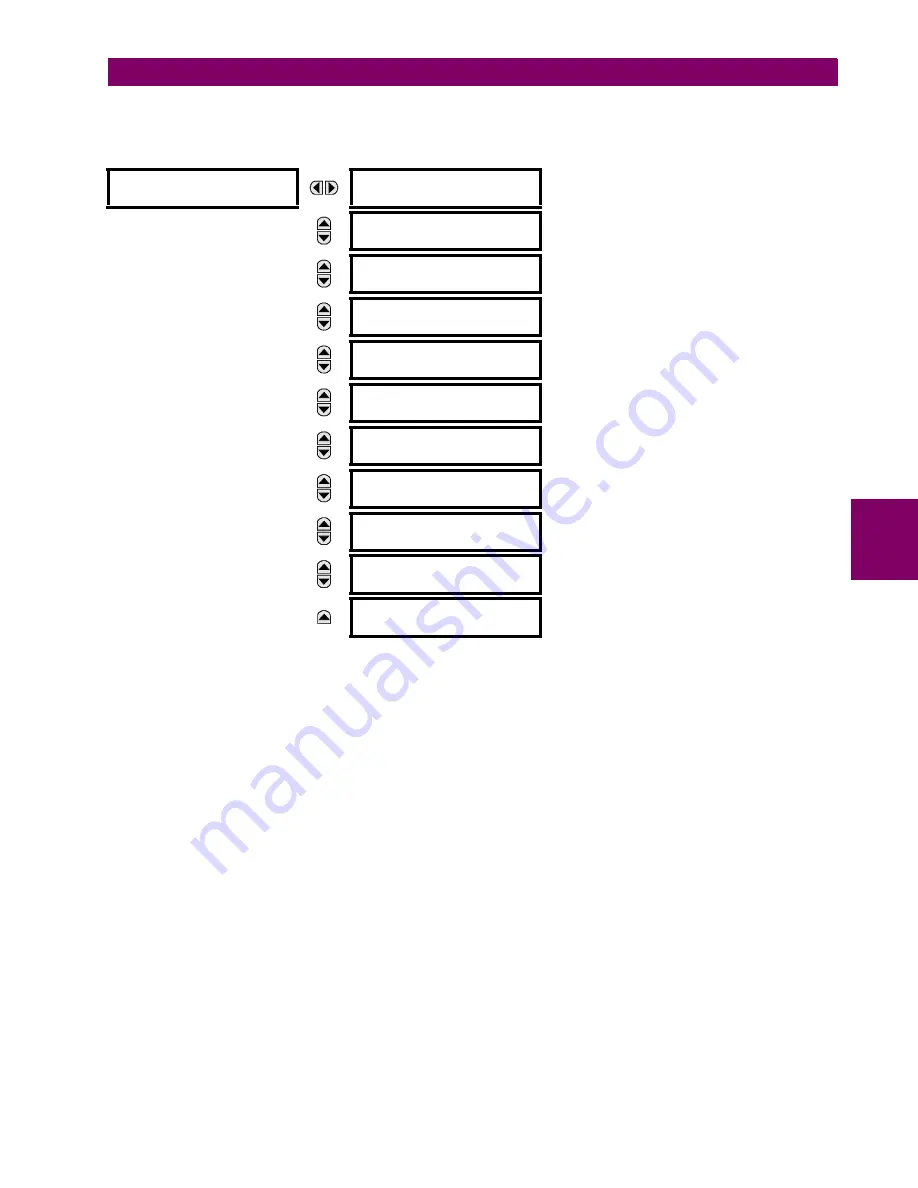

PROTECTION 1

THERMAL PROTECTION 1

FUNCTION: Disabled

Range: Disabled, Enabled

MESSAGE

THERMAL PROTECTION 1

SOURCE: SRC1

Range: SRC 1, SRC 2, SRC 3, SRC 4

MESSAGE

THERMAL PROTECTION 1

BASE CURR: 0.80 pu

Range: 0.20 to 3.00 pu in steps of 0.01

MESSAGE

THERMAL PROTECTION 1

k FACTOR: 1.10

Range: 1.00 to 1.20 in steps of 0.05

MESSAGE

THERM PROT 1 TRIP

TIME CONST: 45 min.

Range: 0 to 1000 min. in steps of 1

MESSAGE

THERM PROT 1 RESET

TIME CONST: 45 min.

Range: 0 to 1000 min. in steps of 1

MESSAGE

THERM PROT 1 MINIM

RESET TIME: 20 min.

Range: 0 to 1000 min. in steps of 1

MESSAGE

THERM PROT 1 RESET:

Off

Range: FlexLogic operand

MESSAGE

THERM PROT 1 BLOCK:

Off

Range: FlexLogic operand

MESSAGE

THERMAL PROTECTION 1

TARGET: Self-reset

Range: Self-reset, Latched, Disabled

MESSAGE

THERMAL PROTECTION 1

EVENTS: Disabled

Range: Disabled, Enabled

t

op

τ

op

I

2

I

2

kI

B

(

)

2

–

--------------------------

ln

×

=

t

op

τ

op

I

2

I

p

2

–

I

2

kI

B

(

)

2

–

--------------------------

ln

×

=

Summary of Contents for F60

Page 10: ...x F60 Feeder Protection System GE Multilin TABLE OF CONTENTS ...

Page 30: ...1 20 F60 Feeder Protection System GE Multilin 1 5 USING THE RELAY 1 GETTING STARTED 1 ...

Page 138: ...4 28 F60 Feeder Protection System GE Multilin 4 2 FACEPLATE INTERFACE 4 HUMAN INTERFACES 4 ...

Page 454: ...5 316 F60 Feeder Protection System GE Multilin 5 10 TESTING 5 SETTINGS 5 ...

Page 500: ...7 14 F60 Feeder Protection System GE Multilin 7 1 COMMANDS 7 COMMANDS AND TARGETS 7 ...

Page 508: ...8 8 F60 Feeder Protection System GE Multilin 8 2 FAULT LOCATOR 8 THEORY OF OPERATION 8 ...

Page 522: ...10 12 F60 Feeder Protection System GE Multilin 10 6 DISPOSAL 10 MAINTENANCE 10 ...

Page 660: ...B 116 F60 Feeder Protection System GE Multilin B 4 MEMORY MAPPING APPENDIX B B ...

Page 706: ...E 10 F60 Feeder Protection System GE Multilin E 1 IEC 60870 5 104 APPENDIX E E ...

Page 718: ...F 12 F60 Feeder Protection System GE Multilin F 2 DNP POINT LISTS APPENDIX F F ...

Page 728: ...H 8 F60 Feeder Protection System GE Multilin H 2 ABBREVIATIONS APPENDIX H H Z Impedance Zone ...

Page 730: ...H 10 F60 Feeder Protection System GE Multilin H 3 WARRANTY APPENDIX H H ...