www.fiberoptions.com

fiber@ge-interlogix.com

free phone: 800.342.3748

free fax: 877.342.3732

9

Also, a special “ramp” test pattern can be generated when the

S734DVT is placed in test mode.

This will verify proper functionality of the digital decoding

process as well as troubleshooting fiber optic interconnections.

To enable the test pattern generator, refer to Video Format/Test

Pattern Generator on page 5:

Test Mode

Test mode allows the user to verify the operation of the copper

receiver/driver circuit in an S734DV, as well as the fiber con-

nection from one S734DV to another. This allows the fiber

optic video path to be tested without a video source. Using the

test mode is simple:

1. On one of the S734DV units, set the rotary DATA SELECT

switch to position F (TEST MODE). At this end only, wire the

data connector as shown in Table 10.

NOTE:

The unit set to position F (TEST MODE) is the trans-

mitter during testing.

2. At the opposite end, set the S734DV rotary DATA SELECT

switch to position 9.

3. In the test mode, the test transmitter unit should behave as

follows:

a. The ENABLED LED is red, indicating that a valid data for-

mat has not been selected.

b. The DATA OUT LED is slowly flashing between amber,

green, and off. This indicates that the test mode is generating

an output pattern and sending it out on copper.

c. The DATA IN LED should mimic the DATA OUT LED.

This indicates that the data transmit/receive circuitry is work-

ing properly.

d. The LEVEL/LOSS

TM

LED indicates received fiber signal

strength.

4. The test receiver (position 9) should behave as follows:

a. The ENABLED LED is red, indicating that a valid data for-

mat has not been selected.

b. The DATA OUT LED is slowly flashing between amber,

green, and off. This indicates that the fiber path from the trans-

mitting unit is set for TEST MODE is reliable.

c. The DATA IN LED should be off since there is no input

copper connection made.

d. The LEVEL/LOSS

TM

LED is green indicating that suffi-

cient optical power is being received.

When the test is completed, run the test again in the opposite

direction by changing DATA SELECT switch positions and

connectors. Successful completion of the test indicates both

units are operating correctly.

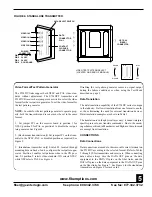

LED Operation

Refer to the Table 12 for an explanation of how to diagnose

system faults using the LEDs built into the Fiber Options units.

The S734DV has 7 LED indicators that are very useful in

describing the current state of operation, as well as the current

status of data flow and fiber optic signal strength. These indi-

cators are LASER, LEVEL /LOSS

TM

, VIDEO IN (or OUT),

DATA IN (or OUT), CONTACT, and ENABLED. See Figure

9. They function as follows:

LASER Indicator

The LASER LED indicates the status of the laser. A green

LASER LED indicates the laser is operating normally. A red

LASER LED indicates the laser is malfunctioning.

LEVEL/LOSS

TM

Indicator

This LED is useful for indicating the relative optical signal

strength at the fiber optic receiver. When sufficient optical

power is being received, the LED is green. If no or insufficient

optical power is received, the LED will be red. All data will

default to it's failure state level to eliminate bus contention.

TABLE 11: ON SCREEN DIAGNOSTICS

Monitor Display

Meaning

Single white bar

No video input to transmitter

Double white bar

No optical input to receiver

Ramp test pattern

Testmode (Position E or F) selected at transmitter