2 INSTALLATION

g

GE Power Management

21

2.22 169 Drawout Relay

The model 169 and 169 Plus relays are available in a drawout case option. The operation of the relay is the same

as described elsewhere in this manual except for the differences noted in this section. The physical dimensions of

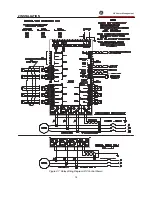

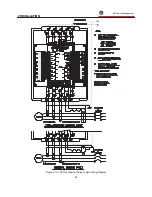

the drawout relay are as shown in Figure 2-10. The relay should be mounted as shown in Figure 2-11.

The drawout 169 relay can be removed from service without causing motor shut-down. This can be useful for

replacing, calibrating, or testing units.

RELAY MOUNTING - Make cutout as shown and drill six 7/32" holes on mounting panel. Approximately 2-1/2"

should be clear at the top and bottom of the cutout in the panel for the hinged door. Ensure that the five #6-32 nuts

are removed from the threaded studs in the mounting flange and that the drawout chassis has been removed from

the drawout case. Install the case from the rear of the mounting panel by aligning the five #6-32 threaded case

studs to the previously drilled holes. With the studs protruding through the holes secure the case on the right hand

side with two #6-32 nuts provided. Install the hinged door on the front of the mounting panel using three #6-32 nuts

provided. There must be at least 1/2" clearance on the hinged side of the drawout relay to allow the door to open.

RELAY REMOVAL - Open the hinged door. Next remove the two ten finger connecting plugs making sure the top

one is removed first. Swivel the cradle-to-case hinged levers at each end of the 169 cradle assembly and slide the

assembly out of the case.

RELAY INSTALLATION - Slide the 169 cradle assembly completely into the case. Swivel the hinged levers in to lock

the 169 cradle assembly into the drawout case. Install the two ten finger connecting plugs making sure the bottom

plug is installed first. Close the hinged door and secure with the captive screw.

IMPORTANT NOTE: When removing the drawout relay cradle assembly the top ten finger connecting plug must be

withdrawn first. This isolates the 169 output relay contacts before power is removed from the relay. When installing

the drawout relay cradle assembly the bottom ten finger connecting plug must be installed first. This causes power

to be applied to the 169 relay before the output relay contacts are placed in the circuit.

After a 169 relay cradle assembly has been removed from the drawout case it is recommended that the hinged door

be closed in order to reduce the risk of electric shock.

Due to the hardware configuration of the drawout relay shorting bars, the RELAY FAILSAFE CODE (SETPOINTS,

page 5) should not be changed without consulting the factory. Wiring for the 169 Plus drawout is shown in Figure 2-

12. If it is required that any of the output relay configurations in Figure 2-12 be different than shown, this information

must be stated when the relay is ordered.

Summary of Contents for 169

Page 12: ......

Page 14: ...2 INSTALLATION g GE Power Management 8 Figure 2 2 CT Dimensions ...

Page 17: ...2 INSTALLATION g GE Power Management 11 Figure 2 4 Relay Wiring Diagram AC control power ...

Page 19: ...2 INSTALLATION g GE Power Management 13 Figure 2 6 Relay Wiring Diagram Two Phase CTs ...

Page 20: ...2 INSTALLATION g GE Power Management 14 Figure 2 7 Relay Wiring Diagram DC Control Power ...

Page 28: ...2 INSTALLATION g GE Power Management 22 Figure 2 10 169 Drawout Relay Physical Dimensions ...

Page 29: ...2 INSTALLATION g GE Power Management 23 Figure 2 11 169 Drawout Relay Mounting ...

Page 31: ...3 SETUP AND USE g GE Power Management 25 Figure 3 1 Front Panel Controls and Indicators ...

Page 73: ...3 SETUP AND USE g GE Power Management 67 Figure 3 2 Standard Overload Curves ...

Page 74: ...3 SETUP AND USE g GE Power Management 68 A B Figure 3 3 Custom Curve Examples ...

Page 88: ...5 THEORY OF OPERATION g GE Power Management 82 Figure 5 1 Hardware Block Diagram ...

Page 90: ...5 THEORY OF OPERATION g GE Power Management 84 Figure 5 2 Firmware Block Diagram ...