4 RELAY TESTING

g

GE Power Management

79

4.4 Ground Fault Current Functions

The ground fault current function uses digital current information converted from the analog ground fault CT input.

The 169 relay must read the injected ground fault current correctly in order for the ground fault function to operate

properly. Using factory default setpoints to test the ground fault input circuitry, pass a phase current conductor

through the ground fault CT window as shown in figure 4-1. The actual injected current should then be the same as

the "GROUND FAULT CURRENT" display in ACTUAL VALUES mode. If the injected current is adjusted to over 4.0

Amps for longer than 10.0 seconds the ground fault alarm should become active. If over 8.0 Amps is injected for

more than 50 msec. a ground fault trip should occur. These tests can be performed for other CT ratios and

setpoints.

4.5 RTD Measurement Tests

The correct operation of each of the RTD inputs can be tested by simulating RTDs with potentiometers. To test a

169 relay configured for use with 100 platinum RTDs, 100 potentiometers and resistors can be used. These

should be connected to each RTD as shown in figure 4-1.

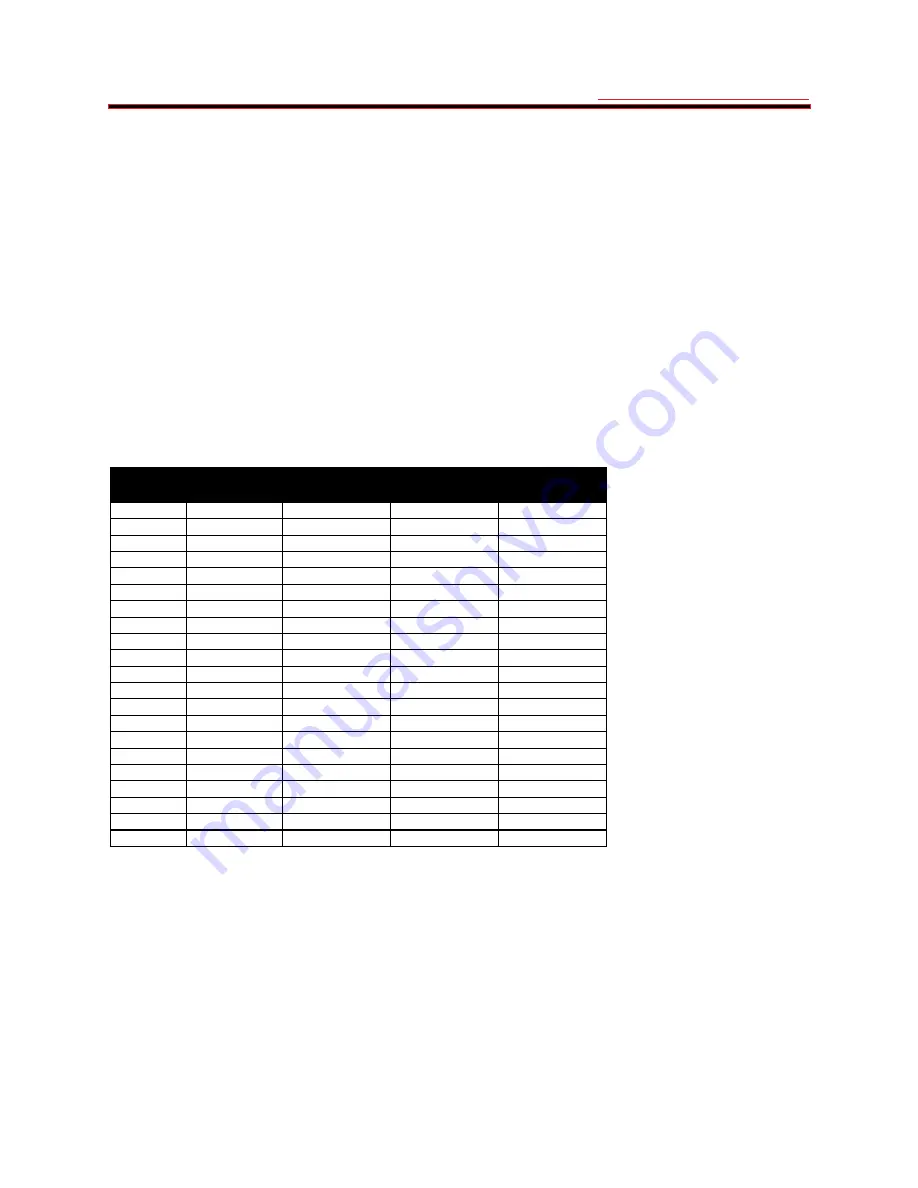

Table 4-1 shows RTD resistances for various temperatures. Individual, actual stator and bearing RTD temperatures

can be viewed in ACTUAL VALUES mode, page 2.

To test overtemperature trip/alarm functions the simulated RTD potentiometers should be adjusted to correspond to

high RTD temperatures.

Table 4-1 RTD Resistance vs. Temperature

RESISTANCE (IN OHMS)

TEMP °C

100

Ω

Pt

120

Ω

Ni

100

Ω

Ni

100

Ω

Cu

0

100.00

120.00

100.00

9.04

10

103.90

127.17

105.97

9.42

20

107.79

134.52

112.10

9.81

30

111.67

142.06

118.38

10.19

40

115.54

149.79

124.82

10.58

50

119.39

157.74

131.45

10.97

60

123.24

165.90

138.25

11.35

70

127.07

174.25

145.20

11.74

80

130.89

182.84

152.37

12.12

90

134.70

191.64

159.70

12.51

100

138.50

200.64

167.20

12.90

110

142.29

209.85

174.87

13.28

120

146.06

219.29

182.75

13.67

130

149.82

228.96

190.80

14.06

140

153.58

238.85

199.04

14.44

150

157.32

248.95

207.45

14.83

160

161.04

259.30

216.08

15.22

170

164.76

269.91

224.92

15.61

180

168.47

280.77

233.97

16.00

190

172.46

291.96

243.30

16.39

200

175.84

303.46

252.88

16.78

4.6 Power Failure Testing

When the AC voltage applied to the 169 relay decreases to below about 90 V the relay SERVICE L.E.D. should

become illuminated. All output relays will also go to their power down states. To test the memory circuitry of the

relay, remove and then re-apply control power. All stored setpoints and statistical data should be unchanged. The

displayed lock-out time after an overload trip should continue to decrease even when control power is removed.

Summary of Contents for 169

Page 12: ......

Page 14: ...2 INSTALLATION g GE Power Management 8 Figure 2 2 CT Dimensions ...

Page 17: ...2 INSTALLATION g GE Power Management 11 Figure 2 4 Relay Wiring Diagram AC control power ...

Page 19: ...2 INSTALLATION g GE Power Management 13 Figure 2 6 Relay Wiring Diagram Two Phase CTs ...

Page 20: ...2 INSTALLATION g GE Power Management 14 Figure 2 7 Relay Wiring Diagram DC Control Power ...

Page 28: ...2 INSTALLATION g GE Power Management 22 Figure 2 10 169 Drawout Relay Physical Dimensions ...

Page 29: ...2 INSTALLATION g GE Power Management 23 Figure 2 11 169 Drawout Relay Mounting ...

Page 31: ...3 SETUP AND USE g GE Power Management 25 Figure 3 1 Front Panel Controls and Indicators ...

Page 73: ...3 SETUP AND USE g GE Power Management 67 Figure 3 2 Standard Overload Curves ...

Page 74: ...3 SETUP AND USE g GE Power Management 68 A B Figure 3 3 Custom Curve Examples ...

Page 88: ...5 THEORY OF OPERATION g GE Power Management 82 Figure 5 1 Hardware Block Diagram ...

Page 90: ...5 THEORY OF OPERATION g GE Power Management 84 Figure 5 2 Firmware Block Diagram ...