10

WHAT YOU WILL NEED

• Copper or GE SmartConnect

™

Refrigerator Tubing kit,

1/4” outer diameter to connect the refrigerator to the

water supply. If using copper, be sure both ends of the

tubing are cut square.

To determine how much tubing you need: measure the

distance from the water valve on the back of the

refrigerator to the water supply pipe. Then add 8’

(2.4 m). Be sure there is sufficient extra tubing

(about 8’ [2.4 m] coiled into 3 turns of about 10”

[25 cm] diameter) to allow the refrigerator to move out

from the wall after installation.

INSTALLING THE WATER LINE

(ON SOME MODELS)

Installation Instructions

BEFORE YOU BEGIN

Recommended copper water supply kits are WX8X2,

WX8X3 or WX8X4, depending on the amount of tubing

you need. Approved plastic water supply lines are GE

SmartConnect

™

Refrigerator Tubing (WX08X10006,

WX08X10015 and WX08X10025).

When connecting your refrigerator to a GE Reverse

Osmosis Water System, the only approved installation is

with a GE RVKit. For other reverse osmosis water

systems, follow the manufacturer’s recommendations.

This water line installation is not warranted by the

refrigerator or icemaker manufacturer. Follow these

instructions carefully to minimize the risk of expensive

water damage.

Water hammer (water banging in the pipes) in house

plumbing can cause damage to refrigerator parts and

lead to water leakage or flooding. Call a qualified

plumber to correct water hammer before installing

the water supply line to the refrigerator.

To prevent burns and product damage, do not hook up

the water line to the hot water line.

If you use your refrigerator before connecting the water

line, make sure the switch is set to OFF or the feeler arm

in the STOP (up) position.

Do not install the icemaker tubing in areas whe re

temperatures fall below freezing.

When using any electrical device (such as a power drill)

during installation, be sure the device is double insulated

or grounded in a manner to prevent the hazard of

electric shock, or is battery powered.

All installations must be in accordance with local

plumbing code requirements.

1

WHAT YOU WILL NEED

(CONT.)

GE SmartConnect

™

Refrigerator Tubing Kits are available

in the following lengths:

6’ (1.8 m)

– WX08X10006

15’ (4.6 m)

– WX08X10015

25’ (7.6 m)

– WX08X10025

Be sure that the kit you select allows at least 8’ (2.4 m) as

described above.

NOTE: The only GE approved plastic tubing is that

supplied in GE SmartConnect

™

Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Certain

types of plastic will crack or rupture with age and

cause water damage to your home.

• A GE water supply kit (containing tubing, shutoff valve

and fittings listed below) is available at extra cost from

your dealer or from Parts and Accessories,

1.800.661.1616.

• A cold water supply. The water pressure must be

between 20 and 120 p.s.i. (1.4–8.1 bar).

• Power drill.

• 1/2” or adjustable wrench.

• Straight and Phillips

blade screwdriver.

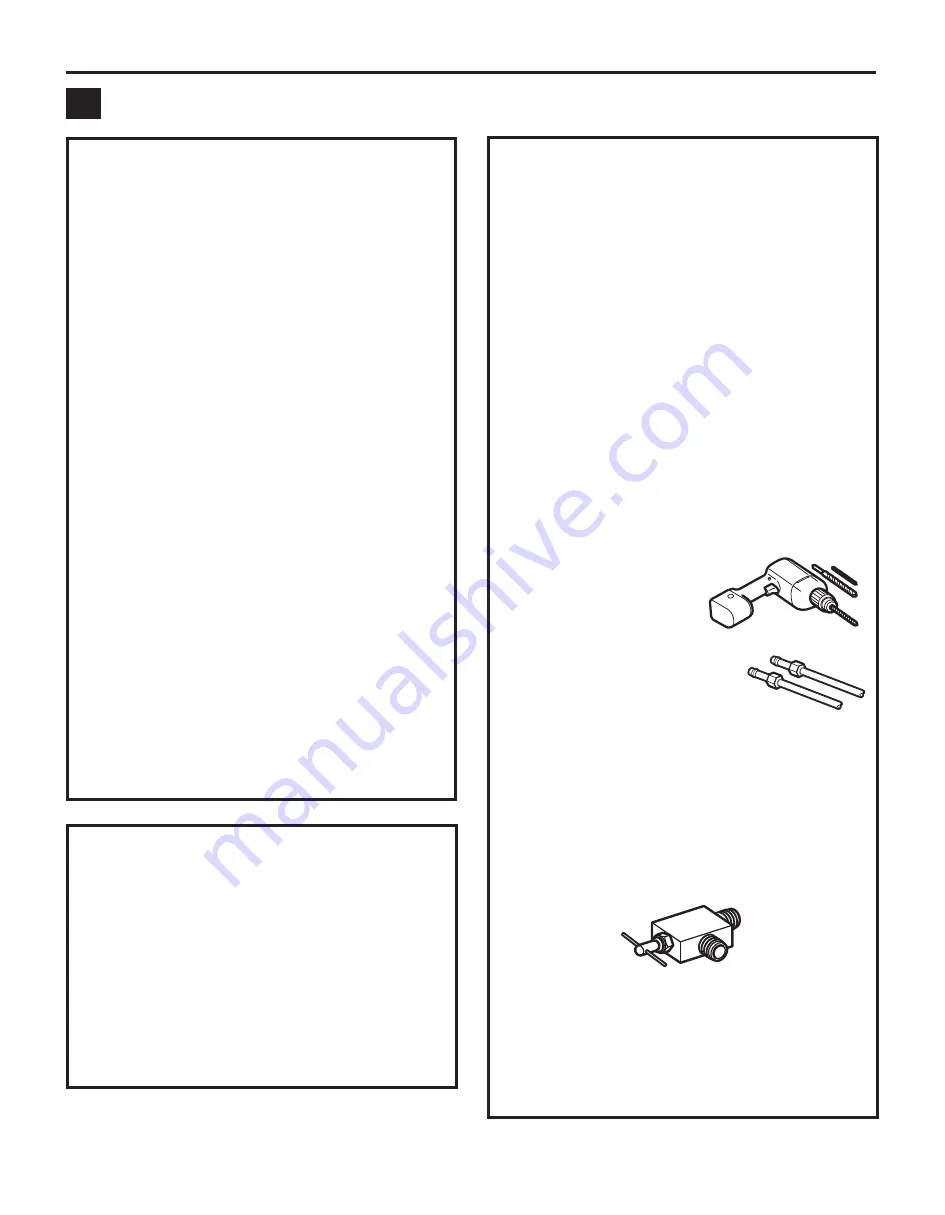

• Two 1/4” outer diameter compression nuts and

2 ferrules (sleeves)—to connect

the copper tubing to the shutoff

valve and the refrigerator water valve.

OR

• If you are using a GE SmartConnect

™

Refrigerator

Tubing kit, the necessary fittings are preassembled

to the tubing.

• If your existing copper water line has a flared fitting at

the end, you will need an adapter (available at

plumbing supply stores) to connect the water line to

the refrigerator OR you can cut off the flared fitting

with a tube cutter and then use a compression fitting.

Do not cut formed end from GE SmartConnect

™

Refrigerator tubing.

• Shutoff valve to connect to the cold water line.

The shutoff valve should have a water inlet with a

minimum inside diameter of 5/32” at the point of

connection to the COLD WATER LINE. Saddle-type

shutoff valves are included in many water supply kits.

Before purchasing, make sure a saddle-type valve

complies with your local plumbing codes.