g

GE

OPM_SGS_ISG_M22_M30_0US_V011.doc

34/38

Installation

Guide

SG Series

225 & 300 kVA

4 CUSTOMER

INTERFACE

4.1 CUSTOMER

INTERFACE

Serial port J3 - RS 232 (sub D - female 9 pin)

Suitable for JUMP protocol

Pin 2

: TX (out)

Pin 3

: RX (in)

Pin 5

: GND

J2 (subD-female 25p) – Output signals on voltage free contacts

J2

/

1, 2, 3

- NO,

C,

NC

- Utility

Failure

(def. Param. RL=1)

J2/4, 5, 6

- NO,

C,

NC

- Load on Inverter

(def. Param. RL=3)

J2/7, 8, 9

- NO,

C,

NC

- Stop Operation

(def. Param. RL=5)

J2/14, 15, 16

- NO,

C,

NC

- Load

on

Utility

(def.

Param.

RL=2)

J2/17, 18, 19

- NO,

C,

NC

- General Alarm

(def. Param. RL=4)

J2/20, 21, 22

- NO,

C,

NC

- Acoustic Alarm

(def. Param. RL=6)

Signals on terminals

X1

and on connector

J2

are in parallel

and therefore not separated galvanically from each other.

The programmable signals on

X1

and

J2

will be disabled with

Q1

open, with

the exception of the signals for

“16 - Manual Bypass ON”

and

“26 - EPO”

.

XB - Terminals for EPO connection

X2 / 1, 2

or

J2 / 12, 25

NC

EPO (Emergency Power Off)

Note: to enable this function, remove cable short-circuiting XB / 2 – 3 and

the Jumper JP3 on P4 – Customer Interface

.

X1 – Output signals on voltage free contacts - terminals

X1/1, 2, 3

- NO,

C,

NC

- Utility

Failure

(def. Param. RL=1)

X1/4, 5, 6

- NO,

C,

NC

- Load on Inverter

(def. Param. RL=3)

X1/7, 8, 9

- NO,

C,

NC

- Stop

Operation

(def.

Param.

RL=5)

X1/12, 13, 14

- NO,

C,

NC

- Load on Utility

(def. Param. RL=2)

X1/15, 16, 17

- NO,

C,

NC

- General

Alarm

(def.

Param.

RL=4)

X1/18, 19, 20

- NO,

C,

NC

- Acoustic

Alarm

(def.

Param.

RL=6)

Input contacts

X1/10, 21

or

J2/10, 23

Programmable (default = RL1)

X1/11, 22

or

J2/11, 24

Programmable / Generator ON (NO) (def. = RL2)

1

12

1

3

2

14

3

15

4

16

5

17

6

18

7

19

8

20

9

21

10

22

11

1

14

9

1

X1

J2

J3

SG

S_225

-300_Cust

ome

r i

nte

rfac

e_

01

J5

J4

XA

2

1

1

2

3

4

JP3

XB

1

2

3

4

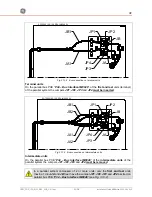

Fig. 4.1-1 Customer interface

NO

= normally open

C

= common

NC

= normally closed

The connectors

J4

and

J5

can be used for additional

SNMP Card

,

Environmental

Card

(not available yet)

or an additional

Customer Interface

(installation only when the UPS is switched Off).

XA

: terminals for 24VDC Auxiliary Power Supply connection.

XB

: terminals for EPO connection.

Programmable user relays

Programmable functions on contacts (X1 - J2)

On terminals

X1

or

J2

connector, six of the following

26

signals

can be selected from the display, entering with the

appropriate

password

.

0- No Information

1- Buzzer

2- General Alarm

3- Load on Utility

4- Stop Operation

5- Load on Inverter

6- Utility Failure

7- DC Over Voltage

8- Low Battery

9- Overload

10- Over Temperature

11- Inverter-Utility not syncr.

12- Bypass Locked

13- Bypass Utility Failure

14- Rectifier Utility Failure

15- Battery Discharge

16- Manual Bypass ON

17- Rectifier ON

18- Inverter ON

19- Boost Charge

20- Battery Earth Fault

21- Battery Fault

22- Relay Input 1

23- Relay Input 2

24- Relay Output ON

25- Relay Output OFF

26- EPO (Emergency

Power Off)

Some UPS functions can be activated with

parameters when an external Normally Open

contact is closed on:

X1-10, 21 / J2-10, 23

or

X1-11, 22 / J2- 11, 24

Selectable functions by changing

parameters

(password required) are:

0 - No function

1 - Inverter ON

2 - Inverter OFF

3 - Print All

4 - Status Relay

5 - Generator ON

6 - External Bypass ON

7 - External Battery Fuses, or External K3.

See Alarm 4104 - “Battery Fuses”.

Voltage free contacts:

Max. DC / AC: 24V / 1.25A

IEC 950 (SELV circuit)

Min. Signal Level: 5VDC/50mA