4 |

GE Oil & Gas

© 2014 General Electric Company. All rights reserved.

Description

The spring-diaphragm actuator is a simple, powerful,

mechanical device. There are two general types:

Air-to-Extend Stem and Air-to-Retract Stem. Actuators

are designated by case size: Nos. 9, 11, 13, 15, 18

and 18L.

The nominal range of a spring-diaphragm actuator is

the air pressure range in pounds per square inch (psi)

for rated stroke under no load. Common ranges are

3–15 psi and 6–30 psi. The spring range and maximum

allowable supply pressure are marked on the serial

plate. For a 3–15 psi nominal range, the stem will start

to stroke when the air pressure reaches 3 psi, and will

complete the stroke when the pressure reaches 15 psi

(plus or minus 5%).

In the air-to-extend actuator, conformation of the

molded diaphragm to the diaphragm plate serves as

a flexible upper guide for the actuator stem (26). The

lower guide is an oil-impregnated bronze bushing (37)

located in the spring adjustor (36). The air-to-retract

actuator differs from the air-to-extend unit in that the

spring (22), spring barrel (71) and spring adjustor (36) are

located above the diaphragm plate (40) and diaphragm

(39) which are inverted. A gasket (19) at the joint of the

diaphragm case and yoke and a packing box around

the actuator stem prevents air leakage. The diaphragm

acts as a flexible upper guide and the packing box

assembly as the lower guide for the actuator stem.

Air connections are 1/4" NPT. Connections are located in

the upper diaphragm case (air-to-extend actuators) or

yoke (air-to-retract actuators).

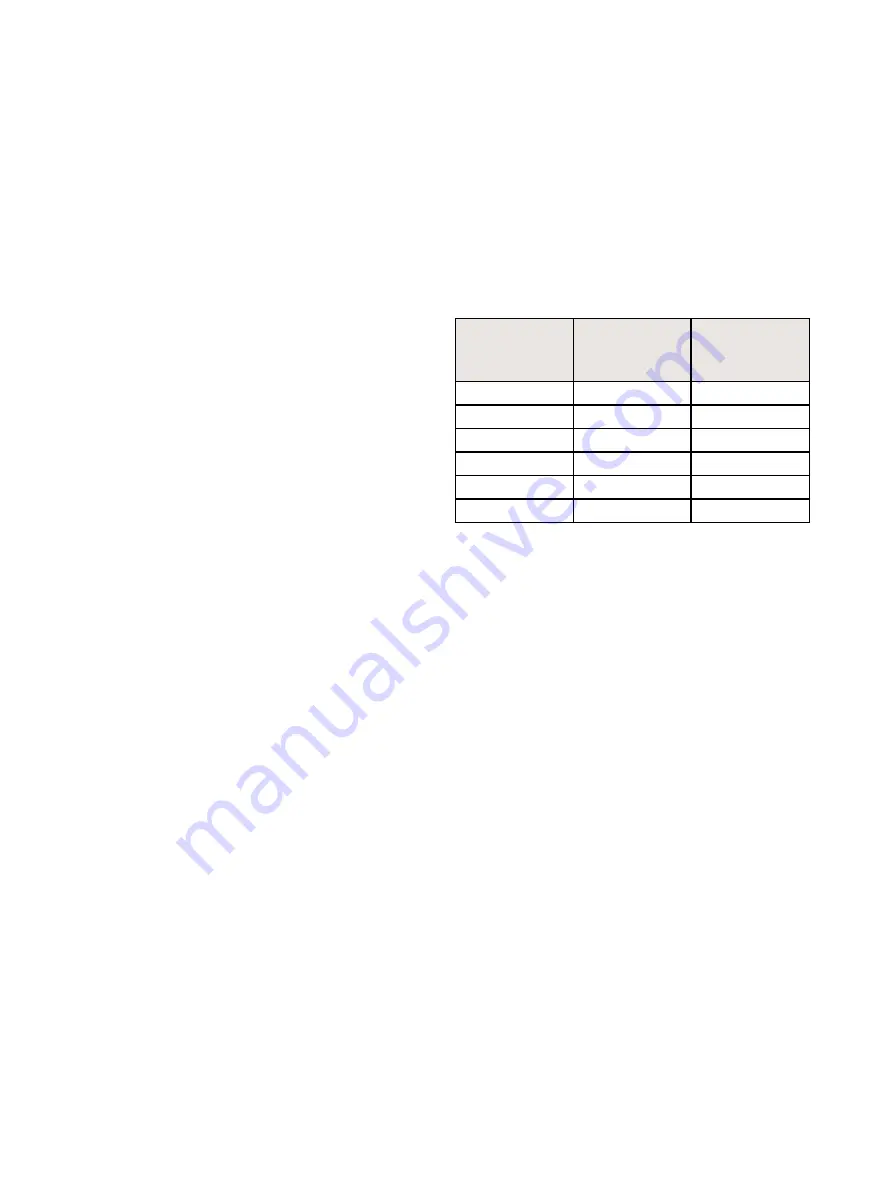

Standard

Actuator Size

Effective

Diaphragm

Area (sq. in.)

Maximum

Stroke (in.)

9

45

¾

11

71

1

13

105

1

½

15

145

2

18

200

2

½

18L

200

4

Maintenance

Air-to-Extend Actuators (Type 37)

Diaphragm Replacement. Before disassembling the

actuator, all spring compression should be relieved

by turning the spring adjustor (36), to prevent the

upper case popping up when the cap screws (45) are

removed. This is especially important on actuators

with a high initial spring setting. Remove cap screws

(45), nuts (46) and upper diaphragm case (43). Remove

nut (30) and washer (41) to release the diaphragm (39).

If possible, the replacement diaphragm should be of

the molded type supplied by Masoneilan, but in an

emergency a diaphragm may be cut from flat sheet

stock for up to and including No. 15 actuators. To allow

sufficient stroke without restriction due to flatness of

the diaphragm, the diaphragm bolt circle should be

about 10% greater than that of the diaphragm case.

Replace washer (41), nut (30) and upper diaphragm

case.

Spring Adjustment. An air supply, with a gauge and

regulator, should be piped to the upper diaphragm

case for this adjustment. Adjust spring compression so

that the actuator sem (26) just begins to move when

air pressure reaches minimum pressure of the range

stamped on the serial plate. This movement is most

easily detected by feeling the stem as air pressure is

applied.

Note: Adjust spring compression only when

there is no air pressure on diaphragm.

Air-to-Retract Actuators (Type 38)

Diaphragm Replacement. The procedure is the same

as for air-to-extend actuators except that the entire

upper case assembly (including spring barrel (71), spring

(22), spring seats (33 and 34), nut (30) and diaphragm

plate (40) must be removed to release the diaphragm.

Install a new diaphragm and reassembly the above

parts.

Spring Adjustment. The procedure is identical with that

for air-to-extend actuators except that supply air is

piped to the 1/4" port in the yoke.

Packing Box. The packing box is subject to low air

pressure only and requires minimum maintenance.

The packing rings have a square section and are made

of carbon core with braided PTFE jacket. The packing

may be added to or completely replaced without

disassembling either the actuator or the mechanism (or

valve) to which it is attached. Be sure to tighten packing

nut (20) lightly. Over-tightening will cause excessive

friction, resulting in sluggish performance.