14

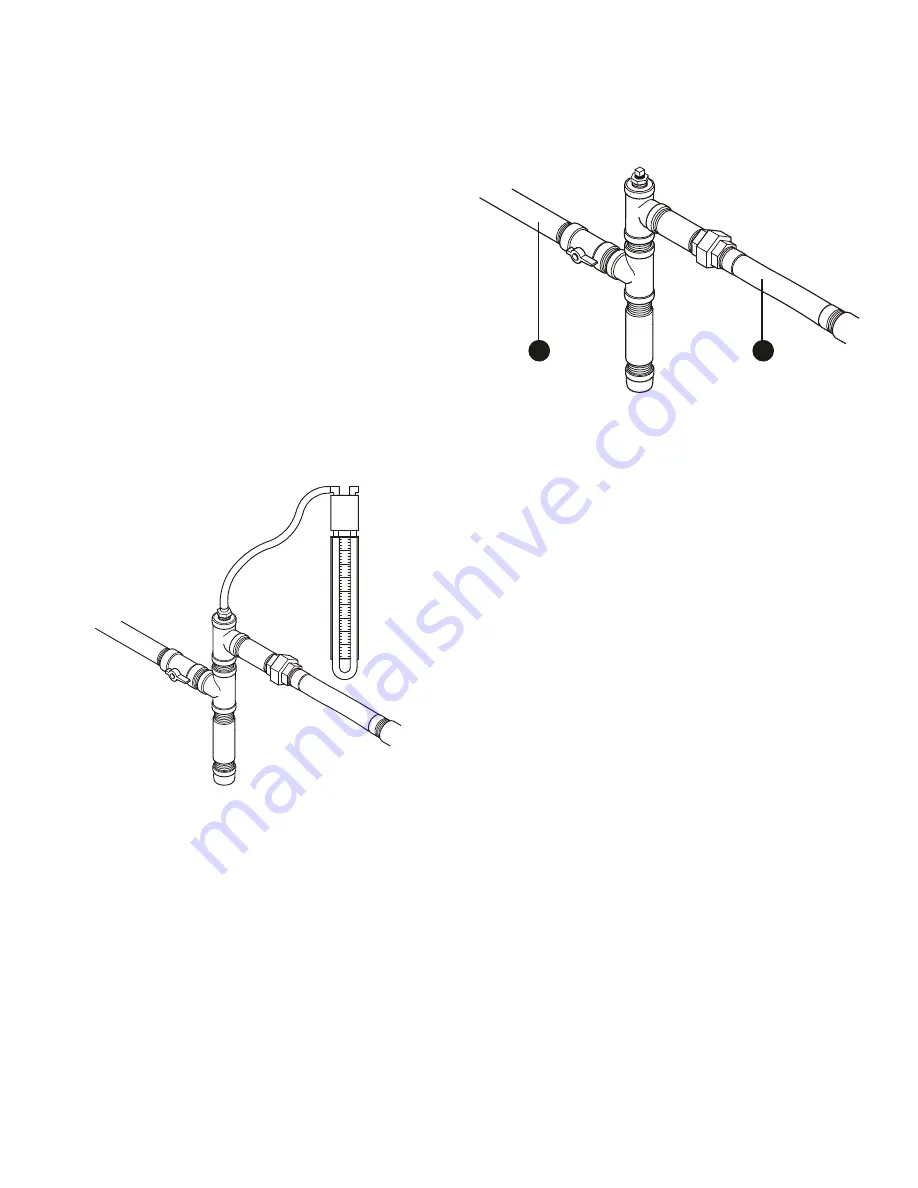

When the initial test runs are completed, the manometer

is removed and the port is plugged. A typical final fuel

connection assembly is shown here, where (

a

) is the fuel

supply and (

B

) goes to the home generator.

It is recommended that the fuel connection incorporate the

following components:

• A minimum 10 ft. (3 m) section of gas pipe between

the primary fuel regulator and the generator fuel inlet

connection (acts as accumulator for high block loads).

• A manual fuel shut-off valve located in the interior of

the building.

• A manual fuel shut-off valve located outside the

building, just before the generator unit.

• Where the formation of hydrates or ice is known to

occur, piping should be protected against freezing.

The termination of hard piping should include

a sediment trap where condensate is not likely

to freeze.

• A manometer port should be provided.

The manometer port permits temporary installation of

a manometer to ensure that the engine receives the

correct fuel pressure to operate efficiently throughout its

operating range.

fuel Pipe sizing

There are numerous on-line or otherwise-published

references for fuel pipe sizing. For example, NFPA 54 -

National Fuel Gas Code, 2006 (Item #: 320-6031-06) is a

common resource. The installer should consider the specific

gravity of gas and compensate for a nominal amount of

restriction from bends, fittings, etc. If an unusual number of

fittings, bends, or other restrictions are used, refer to federal

and local codes for guidance.

A

B