23

fuel conversion

The unit is shipped from the factory calibrated for NG or LP

vapor operation. To convert the engine from NG to LP vapor

or from LP vapor to NG operation, follow these steps:

1. Set generator circuit breaker to

off

2. Set control panel system switch to

off

3. Remove 15 Amp fuse from system control panel.

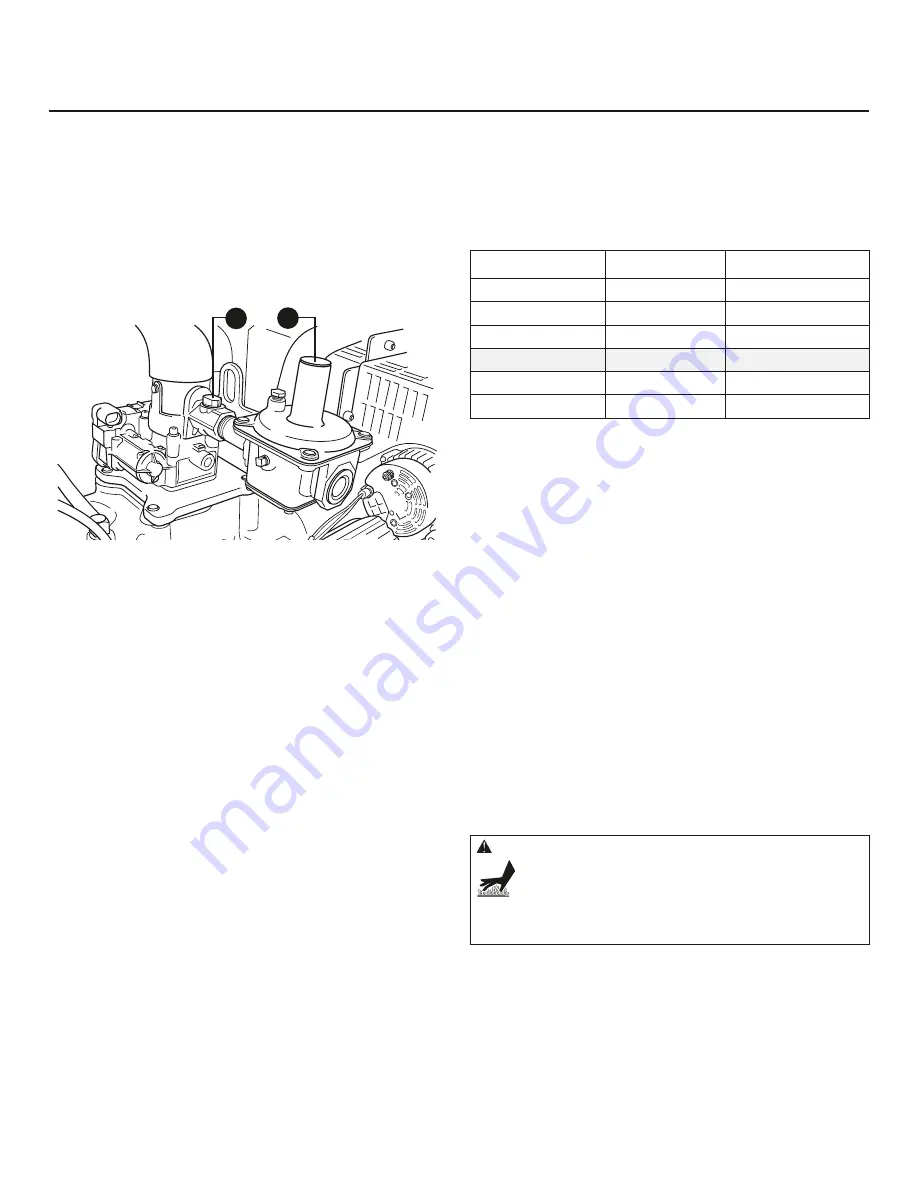

4. Remove Zero Pressure Regulator (ZPR) tower cap (

a

).

The Main Adjust control is shown as (

B

).

5. Calibrate O

2

sensor per Analyzer manufacturer

specification. Install O

2

sensor into exhaust pipe.

(Note: technician supplies O

2

sensor and analyzer)

6. Attach timing light to #1 spark plug on engine (see

engine manual for diagram).

7 In control panel enclosure, “OPEN” fuel selector

jumper for NG operation and “CLOSE” connector

for LP operation. See schematic or wire diagram for

further information.

8. Re-install 15 Amp fuse in system control panel.

9. Set generator circuit breaker to

on

10. Set control panel system switch to

auto

11. After purging fuel supply line, push

ManuaL oVer-riDe

button on control panel for six

seconds. When engine starts, allow unit to warm up

for ten minutes under no load.

note

: If utility power is not connected, the generator

will start automatically.

12. Using technician-supplied timing light, locate timing

marks on crankshaft vibration dampener.

13. If timing is not within specification, loosen distributor

hold-down clamp. While observing timing indicator,

adjust distributor as listed below

LP

=

24

degrees before top dead center

nG

=

32

degrees before top dead center

note

: Timing values are approved by PSI Engineering.

14. Tighten distributor hold-down clamp.

15. While observing O

2

Analyzer readout, adjust zero

pressure (

a

) and main adjustment (

B

) screws to obtain

stoichiometric value shown in table. Select table value

that corresponds to your O

2

Analyzer display. The

shaded line in table indicates optimum target value.

Voltage

Phi

Lamda

2.40

1.000

1.000

2.45

1.012

0.988

2.50

1.024

0.977

2.55

1.036

0.966

2.60

1.048

0.955

2.65

1.060

0.944

16. Using technician-supplied load, add half load to

generator. Check and adjust (

a

) and (

B

) to achieve

target value.

17. Using technician-supplied load, add full load to

generator. Check and adjust (

a

) and (

B

) to achieve

target value.

18. Remove load and check if sensor value remained

in target area. If needed, adjust (

a

) and (

B

) to achieve

target value.

19. Add half, then full load to generator. Recheck and

verify sensor value remains in target area.

iMPortant

: It may take several attempts to achieve the

target setting. Continue to test and adjust with engine

stabilized at no, half and full loads until target value is

achieved at all generator loads.

20. Remove load from generator. Allow generator to

run for ten minutes to stabilize internal temperatures.

Turn control panel system switch to

off

.

21. Remove 15 Amp fuse from system control panel.

22. Install the ZPR tower cap, remove O

2

sensor, and

timing light.

23. Re-install fuse in system control panel.

24. Set exercise timer.

25. Complete emissions statement and send with

installation checklist.

WarninG

Contact with muffler and engine parts can result in

serious burns.

DO NOT touch hot parts and AVOID hot exhaust gases.

•

Allow equipment to cool before touching.

•

B

A